The selective flocculation beneficiation process for bauxite is a method that utilizes the principles of selective flocculation and stage grinding to separate useful minerals from gangue minerals. The following is a detailed introduction to the separation method of this process, which utilizes selective flocculation and stage grinding to increase the settling speed of useful minerals through flocculation and agglomeration, and separates them from fine and fine gangue. Through water washing and desliming, the target minerals and gangue minerals are separated.

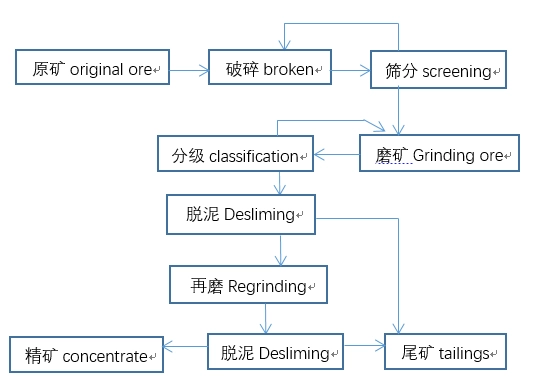

Selective flocculation beneficiation process flow of bauxite

1.Raw ore preparation:

The raw bauxite ore undergoes coarse and fine crushing to a certain particle size for subsequent processing.

The ore is dried to remove moisture and improve beneficiation efficiency.

2.Stage grinding:

Stage grinding is the process of dividing the raw ore into several different particle sizes for grinding. This can achieve better dissociation of useful minerals and gangue minerals, providing conditions for subsequent selective flocculation.

3.Selective flocculation:

Selective flocculation is the use of specific flocculants to form flocs of useful minerals, while gangue minerals do not form flocs or form smaller flocs.

Through flocculation and aggregation, the settling speed of useful minerals increases, separating them from fine-grained and micro grained gangue.

The flocculation process is usually carried out in a stirring tank, where useful minerals and gangue minerals form flocs under the action of flocculants.

4.Water washing and sludge removal:

Water washing and desliming is the process of separating flocs and fine-grained gangue through water flow. During the washing process, the flocs settle due to their high density, while fine vein stones are carried away by the water flow.

Water washing and desilting are usually carried out in a desilting hopper or tank, and the separation of flocs and fine-grained gangue is achieved by adjusting the water flow rate and the inclination of the desilting hopper.

5.Concentrate Collection:

After washing and desliming with water, useful minerals in the floc are collected to form bauxite concentrate.

The collected flocs are dehydrated and dried to obtain high-grade bauxite concentrate containing a certain amount of moisture.

6.Tailings treatment:

Tailings are fine-grained gangue and other impurities carried away by water flow during the washing and desilting process. The treatment of tailings usually includes steps such as concentration and drying to reduce its impact on the environment.

Technological advantages

Efficient Separation:The selective flocculation beneficiation process can effectively separate useful minerals and gangue minerals in bauxite, improving the recovery rate of aluminum.

Improving concentrate quality:By stage grinding and selective flocculation, the quality of bauxite concentrate can be improved.

Cost saving:The selective flocculation beneficiation process can save energy and reagent costs compared to traditional gravity and flotation processes.

Flexibility of Operation:The process operation is flexible, and the stage grinding and selective flocculation conditions can be adjusted according to the properties and needs of the ore to achieve the best beneficiation effect.

The selective flocculation beneficiation process of bauxite achieves effective separation of useful minerals and gangue minerals through steps such as selective flocculation, stage grinding, and water washing desliming. It has the advantages of efficient separation, improved concentrate quality, cost savings, and operational flexibility. This process plays an important role in bauxite beneficiation, providing effective technical support for the processing and utilization of bauxite.

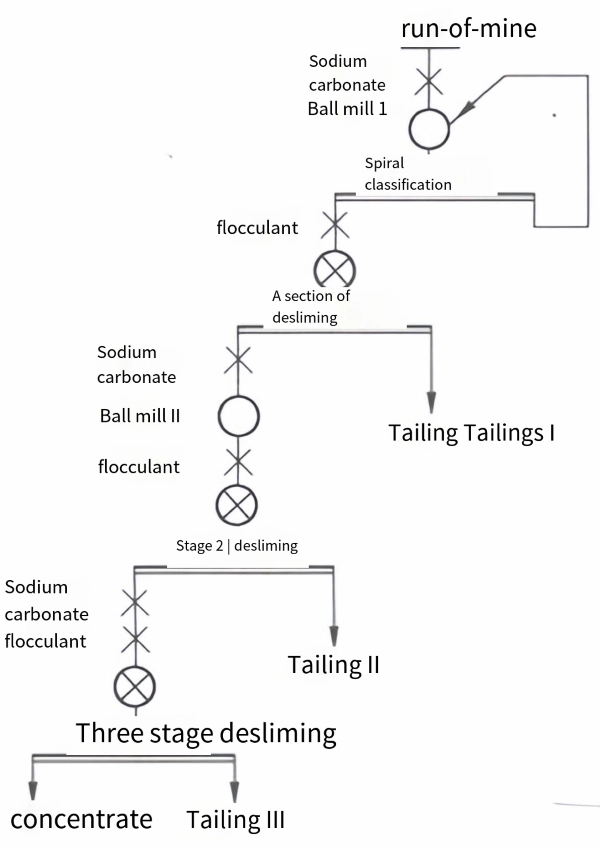

Typical beneficiation plant

Henan Bauxite: The useful minerals in the ore are diaspore, while the gangue minerals are mainly silicates and carbonates..

- Random article

- Popular articles

- Popular comments

- Gold Ore Carbon Slurry Beneficiation Process

- Cyanide Gold Preparation

- Gravity combined beneficiation process for wolframite ore

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Laterite Nickel Ore Hydrometallurgical Process for Oxide Ore

- Lithium ore positive flotation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

Leave a message with your needs or comments

Add comment: