The heavy medium beneficiation process is a physical beneficiation method based on mineral density differences for separation, suitable for spodumene ores with relatively coarse crystalline particle size. In spodumene ore, the relative density of spodumene is about 3.2. which differs from the density of associated vein minerals such as quartz and feldspar, but usually does not exceed 0.2-0.5g/cm ³。

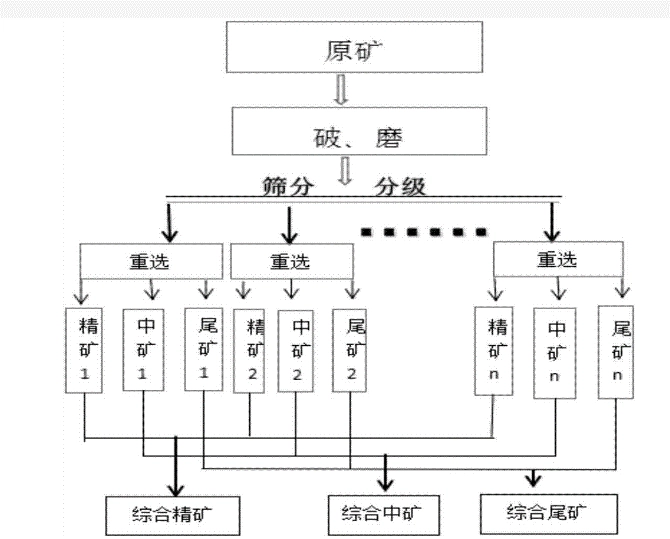

process flow

1.Ore preparation:Firstly, the spodumene ore is washed and deslimed to remove mud impurities and small particles from the ore.

2.Heavy medium preparation:Preparation of heavy medium, usually using magnetite or barite as the heavy medium, with a density higher than spodumene but lower than gangue minerals.

3.Mixing: Mix the lithium ore after washing and desliming with heavy medium to ensure that there are enough heavy medium particles in the slurry to distinguish spodumene and gangue minerals.

4.Pressure feeding:Feed the mixed slurry into the heavy medium cyclone at a pressure of 0.05-0.20MPa. The rotational effect and high pressure of the cyclone help to separate minerals based on their density differences.

5.Selection:In a heavy medium cyclone, high-density spodumene floats up to the center of the cyclone as a heavy mineral product, while low-density gangue minerals sink to the bottom of the cyclone as light products.

6.Demediation Screen Demediation:Heavy products (lithium concentrate) and light products (tailings) are respectively screened through the Demediation Screen to remove residual heavy medium particles.

7.Lithium concentrate and tailings:After being separated by a demedium sieve, the heavy product becomes lithium concentrate, while the light product becomes tailings. Tailings mainly contain vein minerals such as quartz, feldspar, and biotite.

Technological advantages

Efficient Separation:The heavy medium beneficiation process can efficiently separate spodumene based on differences in mineral density, improving the recovery rate of spodumene.

Strong adaptability:This process is suitable for spodumene ores with relatively coarse crystalline particle size and has strong adaptability to the ore.

Cost saving:Compared with chemical beneficiation methods, the heavy medium beneficiation process saves the use of chemical reagents and reduces production costs.

Environmentally friendly:Due to the absence of chemical reagents, this process has minimal impact on the environment.

Easy to operate:The process flow is relatively simple, the operation is convenient, and the technical requirements for operators are relatively low.

The heavy medium beneficiation process is an efficient, economical, and environmentally friendly method for separating spodumene ores, suitable for separating spodumene ores with relatively coarse crystalline particle size. Through this process, high-grade lithium concentrate can be obtained while reducing its impact on the environment.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold Mine Gravity Beneficiation Process

- Sand gold beneficiation process

- Lead-zinc Ore Asynchronous Flotation Process

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Chromite Gravity and Magnetic Separation Process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Understanding the Manganese Ore Flotation Process

Leave a message with your needs or comments

Add comment: