The flotation method has two different functions in tin ore beneficiation. One is used to treat fine-grained tailings and re selected fine mud in the tin ore beneficiation process; The second method is used to separate sulfides from cassiterite.

Flotation process is used to treat fine-grained tailings and gravity selected fine mud

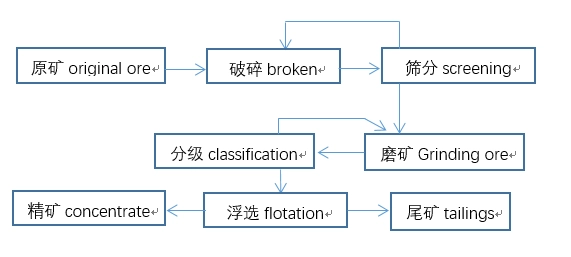

1.Process flow:

Tailings Treatment:Firstly, the tailings in the cassiterite beneficiation process are finely graded to separate the fine-grained tailings from the re selected fine mud.

Preparation before flotation:Necessary pre-treatment of fine-grained tailings and re selected fine mud, such as stirring and slurry mixing, is carried out to improve flotation efficiency.

Flotation:Using a flotation machine (such as a mechanical stirring flotation machine or a jet flotation machine) for flotation operations, adding suitable flotation agents such as collectors and foaming agents to achieve the recovery of cassiterite.

Selection and Concentration:Through multiple flotation and selection, the recovery rate of cassiterite is improved, and finally the flotation concentrate is concentrated and dried.

2.Technological advantages:

Resource recovery:Through flotation technology, it is possible to effectively recover cassiterite from fine-grained tailings and re selected fine mud, improving resource utilization efficiency.

Improving Economic Benefits:Recycling fine-grained cassiterite can reduce resource waste and improve the economic benefits of beneficiation plants.

Environmentally friendly:Reduce tailings stacking and environmental pollution, in line with the development concept of green environmental protection.

Flotation process for separating sulfides in cassiterite

1.Process flow:

Ore crushing and grinding:First, crush and grind the cassiterite ore to the appropriate particle size for subsequent flotation operations.

Sulfide flotation:Using a flotation machine to perform sulfide flotation operations, adding specific flotation agents such as xanthate and black medicine to achieve selectivity of sulfides.

Cassiterite flotation:After sulfide flotation, the flotation of cassiterite usually requires the use of different reagents and conditions to achieve separation of cassiterite from other minerals.

Concentrate Treatment:Necessary selection and concentration of cassiterite flotation concentrate to improve tin recovery and purity.

2.Technological advantages:

Improving the Quality of Tin Concentrate:The flotation process can effectively separate sulfides in tin ore and improve the quality of tin concentrate.

Reduce the impact of impurities:Sorting sulfides helps to reduce the content of sulfides in tin concentrates and reduce the impact of impurities in subsequent smelting processes.

Optimize resource utilization:Through flotation technology, cassiterite resources can be more effectively utilized, reducing resource waste.

In summary, the application of flotation technology in tin ore beneficiation is of great significance. It can not only improve the recovery rate of resources and the economic benefits of beneficiation plants, but also reduce environmental pollution and promote sustainable development.

Typical beneficiation plant

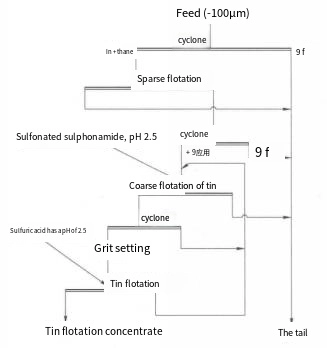

Korkuili beneficiation plant: The ore is cassiterite sulfide ore, locally oxidized; The main minerals are cassiterite, sphalerite, pyrite, pyrrhotite, etc. The main vein mineral is quartz; Re select fine mud and fine-grained tailings for flotation.

- Random article

- Popular articles

- Popular comments

- Hg-ore flotation process

- Iron Ore Roasting and Magnetic Separation Process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore positive flotation process

- Uranium Ore Radioactive Treatment Process

- Chromium Ore Gravity Separation and Flotation Process

- Combined Process for Manganese Ore Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: