Lithium ore magnetic separation process is a process used to remove iron impurities from lithium concentrate or to separate weakly magnetic iron lithium mica. This process is mainly based on the lithium pyroxene concentrate obtained by flotation, and removes iron containing impurity minerals through strong magnetic separation to obtain low iron lithium pyroxene concentrate.

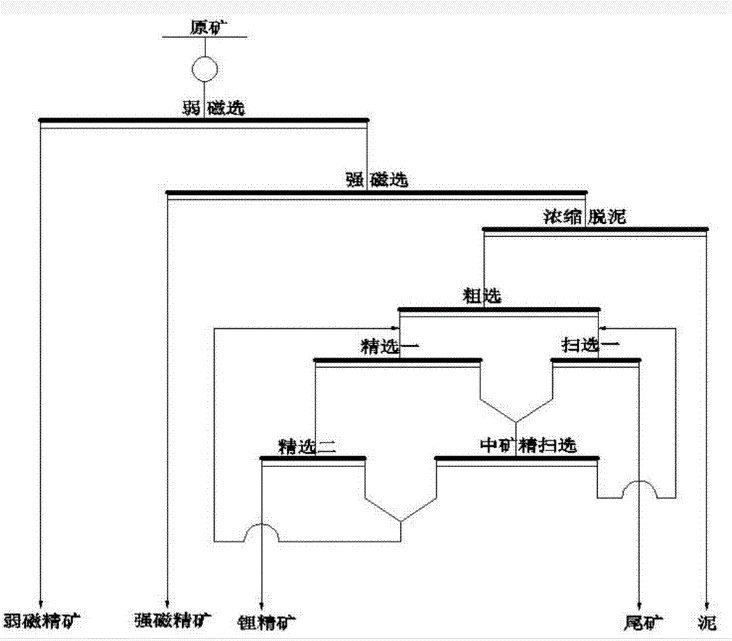

process flow

1.Flotation:Firstly, finely grind the lithium ore for flotation treatment. Then, during the flotation process, appropriate flotation and adjustment agents are used to separate lithium minerals from gangue minerals and obtain spodumene concentrate.

2.Strong magnetic separation:Perform strong magnetic separation on the lithium pyroxene concentrate obtained from flotation. Due to the weak magnetism of iron containing impurity minerals in spodumene, these minerals can be effectively separated from spodumene through strong magnetic separation. Strong magnetic separation is usually carried out using a wet strong magnetic separator, which adjusts parameters such as magnetic field strength and magnetic separation speed to achieve the removal of iron containing impurities.

3. Concentrate washing and drying:The spodumene concentrate after magnetic separation needs to be washed to remove suspended solids and excess flotation agents from the concentrate. Then, dry the washed concentrate to obtain a dry low iron spodumene concentrate.

Technological advantages

Efficient removal of iron impurities:

Improving lithium recovery rate:

Simplify subsequent processes:

Environmentally friendly:

Lithium ore magnetic separation process is an efficient and environmentally friendly lithium concentrate treatment method, suitable for removing iron impurities in lithium concentrate or separating weakly magnetic iron lithium mica. Through this process, high-quality low iron spodumene concentrate can be obtained, providing good raw materials for lithium extraction and processing.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron ore reverse flotation process

- Iron Ore Roasting and Magnetic Separation Process

- Lithium Ore Processing: Gravity Separation and Flotation

- Manganese ore washing to achieve the best results

- Manganese Ore Separation: Gravity and Magnetic Methods

- Manganese Ore Reduction Roasting and Magnetic Separation Process

- Molybdenite Grinding and Separation Process

Leave a message with your needs or comments

Add comment: