The reverse flotation process of bauxite is a mineral processing method mainly used to separate aluminum and silicon minerals from bauxite. Unlike the positive flotation process, the reverse flotation process first floats silicon minerals, and then floats aluminum minerals.

Reverse flotation process of bauxite

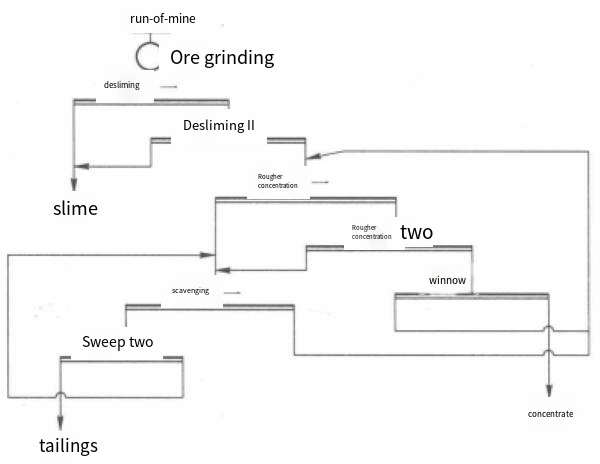

1.Ore preparation :

The raw ore undergoes coarse and fine crushing to a certain particle size for subsequent flotation treatment.

The ore is dried to remove moisture and improve flotation efficiency.

2.Medication preparation:

Flotation reagents include collectors, foaming agents, and adjusters. The collector is used to selectively adsorb on the surface of silicon minerals, the foaming agent is used to generate foam, and the regulator is used to adjust the pH of pulp and the surface properties of minerals.

3.Flotation machine separation:

The slurry is fed into the flotation machine, where the silicon and aluminum minerals in the slurry are separated under the action of reagents.

Due to the role of collectors, silicon minerals selectively adsorb on bubbles and float to the pulp surface to form a foam layer.

Aluminum minerals and impurities remain in the slurry and are not subjected to flotation.

4.foam collection:

The silicon minerals in the flotation foam layer are collected to form a concentrate of silicon minerals.

The collected foam is dehydrated to obtain a high grade silicon mineral concentrate containing a certain amount of water.

5.Reverse flotation:

After flotation of silicon minerals, the slurry is subjected to reverse flotation treatment, at which point aluminum minerals will be flotation.

The aluminum minerals in the pulp are selectively adsorbed on the bubbles due to the role of collectors, and float to the pulp surface to form a foam layer.

Silicon minerals and impurities remain in the slurry and are not subjected to flotation.

6.foam collection:

The aluminum minerals in the flotation foam layer are collected to form bauxite concentrate.、

The collected foam is dehydrated to obtain a high grade bauxite concentrate containing a certain amount of water.

7.Concentrate Treatment :

The concentrate is dried to remove moisture and obtain a dry bauxite concentrate.

Concentrates can also be further processed, such as calcination, electrolysis, etc., to extract aluminum metal.

Technological advantages

Efficient Separation:The reverse flotation process can effectively separate aluminum and silicon minerals in bauxite, improving the recovery rate of aluminum.

Reagent optimization: By optimizing the selection and use of flotation reagents, flotation efficiency can be improved and reagent costs can be reduced.

Flexible operation:The reverse flotation process is flexible and can adjust flotation conditions according to the properties and needs of the ore to achieve the best flotation effect.

The reverse flotation process of bauxite separates aluminum and silicon minerals from bauxite through the method of reverse flotation, which has the advantages of efficient separation, optimization of reagents, and flexible operation. This process plays an important role in bauxite beneficiation, providing effective technical support for the processing and utilization of bauxite.

Typical beneficiation plant

Henan Xiaoguan Aluminum Mine: In the original mine, monohydrate aluminum ore is the main useful mineral, while gangue is mainly illite, kaolinite, pyroxene, followed by rutile, quartz, etc; Cationic collector is used for reverse flotation. The foam product is silicon containing mineral, and the product in the cell is diaspore.

- Random article

- Popular articles

- Popular comments

- Copper ore stage grinding and selection process

- Positive flotation beneficiation process for bauxite

- Gold selection process using resin slurry method

- Gravity combined beneficiation process for black and white tungsten ore

- Prioritized Flotation Process for Lead-zinc Ore

- Lithium ore reverse flotation process

- Uranium Ore Radioactive Treatment Process

Leave a message with your needs or comments

Add comment: