In the field of gold mining and extraction, traditional sodium cyanide has long held an important position. However, the highly toxic nature of sodium cyanide poses great risks to the environment and human safety. With the continuous enhancement of environmental awareness and the increasing strictness of relevant regulations, the search for a safe, environmentally friendly and efficient alternative has become extremely urgent. The environmental-friendly gold leaching agent has emerged as the times require, bringing new hope and changes to the gold ore extraction industry.

Extraction Method of Environmental-friendly Gold Leaching Agent

The extraction process of the environmental-friendly gold leaching agent follows a rigorous and scientific procedure. Firstly, lime or other alkalis are used to adjust the alkalinity of the ore body or pulp, precisely adjusting the pH value to 11 - 12. This alkalinity adjustment is of great significance as it creates a suitable chemical environment for the subsequent leaching reaction. In large-scale leaching operations, a solution of the appropriate concentration should be carefully prepared according to the suitable leaching concentration determined in the preliminary tests, and then spraying or soaking operations are carried out. During the mobile leaching process, the leaching work should be carried out strictly in accordance with the key conditions such as the suitable pulp concentration, gold leaching material concentration and leaching time determined by the tests. It is worth noting that during the entire leaching process, the concentration of the gold leaching agent should be measured regularly. Once a decrease in concentration is detected, the gold leaching agent should be added in a timely manner to ensure the continuous and efficient progress of the leaching reaction. In addition, due to the differences in ore composition and pH value, the dosage of the gold leaching agent must be determined according to the actual dosage of the ore and the suitable concentration obtained from the ore sample experiments, so as to achieve accurate use and avoid waste and insufficiency.

Remarkable Characteristics of Environmental-friendly Gold Leaching Agent

Outstanding Safety and Environmental Friendliness

One of the biggest advantages of the environmental-friendly gold leaching agent is its safety and non-toxicity. Compared with highly toxic sodium cyanide, it fundamentally reduces the environmental protection costs of gold processing plants, avoids the high environmental protection investment and potential environmental risks brought by the use of highly toxic substances, and truly achieves the goal of green mining.

High-efficiency and Rapid Leaching Characteristics

It has an extremely fast washing speed. Usually, the leaching rate can reach more than 90% within 6 - 8 hours. This characteristic greatly improves production efficiency, and the leaching operation becomes more convenient. More prominently, it can complete the leaching operation at room temperature and within a wide range of average pH values from 3 - 11. with relatively low requirements for environmental conditions and strong adaptability.

Less Affected by Ore Properties

This gold leaching agent has low sensitivity to associated metals, and the leaching process has nothing to do with oxygen in the atmosphere. This means that the production of leachate is less affected by ore properties, and the leachate can be recycled, which not only reduces production costs but also reduces environmental pollution.

Good Chemical Stability and Low Drug Consumption

The environmental-friendly gold leaching agent has good chemical stability and low drug consumption during use. This not only reduces the production costs of enterprises but also reduces the operational complexity brought about by frequent addition of agents.

Sufficient Raw Materials and Stable Prices

The raw materials for drug production are sufficient, which provides a solid material basis for its large-scale production. At the same time, the price is stable, giving gold processing enterprises an advantage in cost control without having to worry about the cost pressure brought about by fluctuations in raw material prices.

Product Diversity

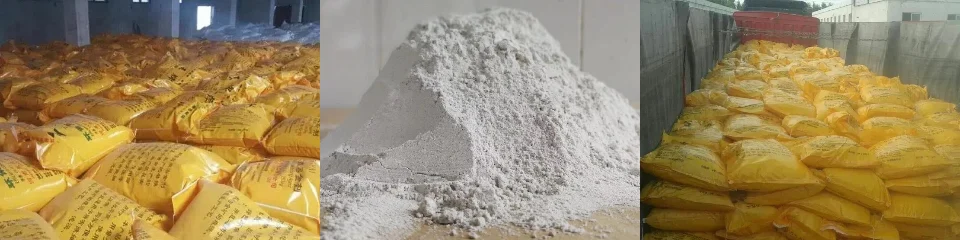

There is a complete variety of gold leaching agents, and suitable gold leaching agents can be selected according to the characteristics of different ores. This personalized choice can give full play to the effectiveness of the gold leaching agent, increase the gold extraction rate, and meet the diverse needs of different gold mining enterprises.

Omnidirectional Advantages

The environmental-friendly gold leaching agent combines many advantages such as environmental protection, non-toxicity, strong gold dissolution ability, good stability, fast recovery, low consumption, low cost, and convenient storage and transportation. It truly transforms the concept of "green mining and environmental-friendly gold extraction" into a practical and feasible production method.

The environmental-friendly gold leaching agent, with its unique extraction method and remarkable characteristics, has brought revolutionary changes to the gold ore extraction industry. It not only solves the environmental problems brought by traditional sodium cyanide but also shows great potential in improving production efficiency and reducing costs. With the continuous improvement and promotion of technology, the environmental-friendly gold leaching agent is expected to be more widely applied in the field of gold ore extraction, leading the industry to develop in a green and sustainable direction.

- Random article

- Popular articles

- Popular comments

- Sand gold beneficiation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Titanium Ore Processing: Magnetic Separation and Flotation

- Titanium Ore Processing: Magnetic Separation, Gravity Separation, Flotation

- Titanium Ore Processing: Gravity, Magnetic, Flotation, Electric Separation

- Mica Ore Treatment: Magnetic Separation, Gravity, Flotation

Leave a message with your needs or comments

Add comment: