The gold heap leach method is a process for extracting gold from ore by using a leaching solution to dissolve the precious metal from the ore material. This method is particularly effective for low-grade gold ore that would not be economical to process through other, more intensive methods. Here’s a detailed look at how the gold heap leach method works:

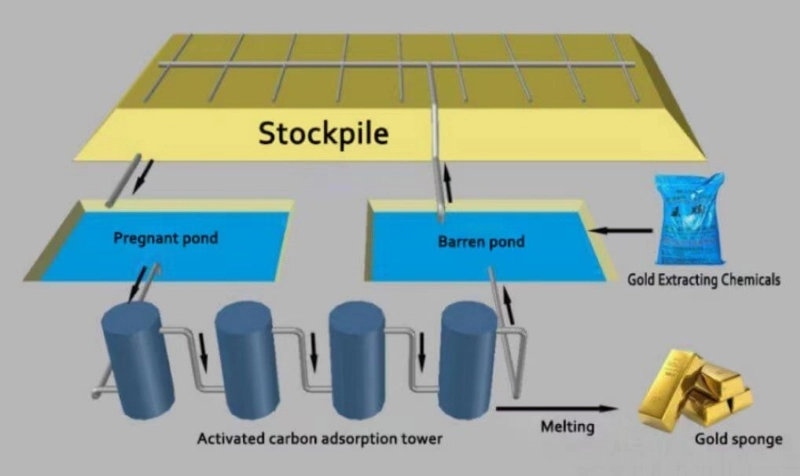

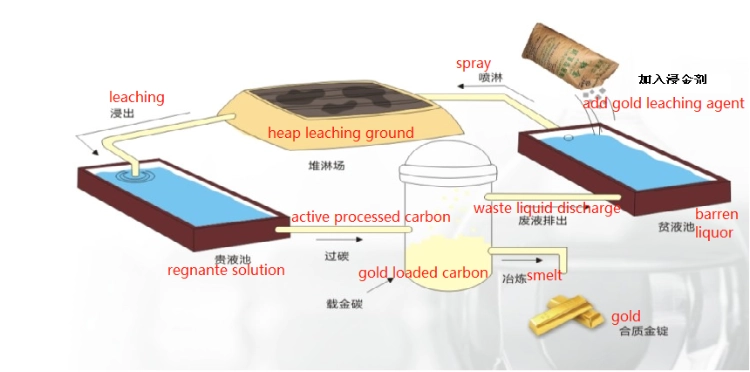

Gold heap leaching is a widely used process for recovering gold from raw ore. The process involves several key steps, including crushing and screening the raw ore to a specific size, followed by a heap leach process. In heap leach, the ore is sprayed with a cyanide leach solution, which seeps into the heap, dissolving the gold. The leachate is then collected and processed through a series of steps to recover the gold.

One of the key steps in the gold heap leaching process is the adsorption of dissolved gold onto activated carbon. After the leachate seeps through the pile and dissolves the gold, it is collected and passed through a series of tanks filled with activated carbon. The gold in the leachate is adsorbed to the carbon, leaving the solution gold-free. The gold is then stripped from the loaded carbon using a process involving zinc powder, which displaces the gold from the carbon, leaving a form that can be recycled through further processing.

Once the gold is recovered from the leachate, it is further processed to produce the final product. This typically involves analyzing the gold content to ensure its purity, and then performing electrolysis or smelting to produce the final gold product. The gold heap leach process is a complex, multi-step process that requires careful management and monitoring to ensure efficient recovery of gold from raw ore. It is a widely used and effective gold recovery method, especially for low-grade ores where traditional processing methods are not economically feasible.

Advantages of Heap Leaching

Cost-Effective: Heap leaching is generally less expensive than traditional methods, making it an attractive option for lower-grade ores.

Low Energy Consumption: The process requires less energy compared to other extraction methods.

Minimal Infrastructure: It does not require elaborate plant facilities.

Disadvantages

Time-Consuming: The leaching process can take several months to complete.

Lower Recovery Rates: Recovery rates are often lower than those achieved by conventional methods.

Environmental Concerns: The use of toxic chemicals (like cyanide for gold leaching) poses environmental risks if not managed properly.

Typical beneficiation plant

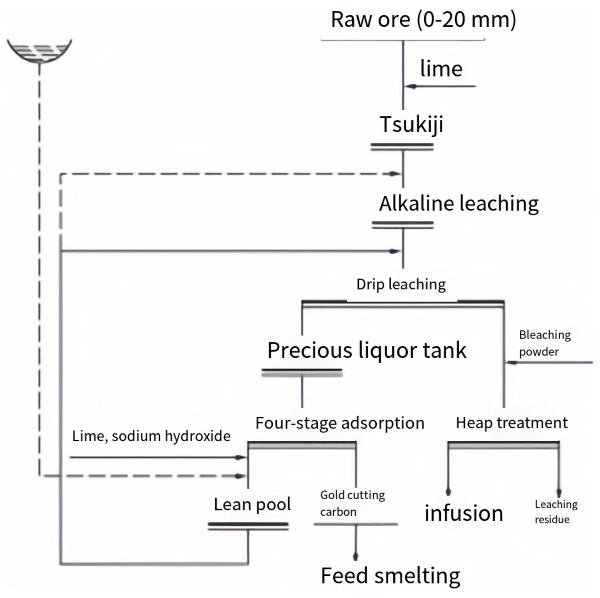

Tajikistan Gold Mine: There are few metal minerals in the ore, with gangue minerals accounting for more than 95%. The metal sulfides are mainly pyrite and arsenopyrite, and the metal oxides are mainly limonite and arsenic containing iron oxide. The gold ore is natural gold, and no other gold minerals have been found. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Effective Gravity Beneficiation for Chromium Ore

- Chromium Ore Gravity Separation and Flotation Process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Chromite Gravity, Magnetic, and Electric Separation Process

- Effective antimony ore gravity separation method

- Titanium Ore Processing: Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: