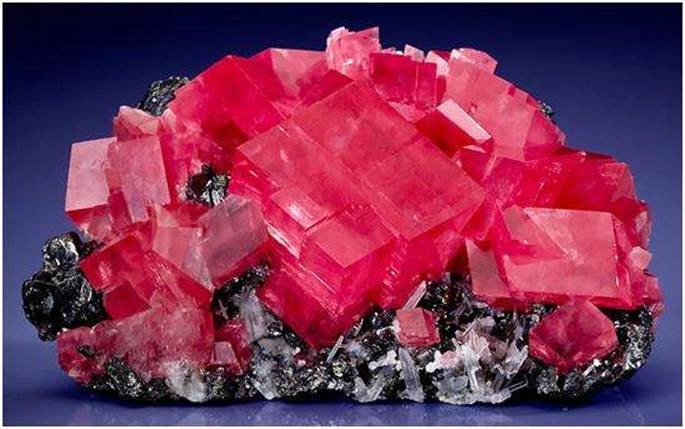

At present, more than 150 types of manganese minerals and manganese containing minerals have been discovered, with more than 20 commonly found, mainly including soft manganese ore, hard manganese ore, water manganese ore, black manganese ore, rhodochrosite, etc; The commonly used manganese ore beneficiation methods include washing, gravity separation, strong magnetic separation, flotation, pyrometallurgical enrichment, and hydrometallurgy.

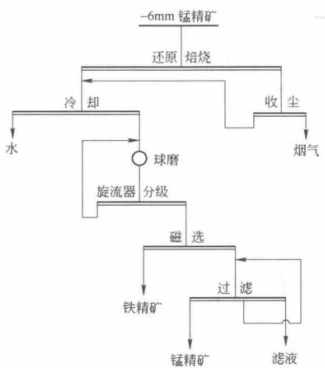

Manganese minerals often coexist with iron minerals in nature, and conventional methods are not easy to separate manganese and iron. Roasting technology is an effective method to achieve manganese iron separation.

The pyrometallurgical enrichment method of manganese ore is a method for treating difficult to select and poor manganese ores with high phosphorus and high iron content, commonly known as the rich manganese slag method. It mainly uses the different reduction temperatures of manganese, phosphorus, and iron to selectively separate manganese, phosphorus, and iron by controlling their temperature in a blast furnace or electric furnace.

The pyrometallurgical enrichment method has a simple process and stable production, which can effectively separate iron and phosphorus from ores, obtaining rich manganese, low iron, and low phosphorus rich manganese slag. This rich manganese slag generally contains Mn35-45%, Mn/Fe12-38. and P/Mn<0.002. It is a manganese alloy raw material, and is also an artificial rich ore that is difficult for natural rich manganese ore to achieve the above three indicators simultaneously. Therefore, the pyrometallurgical enrichment method is an effective mineral processing method for difficult mineral processing of high phosphorus, high iron, and low manganese.

Typical beneficiation plant

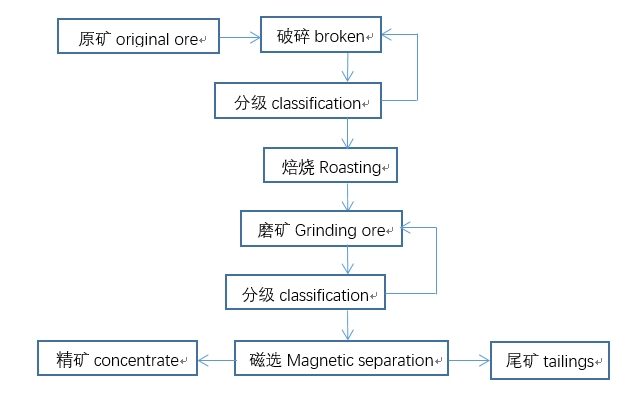

The Sera Donavio beneficiation plant mainly produces manganese minerals such as pyrolusite, hidden potassium manganese ore, and a small amount of black manganese ore. Gangue minerals include goethite, hydrated aluminum silicate, clay, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Combined Beneficiation Process

- Gold Mine Heap Leaching: Optimal Process

- Gravity combined beneficiation process for black and white tungsten ore

- Nickel ore priority flotation process(Sulfide ore)

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Manganese Ore Separation: Gravity and Magnetic Methods

- Manganese Ore Reduction Roasting and Magnetic Separation Process

Leave a message with your needs or comments

Add comment: