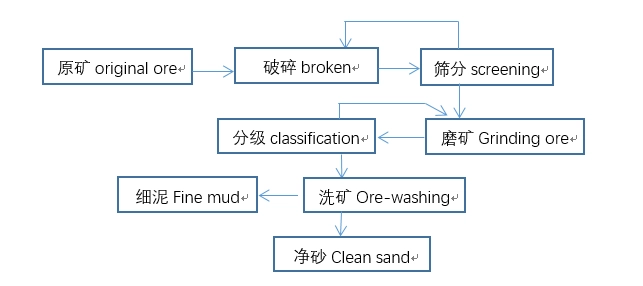

Mineral washing mainly utilizes hydraulic flushing or additional mechanical scrubbing to separate the ore from the mud. Common equipment includes washing screens, cylindrical washing machines, and trough washing machines. Usually, ore washing operations are accompanied by screening operations, such as directly washing with water on a vibrating screen or sending the ore sand (clean ore) obtained by the washing machine to the vibrating screen for screening. Screening can be used as an independent operation to separate products of different particle sizes and grades for different purposes.

Washing ore can cause the clay carried or attached to the surface of the ore to break and disperse, achieving the separation of ore and mud, and improving the ore grade; Primary manganese oxide ore and manganese carbonate ore have lower mud content and lower degree of mud binding with the ore, generally belonging to easily washable ores; Accumulated manganese oxide ore and weathered manganese oxide ore have high mud content and cannot be easily washed by hydraulic flushing to obtain qualified concentrates; The mineral processing product is called clean sand, which is used for the next step of processing or as the final concentrate.

Typical beneficiation plant

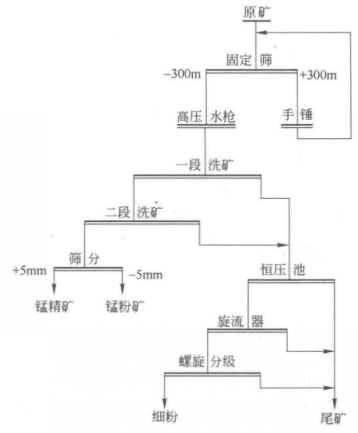

Guangxi Tiandeng Manganese Ore Dressing Plant has a manganese grade of about 17%, iron content of about 6%, and an average phosphorus content of about 0.1%. It belongs to low phosphorus, medium iron, high silicon, and poor manganese ores; The natural type of ore is mainly manganese oxide ore, with a small amount of primary manganese carbonate ore. Manganese minerals mainly include amorphous colloidal metamanganate, potassium hard manganese ore, ensu ore, and soft manganese ore, while gangue minerals mainly include kaolinite, quartz, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity separation+roasting+magnetic separation+gravity beneficiation process

- Floatability flotation process for lead-zinc ore

- Nickel ore magnetic separation+flotation combined process(Sulfide ore)

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Lithium ore heavy medium beneficiation process

- Lithium Ore Processing: Gravity Separation and Flotation

- Manganese ore washing to achieve the best results

Leave a message with your needs or comments

Add comment: