The magnetic separation process of bauxite is a method of processing bauxite that contains a large amount of magnetic minerals. By utilizing the magnetic differences in the ore, it achieves the separation and enrichment of magnetic minerals and non-magnetic minerals.

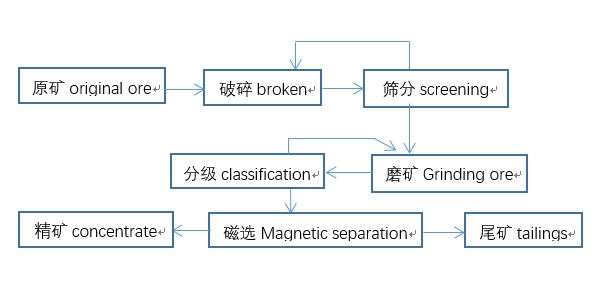

Bauxite magnetic separation beneficiation process flow

1.Raw ore preparation:

The raw bauxite ore undergoes coarse and fine crushing to a certain particle size for subsequent processing.

The ore is dried to remove moisture and improve magnetic separation efficiency.

2.Selection of magnetic separators:

Select appropriate magnetic separation equipment based on the characteristics of magnetic and non-magnetic minerals in the ore and the specific situation of the ore. Common magnetic separation equipment includes wet magnetic separators, dry magnetic separators, and high gradient magnetic separators. Different devices have differences in structure, working principles, and applicability, and need to be selected based on the properties and requirements of the ore.

3.Magnetic Separation Process:

Magnetic separation is the use of the different behaviors of magnetic and non-magnetic minerals in ores under an external magnetic field to achieve their separation. Magnetic minerals are magnetized by an external magnetic field, exhibiting magnetism; Non magnetic minerals do not undergo magnetization under external magnetic fields.

In the magnetic separation process, it is first necessary to magnetize the magnetic minerals in the ore. This can be achieved by placing the ore in a magnetic field or by applying an external magnetic field. Magnetization treatment can give magnetic minerals a certain degree of magnetism, providing conditions for subsequent separation.

The slurry is fed into the magnetic separation equipment, where magnetic and non-magnetic minerals in the slurry are separated from the ore. Magnetic minerals are enriched in magnetic separation tailings, while non-magnetic minerals are discarded.

4.Treatment of magnetic separation tailings:

The enrichment of bauxite minerals in magnetic separation tailings can be further carried out through flotation or gravity beneficiation to improve the comprehensive recovery rate of bauxite.

Magnetic separation tailings can also be further processed, such as calcination, electrolysis, etc., to extract aluminum metal.

Technological advantages

Efficient Separation:Magnetic separation technology can effectively separate magnetic and non-magnetic minerals in bauxite, improving the recovery rate of aluminum.

Improving concentrate quality:Through magnetic separation technology, magnetic minerals can be enriched in magnetic separation tailings, thereby improving the quality of bauxite concentrate.

Cost saving:Compared to other physical separation and chemical treatment methods, magnetic separation technology has the characteristic of being environmentally friendly. During the magnetic separation process, there is no need to add chemicals, which reduces environmental pollution and resource waste, and has a relatively small impact on the environment.

Flexibility in operation:The process operation is flexible, and the magnetic separation conditions can be adjusted according to the properties and needs of the ore to achieve the best magnetic separation effect.

The magnetic separation process of bauxite utilizes magnetic separation technology to separate magnetic minerals from non-magnetic minerals in bauxite with more magnetic minerals, and enrich them in magnetic separation tailings. This process has the advantages of efficient separation, improved concentrate quality, cost savings, and operational flexibility, providing effective technical support for the processing and utilization of bauxite.

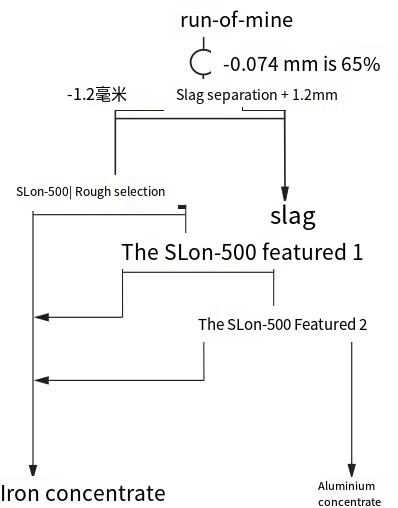

Typical beneficiation plant

Heqing Bauxite Mine in Yunnan Province: The ore is high iron bauxite, with aluminum as the main valuable element and iron and titanium as the main harmful elements. Aluminum exists in the form of monohydrate alumina, with iron minerals mainly consisting of hematite and limonite, and gangue minerals mainly consisting of kaolinite, plagioclase, quartz, and calcite.

- Random article

- Popular articles

- Popular comments

- Carbon leaching beneficiation process for gold mines

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Lithium ore reverse flotation process

- Lithium ore heavy medium beneficiation process

- Lithium Ore Processing: Gravity Separation and Flotation

- Chromite Gravity, Magnetic, and Electric Separation Process

- Effective antimony ore gravity separation method

Leave a message with your needs or comments

Add comment: