The asynchronous flotation process of lead-zinc ore is a method of separating the same mineral into two steps for flotation recovery, mainly including asynchronous mixed flotation and asynchronous priority flotation.

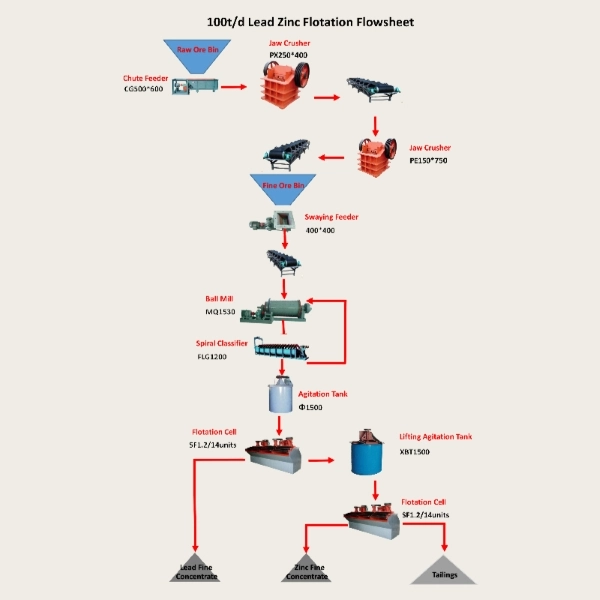

Asynchronous flotation process flow of lead-zinc ore

1.Asynchronous mixed flotation:Asynchronous mixed flotation refers to the process of mixing lead sulfide ore and oxide ore together, first performing rough selection to float most of the minerals, and then selecting to further enrich useful minerals. The advantage of this method is to maintain a high recovery rate while reducing the dosage of chemicals. Because in the rough selection stage, the agent can act on both sulfide and oxidized ores simultaneously, thereby reducing the amount of agent used. In the selection stage, useful minerals have already been enriched together, so the agent can act more targeted on these minerals, thereby improving the recovery rate.

2.Asynchronous priority flotation:Asynchronous priority flotation refers to the separate flotation recovery of lead sulfide and oxide ores. First, the sulfide ore is recovered by flotation, and then the oxidized ore is recovered by flotation. The advantage of this method is that it is conducive to achieving targeted recovery of oxidized and sulfide ores. Due to the different properties of sulfide ore and oxide ore, different flotation reagents and conditions need to be used. Through asynchronous priority flotation, targeted selection of reagents and conditions can be made to improve flotation efficiency and recovery rate.

Characteristics of asynchronous flotation process for lead-zinc ore

In the asynchronous mixed flotation stage, various minerals in lead zinc ore are simultaneously flotation, without distinguishing the order. This method can provide opportunities for various minerals to be flotation simultaneously, thereby improving flotation efficiency.

In the asynchronous priority flotation stage, a certain mineral (usually a high-value mineral) in lead-zinc ore is first flotation out, and then other minerals are flotation. This method can enable more efficient recovery of valuable minerals.

Asynchronous mixed flotation can maintain a high recovery rate while reducing the dosage of reagents, while asynchronous priority flotation is beneficial for achieving targeted recovery of oxidized and sulfide ores.

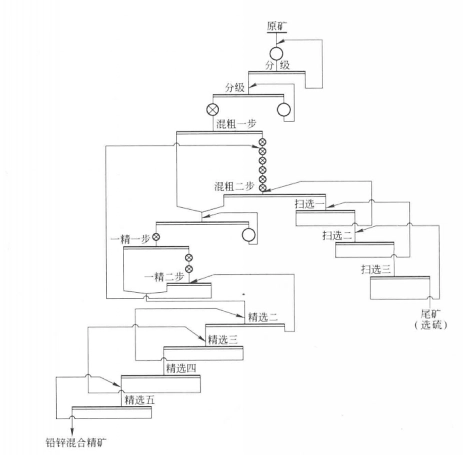

Typical beneficiation plant

Fankou Lead Zinc Mine Dressing Plant: The original ore of this mine is a fine-grained, uneven and complex embedded lead zinc iron high sulfur composite sulfide ore. The main useful minerals are pyrite, sphalerite, and galena. The asynchronous mixed flotation process is adopted to ultimately produce lead zinc mixed concentrate products. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Hg-ore gravity separation process

- Carbon leaching beneficiation process for gold mines

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Chromite Gravity and Magnetic Separation Process

- Basic techniques for antimony ore flotation processing

- Molybdenite Grinding and Separation Process

- Rutile Processing: Gravity, Magnetic, Flotation, Electric Separation

Leave a message with your needs or comments

Add comment: