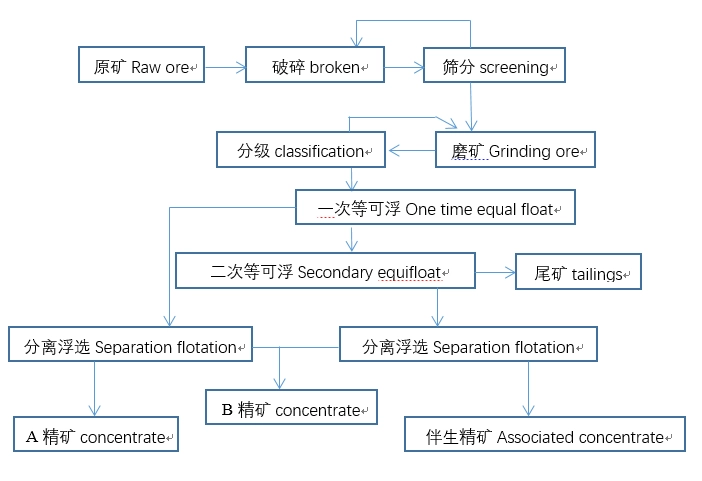

The floatability flotation process of lead-zinc ore is a method of flotation based on the natural floatability characteristics of the ore. The main purpose of this method is to flotation minerals with similar floatability into the same mixed concentrate, and then separate the mixed concentrate to obtain different concentrate products.

Floatability flotation process of lead zinc ore

1.Raw ore crushing:Grinding the lead zinc ore to achieve appropriate fineness usually requires individual mineral dissociation, but not excessive grinding.

2.Flotation preparation:Add an appropriate amount of flotation agents, such as collectors and foaming agents, to the ground slurry to adjust its flotation properties.

3.Rough selection:The prepared pulp is injected into the flotation machine, and the valuable minerals are separated from gangue minerals through stirring and aeration to form a rough foam.

4.Mixed concentrate treatment:The roughing foam is collected, which represents the mixed concentrate. The mixed concentrate contains lead zinc minerals with similar floatability.

5.Separate concentrate:Further processing of mixed concentrates, such as re selection or reverse flotation, to separate different lead zinc concentrate products

6.Tailings treatment:Treat the tailings generated during the flotation process, including solid-liquid separation and waste liquid treatment, to meet environmental protection requirements.

Characteristics of floatability flotation process for lead-zinc ore

1.Utilizing natural floatability:The floatability flotation process fully utilizes the differences in natural floatability of different minerals in the ore, simplifying the flotation process.

2.Simplify the process:By flotation minerals with similar floatability into mixed concentrates and then separating them, the traditional complex flotation process is simplified.

3.Improve efficiency:The floatability flotation process improves flotation efficiency because similar floatable minerals can be simultaneously floated out in one stage.

4.flexibility:According to the specific properties of the ore, the floatability flotation process can be adjusted appropriately to adapt to different mineral combinations and floatability conditions.

5.Saving Medication:According to the natural floatability characteristics of ore, flotation can fully utilize the flotation performance of the ore itself, thereby reducing the dosage of reagents and lowering production costs.

The float flotation process for lead-zinc ore is an effective beneficiation method that can fully utilize the natural floatability of the ore, save reagents, improve resource utilization, and reduce environmental pollution. This method has the advantages of simple process, easy control of chemical conditions, and stable indicators, and is suitable for various types of lead zinc ores.

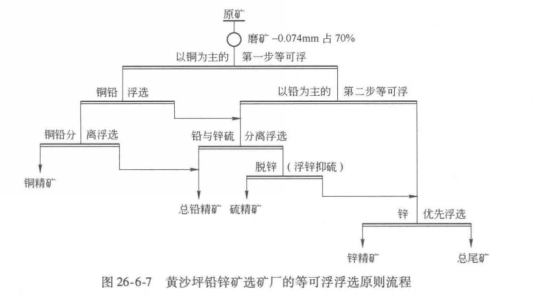

Typical beneficiation plant

Huangshaping Lead Zinc Mineral Processing Plant: The plant is located in Guiyang County, Hunan Province, China. The main useful minerals in the ore are galena, sphalerite, pyrite, chalcopyrite, etc; Using the equal floatability process, copper minerals and some lead minerals are first mixed and floated to obtain a copper lead mixed concentrate. The tailings are subjected to secondary equal floatability to obtain a lead zinc sulfur mixed concentrate. Then, zinc selection operations are carried out, and the two mixed concentrates are separated and floated separately to obtain copper concentrate, lead concentrate, zinc concentrate, and sulfur concentrate, respectively. The specific principle process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity processing technology

- Gold selection process using resin slurry method

- Carbon leaching beneficiation process for gold mines

- Floatability flotation process for lead-zinc ore

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Lithium ore reverse flotation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

Leave a message with your needs or comments

Add comment: