The combined process of tantalum niobium ore beneficiation and smelting is a method that combines physical beneficiation with chemical smelting, used to treat ores that are difficult to effectively separate by mechanical beneficiation or require high-grade concentrate. This process typically includes re selection, magnetic separation, and subsequent hydrometallurgy (water smelting) processes to directly obtain metal oxides or other valuable metal products.

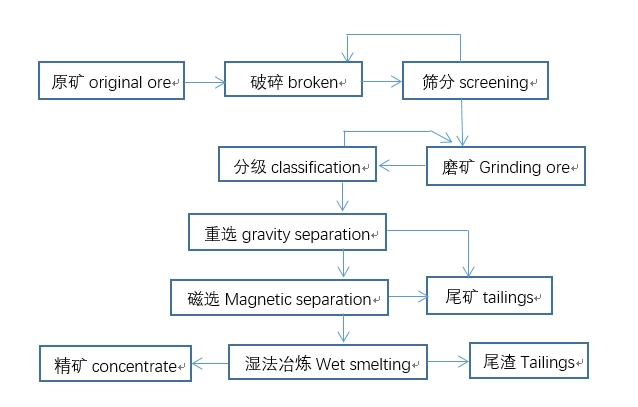

Process flow

1.Crushing and screening:Crushing the raw ore into smaller particles for the subsequent beneficiation process. Then, the minerals are separated according to their particle size through sieving.

2.Re selection:Use the density difference of minerals for separation. Re selection can be gravity beneficiation or strong magnetic beneficiation. Gravity beneficiation is usually used to first discard gangue minerals and obtain low-grade mixed coarse concentrate. Strong magnetic separation is used to further separate magnetic minerals.

3.Magnetic Separation:Further separation of magnetic minerals through a magnetic separator. This helps to improve the grade of the concentrate.

4.Hydrometallurgical process:Hydrometallurgical treatment is carried out on the concentrate after gravity and magnetic separation. Hydrometallurgical processes may include leaching, filtration, purification, electrolysis, or other chemical treatment steps to extract metals from concentrates.

5.Metal extraction and purification:In the process of hydrometallurgy, metals are extracted and purified to ultimately obtain metal oxides or other metal products.

Technological advantages

1.High efficiency:The combined process of beneficiation and metallurgy can effectively handle complex or variable ores, especially those that are difficult to separate through mechanical beneficiation methods.

2.High grade output:By combining physical beneficiation and chemical smelting, high-grade metal oxide products can be obtained.

3.High resource utilization:This process can fully utilize valuable metals in low-grade ores and improve resource utilization.

4.Environmentally friendly:Compared with traditional single ore dressing or smelting processes, the combined process of ore dressing and smelting reduces waste generation during the process, which helps to reduce environmental pollution.

5.Flexibility:The selection and smelting combined process can flexibly adjust process parameters based on the characteristics of the ore and the specifications of the required products to achieve the best production effect.

6.Economy:Although the initial investment may be high, the long-term operating cost of the selection and smelting combined process is low, and the economic benefits are significant.

The combined process of tantalum niobium ore selection and smelting is an efficient process that comprehensively utilizes physical and chemical methods. It can process various types of ores and obtain high-quality metal products.

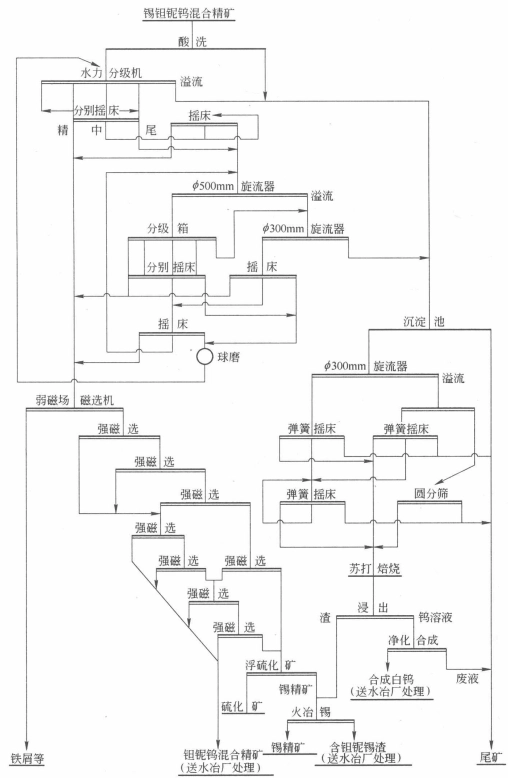

Typical beneficiation plant

Guangxi Limu Laohutou Selection Plant: The main useful minerals in the ore include cassiterite, cassiterite, colloidal tin, niobium manganese ore, manganese tantalum ore, titanium tantalum niobium ore, niobium iron ore, etc; Vein minerals include quartz, feldspar, etc.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore flotation+gravity separation+magnetic separation process

- Iron Ore Weak Magnetic Beneficiation Process

- Gold Mine Gravity Beneficiation Process

- Nickel Ore Mixing and Separation Flotation Process

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Effective Gravity Beneficiation for Chromium Ore

Leave a message with your needs or comments

Add comment: