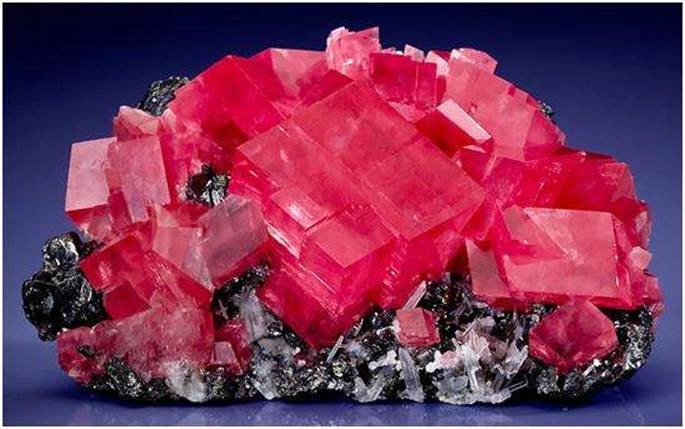

At present, more than 150 types of manganese minerals and manganese containing minerals have been discovered, with more than 20 commonly found, mainly including soft manganese ore, hard manganese ore, water manganese ore, black manganese ore, rhodochrosite, etc; The commonly used manganese ore beneficiation methods include washing, gravity separation, strong magnetic separation, flotation, pyrometallurgical enrichment, and hydrometallurgy.

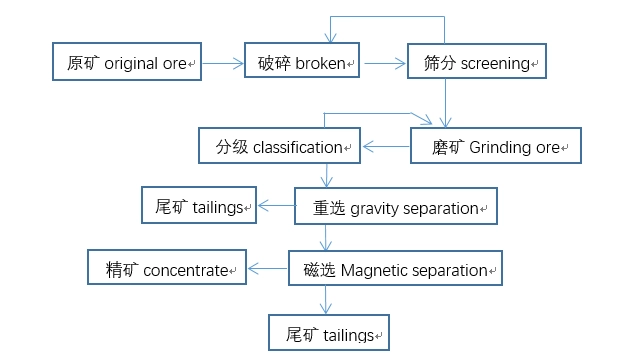

Re selection is mainly used for pre enrichment of manganese minerals, while cleaning away fine mud and other impurities in the ore. Magnetic separation is used to obtain higher grade concentrate products, and further recovery of manganese minerals can be achieved from re selected tailings to improve recovery rates.

Feed qualified manganese ore into a magnetic separator for weak magnetic separation to obtain strong magnetic manganese concentrate and weak magnetic separation tailings. The tailings are fed into the magnetic separator for strong magnetic separation to obtain strong magnetic separation tailings and concentrates. The concentrate is fed into the gravity separation equipment for separation to obtain heavy magnetic separation manganese concentrate and tailings.

Typical beneficiation plant

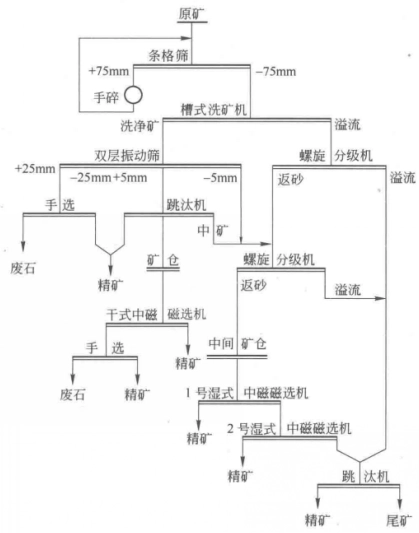

The Fujian Liancheng Manganese Ore Dressing Plant has a manganese grade of about 28%, iron content of 2.54%, phosphorus content of about 0.035%, and silicon dioxide content of about 24.36%. It belongs to low phosphorus, low sulfur, low iron, and high silicon manganese ore; The natural type of ore is mainly manganese oxide ore, and manganese minerals mainly include soft manganese ore, hard manganese ore, hidden potassium manganese ore, as well as a small amount of manganese soil, black manganese ore, etc. The vein mineral is mainly quartz, followed by kaolin, sericite, clay, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Sand gold beneficiation process

- Gravity combined beneficiation process for wolframite ore

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Lithium ore positive flotation process

- Radioactive beneficiation and flotation process for uranium ore

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

Leave a message with your needs or comments

Add comment: