There are more than ten types of antimony containing minerals with industrial utilization value, mainly including antimonite, antimonite, yellow antimony, red antimony, brittle sulfur lead antimony, antimony, etc. The commonly used beneficiation methods for antimony ore include manual beneficiation, gravity beneficiation, flotation, etc.

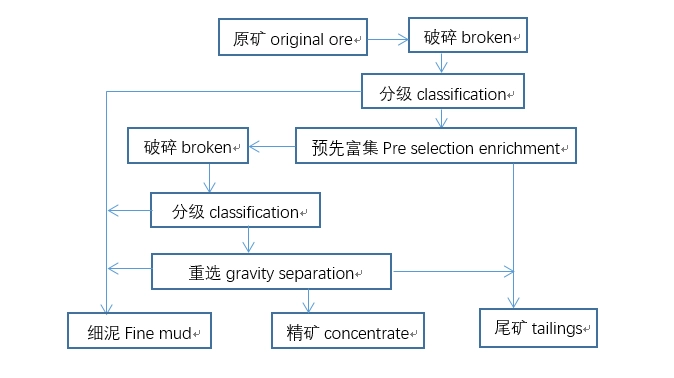

Gravity separation is suitable for most antimony ores and can also comprehensively recover some co associated metal minerals in antimony ores, making it a commonly used beneficiation method at present; The commonly used beneficiation methods in antimony ore processing include heavy medium beneficiation, jigging beneficiation, chute beneficiation, and shaking table beneficiation.

Due to the high density and coarse particle size of antimony ore, it can be separated from gangue by gravity separation. Common minerals such as antimonite, yellow antimony, red antimony, and antimony are all suitable for gravity separation. Only water antimony calcium ore has a similar sedimentation (reduction) ratio to residual gangue, making it difficult to select other minerals based on density separation. Due to the inherent characteristics of antimony ore, both single sulfide antimony ore and sulfide oxidation mixed antimony ore can be separated through gravity separation. Additionally, gravity separation can produce a large amount of qualified coarse concentrate within a coarser particle size, with less investment, making it still the preferred beneficiation method used by many beneficiation plants.

Re selection is often used as a pre selection operation for antimony flotation operations. In the face of many difficulties in flotation of antimony oxide, re selection is the main beneficiation method for antimony oxide ore. Common methods include jigging re selection, chute re selection, and shaking table re selection.

Process Flow

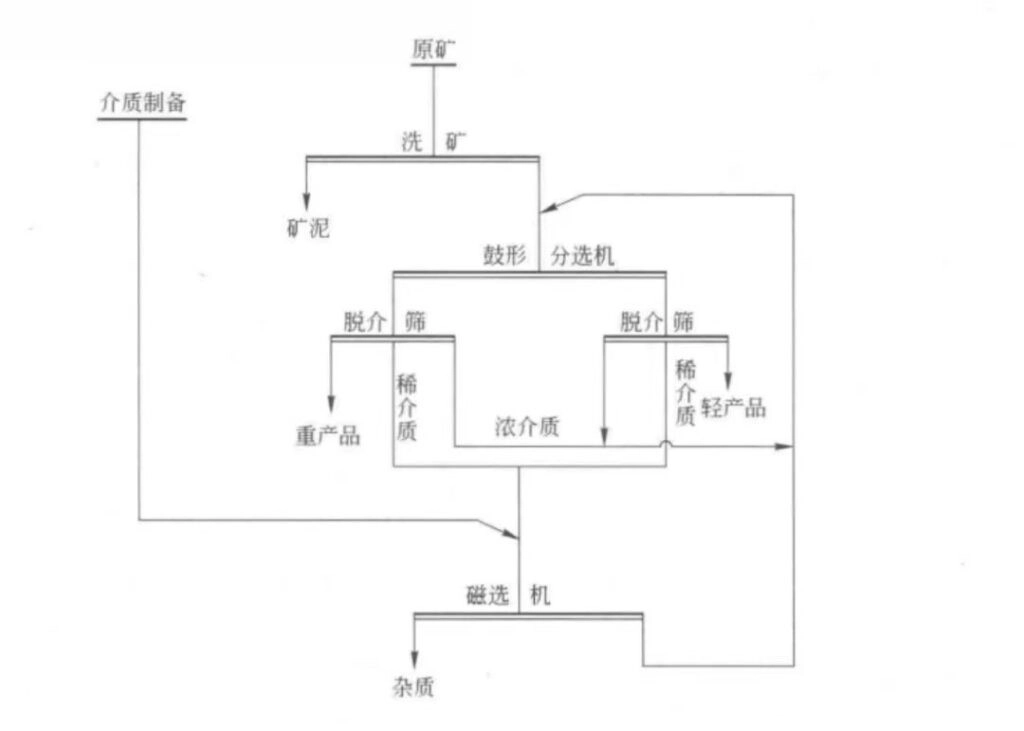

1.Heavy medium beneficiation:

Heavy media includes two types of liquids: heavy liquid and heavy suspension. The density of heavy media usually used is between the densities of light and heavy minerals in ores; In antimony ore beneficiation, heavy medium beneficiation is commonly used in pre selection operations, especially when manual beneficiation is difficult to achieve good results. Heavy medium pre selection can effectively improve the quality of flotation feed.

Typical beneficiation plant

Shanxing Antimony Mineral Processing Plant: The ore being processed is a single antimony ore, with accompanying minerals including antimony oxide and pyrite. The heavy medium separation consists of four parts, namely raw ore preparation, medium preparation, ore separation, and medium recovery and regeneration.

2.Jigging beneficiation:

Jigging beneficiation is widely used in the separation of crude materials. Currently, antimony ore jigging is mostly used in conjunction with shaking tables to treat refractory antimony ores, and can also be used as a pre recovery before flotation.

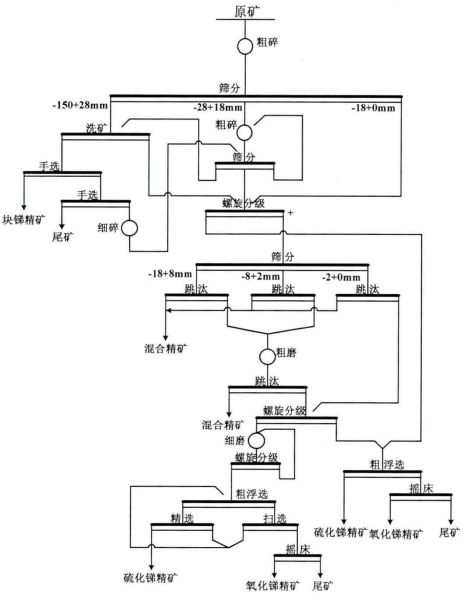

Typical beneficiation plant:

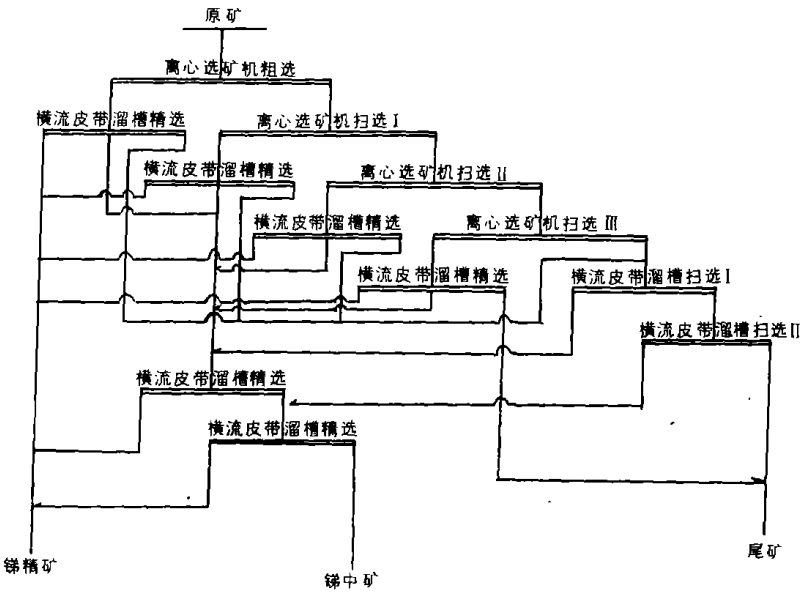

Hunan Tin Ore Dressing Plant: This mine is a mixed antimony ore, with the main useful minerals being antimonite, pyrite, antimony ochre, antimony hua, etc; Quartz is the main type of gangue, followed by calcite, limestone, and barite; The selection plant adopts a combined process of manual selection, re selection, flotation, and re selection for treatment.

3.Shaker beneficiation:

Shaker is one of the most widely used gravity separation methods for selecting fine-grained materials, especially when used to treat refractory oxidized ores. The combination of shaker and jigging can achieve indicators that cannot be achieved by a single method. The enrichment ratio of shaker is high, but the recovery rate is low and the processing capacity is small.

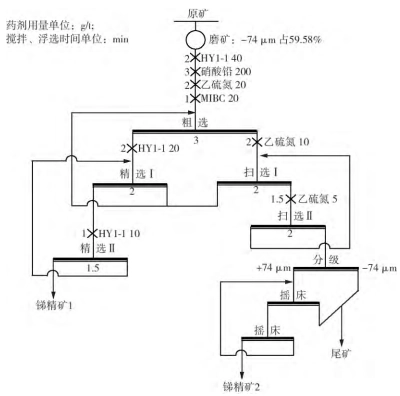

Typical beneficiation plant:

Guizhou High sulfur Low grade Antimony Mine: The ore is a mixed sulfide oxide antimony mine, with the main metal minerals being pyrite, antimonite, and antimony hua, and the main gangue minerals being quartz, mica, feldspar, etc.

4.Spiral chute beneficiation:

Processing of particles with a diameter of 2-3mm or more is called coarse grain chute, while processing particles with a diameter of 0.074-2mm is called mineral sand chute; Handle ore slurry flow channels smaller than 0.074mm; In the production of antimony ore, there are mainly centrifugal belt chutes and spiral chutes.

Typical beneficiation plant:

Mining Bureau North Selection Plant: 37 μ Materials below m are the processing objects, and the main metal minerals are antimony oxide and antimonite; Veins are mainly composed of quartz, with a small amount of mica, calcite, tourmaline, etc.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold selection process using resin slurry method

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Lithium Ore Processing: Gravity Separation and Flotation

- Efficient purification of manganese ore by magnetic separation process

- Molybdenite Grinding and Separation Process

- Copper-Molybdenum Ore Separation & Flotation Process

Leave a message with your needs or comments

Add comment: