Joint gold selection method is a mineral processing method that combines two or more methods such as flotation, gravity separation, magnetic separation, and chemistry. This method combines the advantages of various mineral processing methods and can be used for targeted sorting, thereby obtaining better mineral processing indicators.

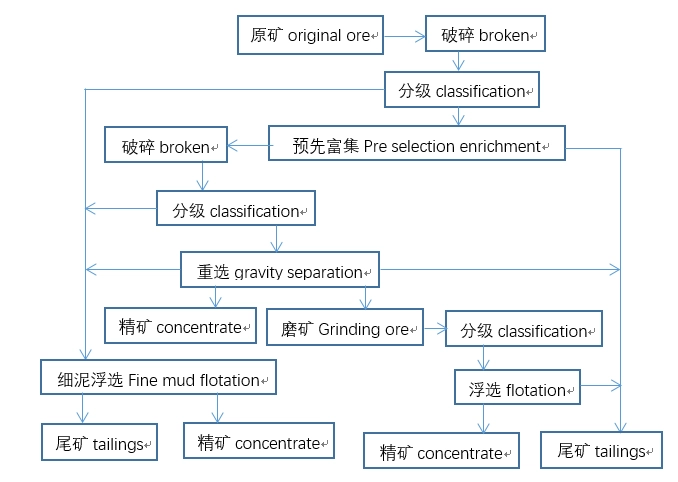

Process flow of gold mine combined beneficiation method

1.Ore crushing and grinding:Similar to a single beneficiation method, the extracted ore is first crushed and ground to achieve appropriate fineness for subsequent beneficiation processes.

2.Preprocessing:According to the characteristics and gold content of the ore, appropriate pretreatment methods can be selected, such as acid leaching, alkali leaching, etc., to improve the extractability of gold.

3.flotation:Flotation is to make use of the difference of mineral surface properties and add flotation agent to make the surface of valuable minerals in gold ore hydrophobic, so as to float up to the foam layer. Flotation can effectively separate gold from other minerals.

4.Gravity selection:Gravity sorting is a method of sorting minerals by utilizing their density differences. By the action of gravity, the denser gold minerals are separated. Re selection is suitable for the recovery of coarse-grained gold.

5.magnetic separation:Magnetic separation is a method of sorting minerals by utilizing their magnetic differences. By the action of a magnetic field, magnetic gold minerals are separated from other non-magnetic minerals.

6.Chemical beneficiation:Chemical beneficiation is the use of chemical reactions to extract gold from ores. For example, cyanide method, thiourea method, etc. Chemical beneficiation can process ores with lower gold content.

7.Combination and optimization:Based on the characteristics of the ore and the beneficiation objectives, the above methods are combined and optimized to form a combined beneficiation process suitable for specific ores.

Characteristics of the Joint Gold Selection Process

Comprehensive advantages:The combined gold selection method combines the advantages of various mineral processing methods such as flotation, gravity separation, magnetic separation, and chemistry. It can flexibly select and combine suitable methods based on the characteristics of the ore and the mineral processing objectives.

Targeted sorting:By combining different beneficiation methods, valuable minerals in gold ore can be selectively sorted, improving the gold recovery rate and beneficiation indicators.

Better indicators:The combined gold selection method can achieve efficient and accurate sorting, thereby obtaining better beneficiation indicators, such as improving gold recovery rate and reducing the content of harmful substances in tailings.

Flexibility and adaptability:The combined gold selection method has strong flexibility and adaptability, and can adjust and optimize the beneficiation process according to the changes in the ore and the requirements of the beneficiation objectives.

Joint gold selection method is an efficient, flexible, and adaptable mineral processing method, suitable for processing complex or variable ores. By combining the advantages of various beneficiation methods and conducting targeted sorting, better beneficiation indicators can be obtained. However, the application of the combined gold beneficiation method requires a deep understanding and rich practical experience of different beneficiation methods to ensure the smooth progress of the beneficiation process and the optimization of beneficiation indicators.

Typical beneficiation plant

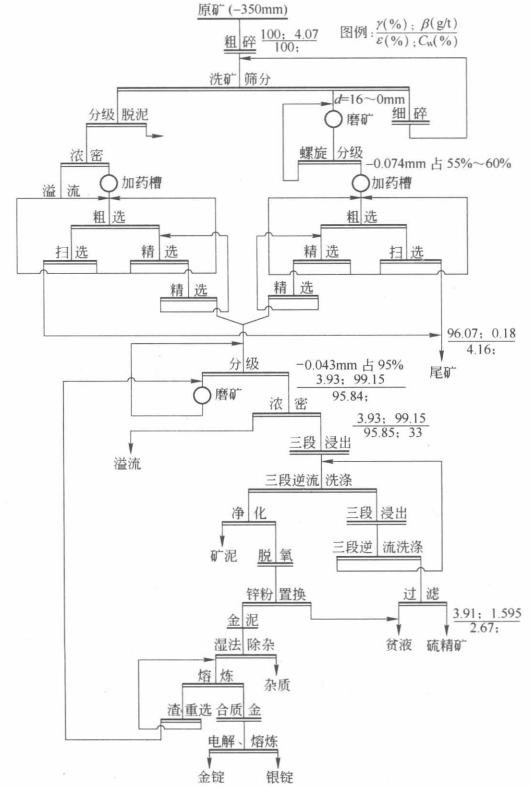

Shandong Huangjin Xincheng Gold Mine Dressing Plant: The main metal minerals in the ore are pyrite, chalcopyrite, galena, sphalerite, and silver gold, while the vein minerals are quartz, sericite, chlorite, and calcite. The specific process is as follows:

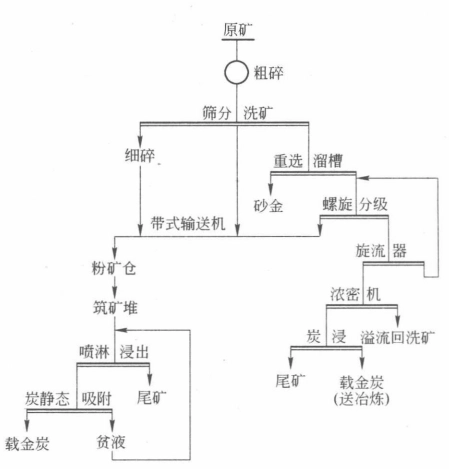

Fujian Zijinshan Gold Mine Dressing Plant: The ore is oxidized secondary gold ore, and the gangue is mainly composed of quartz, diorite, and clay minerals. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Lithium ore magnetic separation process

- Lithium ore combined beneficiation process

- Chromium Ore Gravity Separation and Flotation Process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Manganese ore washing to achieve the best results

- Combined Process for Manganese Ore Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: