At present, more than 50 types of chromium containing minerals have been discovered in nature, belonging to the categories of oxides, chromates, and silicates; Chromite is currently the only mineral in industrial production, mainly composed of iron magnesium chromite, magnesium iron chromite, aluminum iron magnesium chromite, etc. The selectivity of chromite mainly depends on its grade, embedded particle size, and gangue composition. Currently, mineral processing methods include gravity separation, magnetic separation, electrical separation, flotation, roasting magnetic separation, etc.

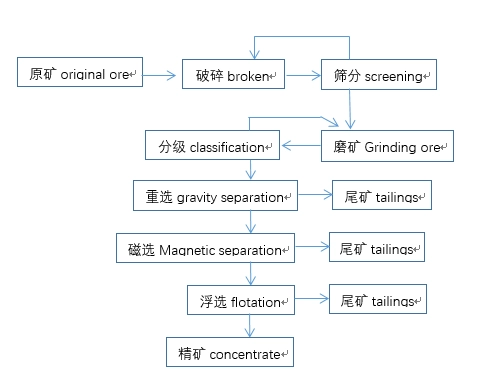

Gravity separation+magnetic separation+flotation process

After the raw ore is crushed and ground, a portion of the tailings are first discarded through gravity separation. Then, the coarse concentrate product is recovered through magnetic separation, and high-quality concentrate is obtained through flotation.

Process characteristics

High grade concentrate.

Typical beneficiation plant

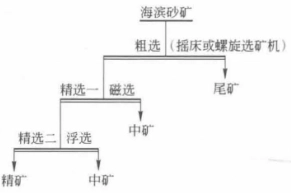

The Tiffens Mineral Processing Plant in Oregon, USA, is the largest chromium ore in the United States and is a high-speed iron deposit; The main components of the ore are quartz, olivine, ilmenite, rutile, chromite, magnetite, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity separation+flotation+gravity separation process

- Gold Mine Combined Beneficiation Process

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Lithium ore magnetic separation process

- Lithium ore heavy medium beneficiation process

- Lithium ore combined beneficiation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

Leave a message with your needs or comments

Add comment: