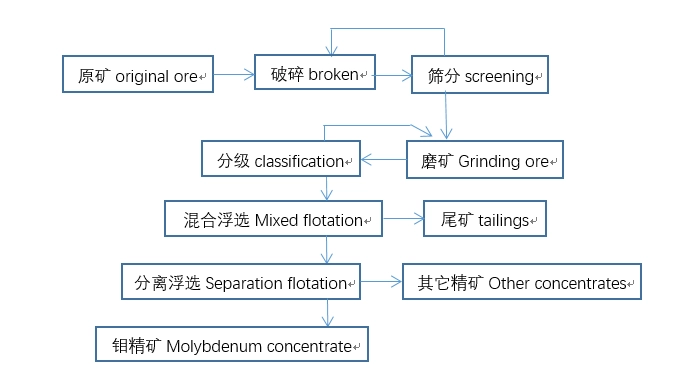

Molybdenum is rarely distributed and relatively concentrated in nature. Currently, there are more than 20 known molybdenum minerals, including molybdenite, molybdenite, molybdenite, and calcium molybdate. These four types of molybdenum minerals are currently of industrial value; Molybdenite accounts for more than 98% of the world’s mining output, and the other three are secondary oxidation minerals of molybdenite. Molybdenum ore beneficiation should prevent over grinding, and the process generally adopts a multi-stage grinding and selection process. The conventional process is: rough grinding produces coarse concentrate, sweeping tailings to recover other metals, and the coarse concentrate is further ground in 2-3 stages and selected multiple times to obtain molybdenum concentrate.

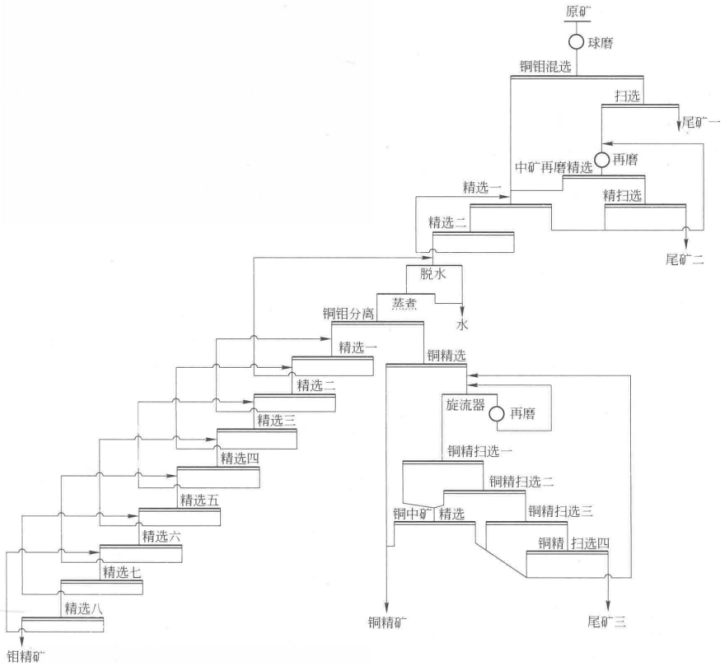

Molybdenum is often produced simultaneously with copper in nature, and copper molybdenum separation is often encountered during the production process. Currently, the commonly used method for copper molybdenum separation is to suppress copper and float molybdenum

Typical beneficiation plant

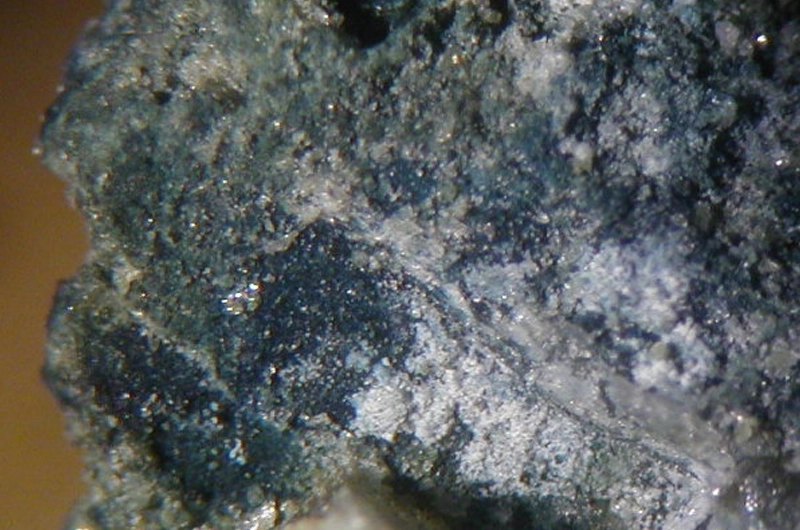

The Erdengte copper molybdenum beneficiation plant is a porphyry type copper molybdenum deposit, with copper molybdenum mineralization in the form of disseminated, vein like, and angular gravel. The metal minerals in the ore are mainly chalcopyrite, chalcopyrite, bornite, molybdenite, etc. The vein minerals are mainly quartz, feldspar, sericite, etc., and also contain a certain amount of oxidized minerals. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Gold Mine Gravity Beneficiation Process

- Lead zinc ore mixing+separation flotation process

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Uranium Ore Radioactive Treatment Process

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Manganese Ore Separation: Gravity and Magnetic Methods

- Molybdenite Grinding and Separation Process

Leave a message with your needs or comments

Add comment: