At present, the main tin mines that have been mined in the world include native tin and sand tin; Tin reserves are mainly concentrated in Asia and South America, with China being the world’s largest producer of tin mines; The traditional beneficiation process for tin ore is gravity separation, and flotation, selective flocculation, magnetic separation, etc. are gradually being applied; Due to the brittleness and fragility of cassiterite, a stage grinding selection process is often used.

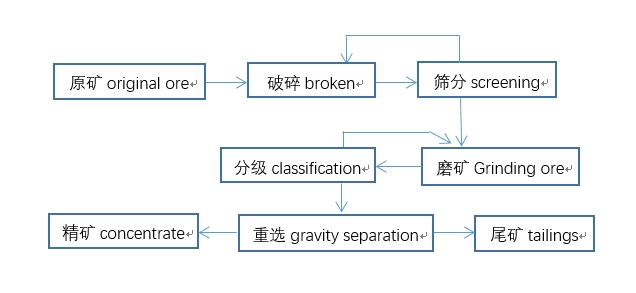

Tin ore gravity beneficiation process flow

1.Raw ore preparation:

Crushing:Crushing the raw ore to an appropriate particle size for subsequent grinding and re selection operations.

Grinding:Through multi-stage grinding, the ore is ground to a sufficiently fine particle size to increase the dissociation between cassiterite and associated minerals, creating conditions for gravity separation operations.

2.Graded Desliming:

Using equipment such as ore washing machines, cross flow belt chutes, and small diameter cyclones, the slurry after grinding is deslimed to remove fine slime, while controlling the selected particle size to ensure the efficiency of the re selection equipment.

3.Re select homework:

Jig:The jig separates cassiterite from coexisting minerals based on differences in ore density through the action of water flow and mechanical force. Jigging machines have advantages such as high processing capacity, high recovery rate, and low energy consumption.

Shaker:Shaker uses the shaking of the bed surface and the action of water flow to finely sort the ore, suitable for processing finer grained cassiterite ore. Shaker has the characteristics of high sorting accuracy and high recovery rate.

4.Tailings treatment :

The tailings after re selection are further processed, such as concentration and drying, to reduce resource waste and environmental pollution.

Technological advantages

1.Early Separation and Recovery:The design of a multi-stage grinding and selection process allows cassiterite to dissociate from coexisting minerals in the early stages, achieving early recovery and reducing resource waste.

2.Avoid over crushing :Through graded desliming and appropriate grinding fineness control, avoid over crushing caused by unevenly embedded cassiterite, and improve the recovery rate of cassiterite.

3.Efficient and energy-saving:Equipment such as jigs and shakers have high processing capacity and sorting efficiency, which can achieve large-scale cassiterite re selection operations with low energy consumption.

4.Environmental Protection and Energy Conservation:Compared with other physical beneficiation methods, the re selection process has a relatively small impact on the environment and can effectively utilize resources, meeting the requirements of green and sustainable development.

5.Strong adaptability:The re selection process can adapt to different properties of cassiterite ores, and can still achieve effective separation and recovery in cases of uneven distribution of cassiterite particles and complex coexisting minerals in the ore.

Through the above process flow and advantages, the re selection of cassiterite has become a very important beneficiation method in cassiterite mining. It can not only improve the recovery rate of cassiterite, but also achieve rational utilization of resources and environmental protection.

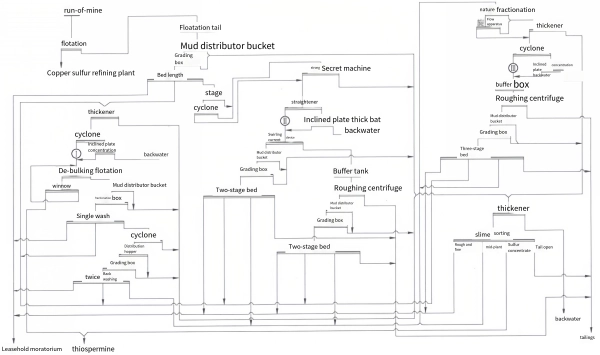

Typical beneficiation plant

Yunxi Datun Mineral Processing Branch: The ore composition is relatively complex, and the main minerals include magnetite, pyrite, arsenopyrite, chalcopyrite, quartz, feldspar, tourmaline, etc; The main useful minerals recovered are chalcopyrite and cassiterite. The process of sand ore re selection is as follows:

- Random article

- Popular articles

- Popular comments

- Gold Mine Heap Leaching: Optimal Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Prioritized Flotation Process for Lead-zinc Ore

- Branch serial flow flotation process for lead-zinc ore

- Nickel Ore Mixing and Separation Flotation Process

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Lithium ore positive flotation process

Leave a message with your needs or comments

Add comment: