The lithium ore positive flotation process is a flotation method specifically designed for extracting lithium from lithium ores. This process separates lithium minerals from gangue minerals by adding alkaline slurry of sodium hydroxide or sodium carbonate after finely grinding lithium ore.

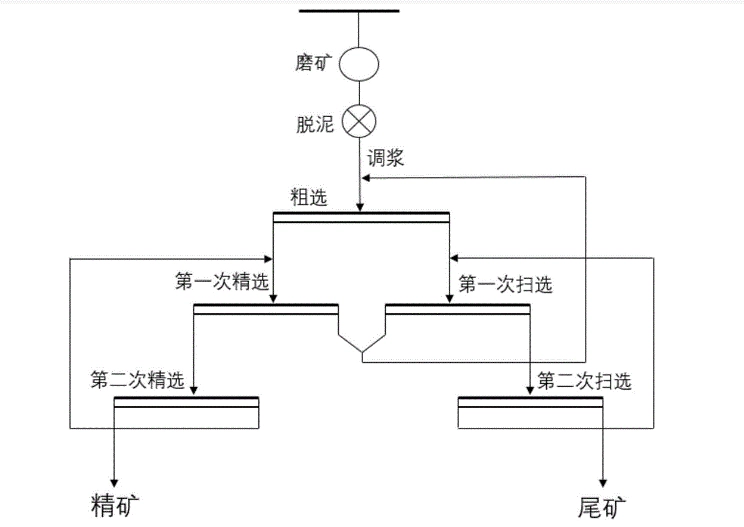

process flow

1.Fine grinding:First, finely grind the lithium ore for flotation treatment. During the fine grinding process, it is necessary to avoid over grinding as much as possible to prevent the occurrence of mud formation.

2.Alkaline slurry treatment:The finely ground lithium ore is added to the alkaline slurry of sodium hydroxide or sodium carbonate. Alkaline media helps to improve the floatability of lithium minerals.

3.High concentration, strong stirring, and multiple scrubbing for desliming:In an alkaline medium, lithium minerals are separated from gangue minerals through high concentration, strong stirring, and multiple scrubbing for desliming. This step helps to remove mud impurities and improve the quality of lithium concentrate.

4.Collector addition:After desliming, add fatty acids (such as oleic acid) and their soap salts as collectors. These collectors can interact with the surface of lithium minerals, causing them to float upwards.

5. Flotation:Flotation treatment is carried out using a flotation machine to separate lithium minerals from other minerals. During flotation, lithium minerals will form foam with collectors, and then collect lithium minerals in foam layer through foam separator.

6.Selection: The lithium mineral after flotation undergoes three rounds of selection to further improve the grade and recovery rate of lithium. After selection, spodumene concentrate with a grade greater than 5% Li2O and a recovery rate of 70% to 75% can be obtained.

7.No need to add inhibitors:Compared with other flotation processes, the lithium ore positive flotation process does not require the addition of inhibitors, reduces the use of chemical reagents, lowers production costs, and is more environmentally friendly.

Technological advantages

Efficient Extraction: The lithium ore positive flotation process can efficiently extract lithium from lithium ore, improving the grade and recovery rate of lithium.

No need to add inhibitors:This process does not require the addition of inhibitors, reduces the use of chemical reagents, lowers production costs, and is more environmentally friendly.

Easy to operate:The process flow is relatively simple, with fewer operating steps and lower technical requirements for operators.

Strong adaptability:This process is suitable for the extraction of various lithium ores and has strong adaptability.

The lithium ore positive flotation process is an efficient, environmentally friendly, and easy to operate lithium extraction method, suitable for large-scale development and utilization of lithium ores.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron ore positive flotation process

- Gold Mine Heap Leaching: Optimal Process

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Uranium Ore Radioactive Treatment Process

- Zirconium Ore Separation: Gravity and Magnetic Methods

Leave a message with your needs or comments

Add comment: