The iron ore joint beneficiation process is a beneficiation method for difficult to separate iron ore with a wide variety of iron minerals and fine embedded particle size. It combines the advantages of various beneficiation methods such as magnetic separation, gravity separation, and flotation to improve the concentrate grade and recovery rate.

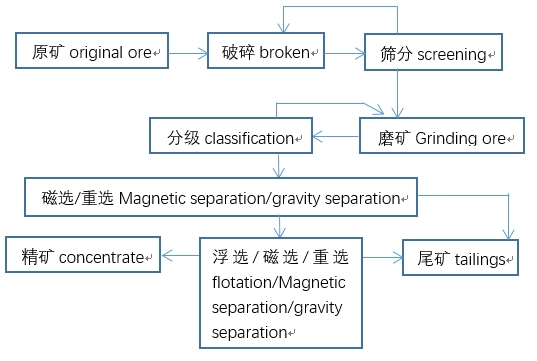

Joint beneficiation process flow of iron ore

1Pre processing:First, crush and grind the raw ore to a certain particle size, which is convenient for subsequent beneficiation operations.

2. Magnetic Separation:Using a magnetic separator to perform magnetic separation on ores and separate strong magnetic iron minerals. Magnetic separation is the first step in the combined beneficiation process, which can remove some magnetic minerals.

3.Re selection:Re select the tailings after magnetic separation, using the density difference of minerals for separation. Re selection is suitable for minerals with coarser particle size and can further remove magnetic minerals.

4.Flotation:Flotation is performed on the tailings after re selection, utilizing the differences in chemical properties on the mineral surface for separation. Flotation is suitable for fine and micro sized minerals, which can effectively improve the grade and recovery rate of the concentrate.

5.Concentrate Merger:Merge the concentrates obtained from magnetic separation, gravity separation, and flotation to obtain the final concentrate product.

6. Tailings Treatment :Treatment of tailings generated during the beneficiation process, such as grading, concentration, etc., to reduce the volume and environmental impact of tailings.

Technological advantages

1.Efficient Separation :The combined beneficiation process, through the combination of multiple beneficiation methods, can effectively separate different mineral types and particle size distributions in iron minerals, improving sorting efficiency.

2.Improve concentrate grade and recovery rate :Magnetic separation, gravity separation, and flotation each have different separation mechanisms, and combined use can fully leverage their respective advantages to improve concentrate grade and recovery rate.

3.Strong adaptability:The combined beneficiation process is suitable for various types of iron ore, especially those difficult to process through a single beneficiation method.

4.Flexible operation:The parameters of each beneficiation process can be flexibly adjusted according to the characteristics of the ore and the requirements of beneficiation, in order to achieve the best beneficiation effect.

5.Cost saving and efficiency improvement :Although the combined beneficiation process involves multiple beneficiation methods, through reasonable process design and equipment configuration, overall costs can be saved and beneficiation efficiency can be improved.

6.Environmental Protection:Compared with some traditional beneficiation methods, the combined beneficiation process reduces the use of chemical agents and has a smaller impact on the environment.

The combined beneficiation process of iron ore can effectively treat difficult to select iron ore with a wide variety of iron minerals and fine embedded particle size by combining various beneficiation methods such as magnetic separation, gravity separation, and flotation. It has the advantages of efficient sorting, improving concentrate grade and recovery rate, strong adaptability, flexible operation, cost saving, and environmental protection.

Typical beneficiation plant

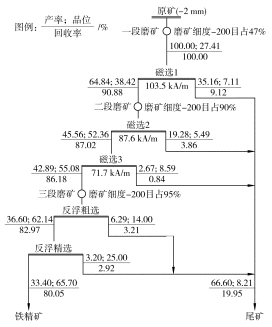

Jiajiabaozi Iron Mine of Bengang Mining: The ore is a metamorphic poor magnetite ore, with the main metal minerals being magnetite, hematite, and a small amount of siderite. The main vein minerals are quartz and biotite.

- Random article

- Popular articles

- Popular comments

- Tin ore flotation+gravity separation+magnetic separation process

- Gold Ore Carbon Slurry Beneficiation Process

- Cyanide Gold Preparation

- Uranium Ore Radioactive Treatment Process

- Chromite Gravity and Magnetic Separation Process

- Chromium Ore Gravity Separation and Flotation Process

- Rutile Processing: Gravity, Magnetic, Flotation, Electric Separation

Leave a message with your needs or comments

Add comment: