There are more than ten types of antimony containing minerals with industrial utilization value, mainly including antimonite, antimonite, yellow antimony, red antimony, brittle sulfur lead antimony, antimony, etc. The commonly used beneficiation methods for antimony ore include manual beneficiation, gravity beneficiation, flotation, etc.

Based on the differences in color, luster, and other aspects between antimony ore and gangue minerals, high-quality concentrate products are manually sorted out; Hand selection is commonly used in antimony ore beneficiation plants.

Antimony ore is often found in coarse single crystal or blocky aggregate crystal forms. Due to the significant differences in color, luster, and shape between the antimony-containing minerals and the gangue in the ore, hand sorting is convenient. Although the method is primitive and requires a large amount of labor, hand sorting can often yield high-grade antimony concentrates, while directly discarding a large amount of waste rock, increasing the grade of the raw ore, and effectively reducing the production cost of beneficiation,因此 it is still widely used.

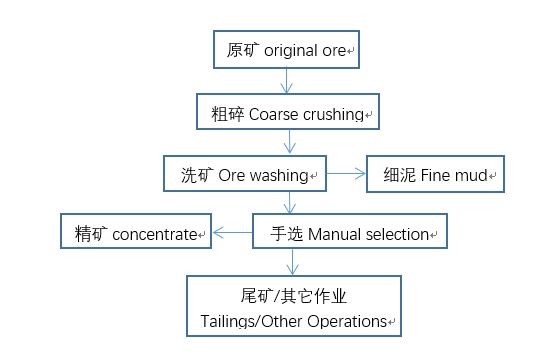

Hand sorting is generally suitable for particle sizes ranging from 28 to 150mm, and is usually done on the conveyor belt in the processing plant. However, some mines complete simple hand sorting operations in the pit or at the pit mouth. The blocky antimony concentrate obtained from hand sorting, containing more than 7% antimony, can then enter the smelting process to produce crude antimony. It is worth noting that in order to improve the efficiency of hand sorting, washing should be carried out before beneficiation to remove sludge impurities. The process flow and advantages are as follows:

Process Flow

1. Ore preparation: Crush and grind the ore to a suitable size for hand sorting.

2. Washing: Wash the ore to remove impurities and improve the quality of the antimony concentrate.

3. Hand sorting: Sort the ore manually based on the differences in color, luster, and shape between the antimony-containing minerals and the gangue.

4. Concentrate processing: Process the hand-sorted antimony concentrate to obtain crude antimony.

Advantages

1. High grade concentrate: Hand sorting can yield high-grade antimony concentrate, improving the economic value of the ore.

2. Waste rock reduction: By directly discarding waste rock during hand sorting, the amount of ore required for beneficiation can be reduced, saving costs.

3. Simplicity and cost-effectiveness: Hand sorting is a simple and cost-effective method for beneficiating antimony ore, especially in areas with abundant manual labor.

4. Environmental friendliness: Hand sorting minimizes the use of machinery and chemicals, reducing environmental impact.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Understanding the Gold Mine Flotation Process

- Carbon leaching beneficiation process for gold mines

- Cyanide Gold Preparation

- Branch serial flow flotation process for lead-zinc ore

- Floatability flotation process for lead-zinc ore

- Sulfide Ore Nickel Ore Mixed Flotation Process

Leave a message with your needs or comments

Add comment: