The combined process of gravity separation, magnetic separation, and electrical separation of tantalum niobium ore is a comprehensive utilization of various physical separation methods to improve the separation efficiency and grade of tantalum niobium minerals.

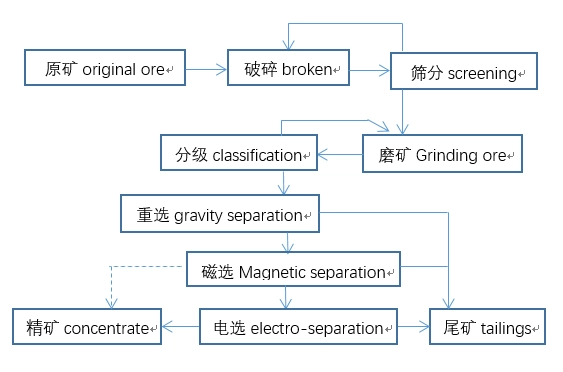

Process flow

1.Crushing and screening:Crushing the raw ore into smaller particles for the subsequent beneficiation process. Then, the minerals are separated according to their particle size through sieving.

2.Re selection:Use the density difference of minerals for separation. Re selection can be gravity beneficiation or strong magnetic beneficiation. Gravity beneficiation is usually used to first discard gangue minerals and obtain low-grade mixed coarse concentrate. Strong magnetic separation is used to further separate magnetic minerals.

3.Weak magnetic separation: mainly used for removing iron minerals from ores. By the action of a weak magnetic field, ferromagnetic minerals can be separated from non ferromagnetic minerals.

4.Strong magnetic separation:Used for recovering tantalum niobium minerals with weak magnetism. A strong magnetic field can better separate tantalum niobium minerals and further improve the grade of the concentrate.

5.Electroselection:Further sorting of minerals based on their differences in dielectric constants. Electric separation utilizes the different electrical properties of minerals in an electric field to achieve separation, which helps to further improve the purity of tantalum niobium minerals.

6.Concentrate Collection:Collect the concentrates separated from the above steps to obtain high-grade tantalum niobium mineral products.

Technological advantages

1.High efficiency:By combining multiple physical sorting methods, the sorting efficiency of tantalum niobium minerals can be effectively improved.

2.High grade output:This process can obtain high-grade tantalum niobium mineral products, meeting the needs of different industrial applications.

3.High resource utilization:It can fully utilize valuable metals in low-grade ores and improve resource utilization.

4.Environmentally friendly:Compared with traditional chemical beneficiation methods, physical beneficiation methods reduce waste generation during the process, which helps to reduce environmental pollution.

5.Flexibility:The process parameters can be flexibly adjusted according to the characteristics of the ore and the specifications of the required products to achieve the best production effect.

6.Economics:Although the initial investment may be high, the long-term operating cost of physical beneficiation methods is low, and the economic benefits are significant.

The combined process of gravity separation, magnetic separation, and electric separation for tantalum niobium ore is an efficient and environmentally friendly beneficiation method. It can improve beneficiation efficiency and product quality, while also having good economic and environmental benefits.

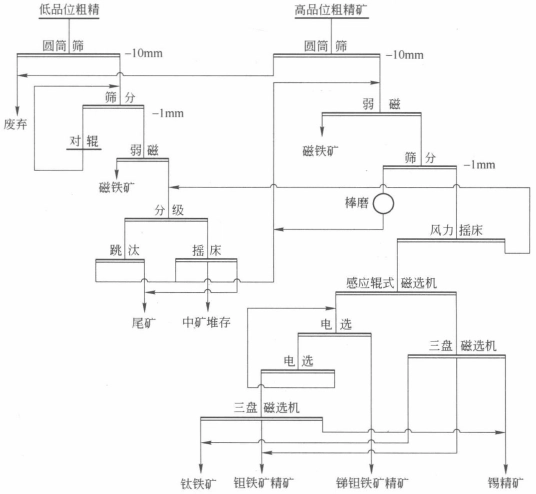

Typical beneficiation plant

Greenbush beneficiation plant: The ore is weathered clay pegmatite, composed of weathered quartz, mica, and tourmaline.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold Ore Carbon Slurry Beneficiation Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Branch serial flow flotation process for lead-zinc ore

- Uranium Ore Radioactive Treatment Process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Antimony Ore Hand Picking Process for Color Sorting

- Effective antimony ore gravity separation method

Leave a message with your needs or comments

Add comment: