The mixed separation flotation process of lead zinc ore is a method for treating polymetallic ores containing two or more useful components. The main purpose of this method is to enrich different minerals into different products through flotation, thereby achieving comprehensive recovery of useful minerals.

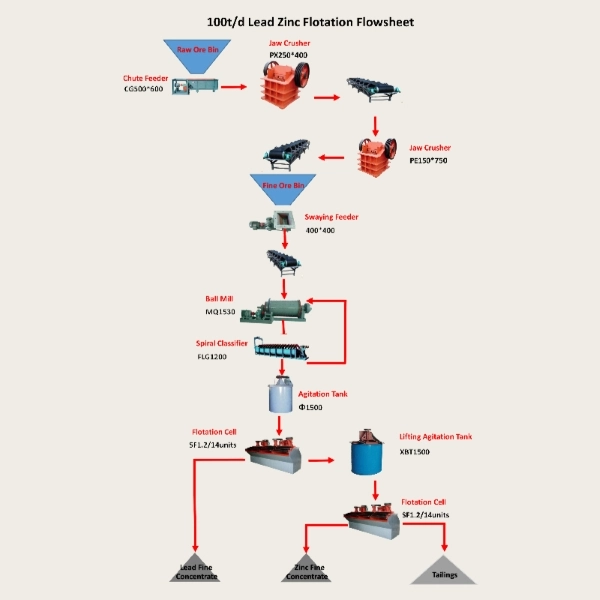

Process flow of mixed and separated flotation of lead zinc ore

1.Mineral preparation:Crushing and grinding the ore to achieve a certain fineness is beneficial for the subsequent beneficiation process

2.Mixed flotation:Adding mixed flotation agents such as ethylenediamine and xanthate to the slurry enables flotation of different minerals. By one or more floatations, useful minerals are enriched together to obtain a mixed concentrate.

3.Separation flotation:Further flotation separation is carried out on the mixed concentrate to separate different minerals. The commonly used separation flotation methods include zinc suppression and lead flotation, as well as activated zinc selection. By flotation once or multiple times, lead concentrate with high lead content and zinc concentrate with high zinc content can be obtained.

Characteristics of mixed and separated flotation process for lead-zinc ore

1.Improve resource utilization:By combining flotation and separation flotation, useful minerals in ores can be effectively recovered and resource utilization can be improved.

2.lower production cost:Throwing away a large amount of tailings in advance at coarser grinding fineness can reduce equipment and investment in grinding and flotation, and lower production costs.

3.Reduce environmental pollution:Reducing equipment and investment in grinding and flotation can reduce tailings and chemical pollution, as well as environmental pollution.

The mixed separation flotation process of lead zinc ore is an effective method for treating polymetallic ores, which can achieve comprehensive recovery of useful minerals, improve resource utilization, reduce production costs, and reduce environmental pollution. This method has the advantages of simple process, easy control of chemical conditions, and stable indicators, and is suitable for various types of polymetallic ores.

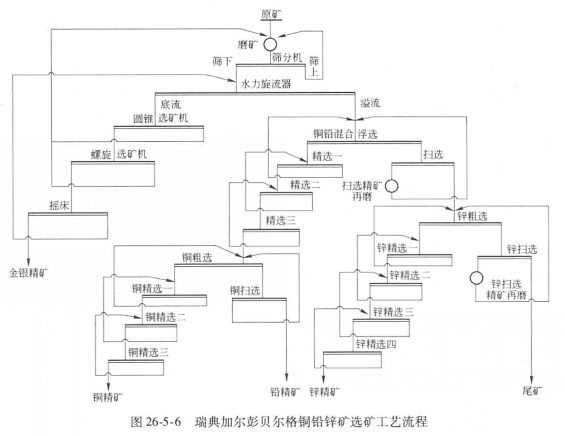

Typical beneficiation plant

Galpenberg Copper Lead Zinc Concentrator in Sweden: The Galpenberg Copper Lead Zinc Mine is located in central Sweden, with the main useful minerals being chalcopyrite, galena, sphalerite, and a small amount of pyrite. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Tin ore gravity+flotation process

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Lithium Ore Processing: Gravity Separation and Flotation

- Efficient Tantalum-Niobium Ore Separation: Gravity vs. Flotation

- Efficient Flotation Process for Sulfide Fluorspar Ore

- Mica Ore Treatment: Magnetic Separation, Gravity, Flotation

Leave a message with your needs or comments

Add comment: