The partial mixed flotation method for copper ore is a flotation process that uses two rounds of mixed flotation based on the properties of the ore, aiming to improve the comprehensive resource recovery level and reduce the dosage of reagents.

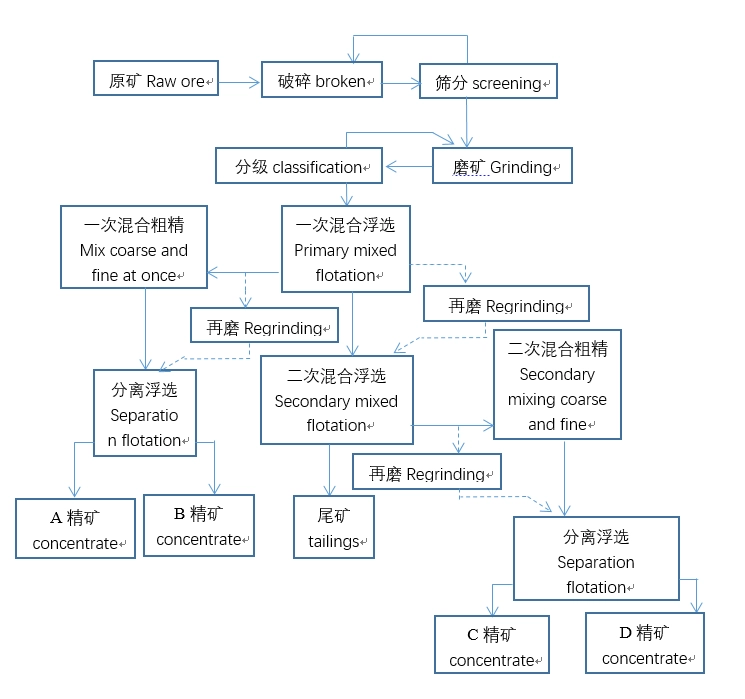

Partial mixed flotation process flow of copper ore

1.Ore crushing:Crush the copper ore to an appropriate particle size for subsequent flotation operations.

2.First mixed flotation:Based on the characteristics of the ore, select appropriate flotation reagents and conditions to enrich some useful minerals with similar floatability into the mixed coarse concentrate.

3.Second mixed flotation:Re grinding or using other chemical processes on the tailings from the first mixed flotation to enrich the remaining useful minerals into another mixed coarse concentrate.

Characteristics of partial mixed flotation process for copper ore

1.Fully considering the floatability characteristics of the ore itself is beneficial for improving the comprehensive resource recovery level, reducing the dosage of reagents, and lowering production costs.

2.Through two rounds of mixed flotation, different grades of concentrates can be effectively separated, improving the economic benefits of the mine.

3.The flotation process is stable and easy to operate, which is beneficial for improving flotation efficiency.

Partial mixed flotation of copper ore is an effective flotation process for treating copper ore. It can use a two-stage mixed flotation method based on the properties of the ore to enrich useful minerals with similar floatability into the mixed coarse concentrate, and then separate the mixed coarse concentrate to obtain multiple concentrate products. This method is beneficial for improving the comprehensive resource recovery level, reducing production costs, and improving the economic benefits of mines.

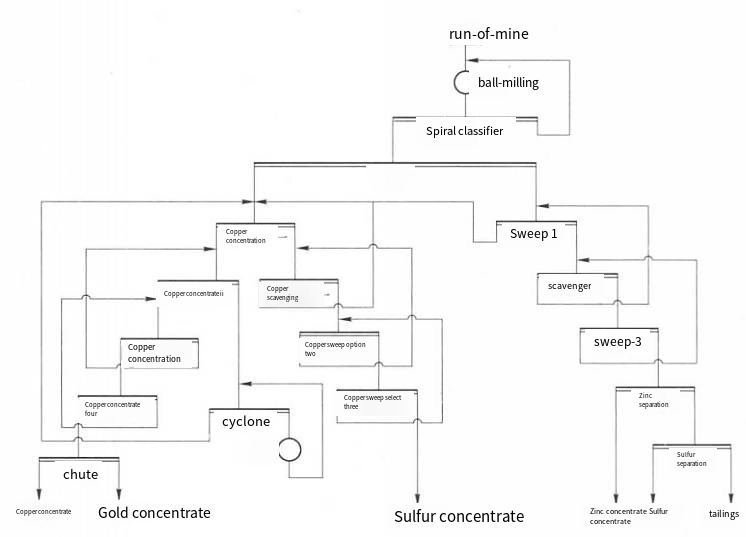

Typical beneficiation plant

Fushun Hongtoushan Copper Mine Dressing Plant: The main useful minerals in the ore are pyrite, chalcopyrite, magnetite, sphalerite, and cubic copper ore; The mineral composition of ore is relatively simple, but its structure is complex. The partial mixed flotation process is adopted. Firstly, a portion of easily floatable pyrite is mixed with chalcopyrite to obtain a mixed coarse concentrate. Then, zinc and sulfur separation operations are carried out on the mixed flotation tailings. The mixed coarse concentrate is separated, floated, and re selected to obtain copper concentrate, gold concentrate, and sulfur concentrate, respectively. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Tin ore flotation processing technology

- Hg-ore gravity separation process

- Lithium ore combined beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Titanium Ore Processing: Gravity, Magnetic, Flotation, Electric Separation

- Barite Magnetic Separation Process for Efficient Purification

Leave a message with your needs or comments

2024-07-12 09:01:23 Reply

Add comment: