The charcoal slurry process is mainly suitable for gold containing oxidized ores with high mud content. It is difficult to obtain good technical and economic indicators for this type of ore using the conventional cyanide method mentioned above. The reason is that the mud content is high, solid-liquid separation is difficult, and existing filters cannot effectively separate precious liquid and slag.

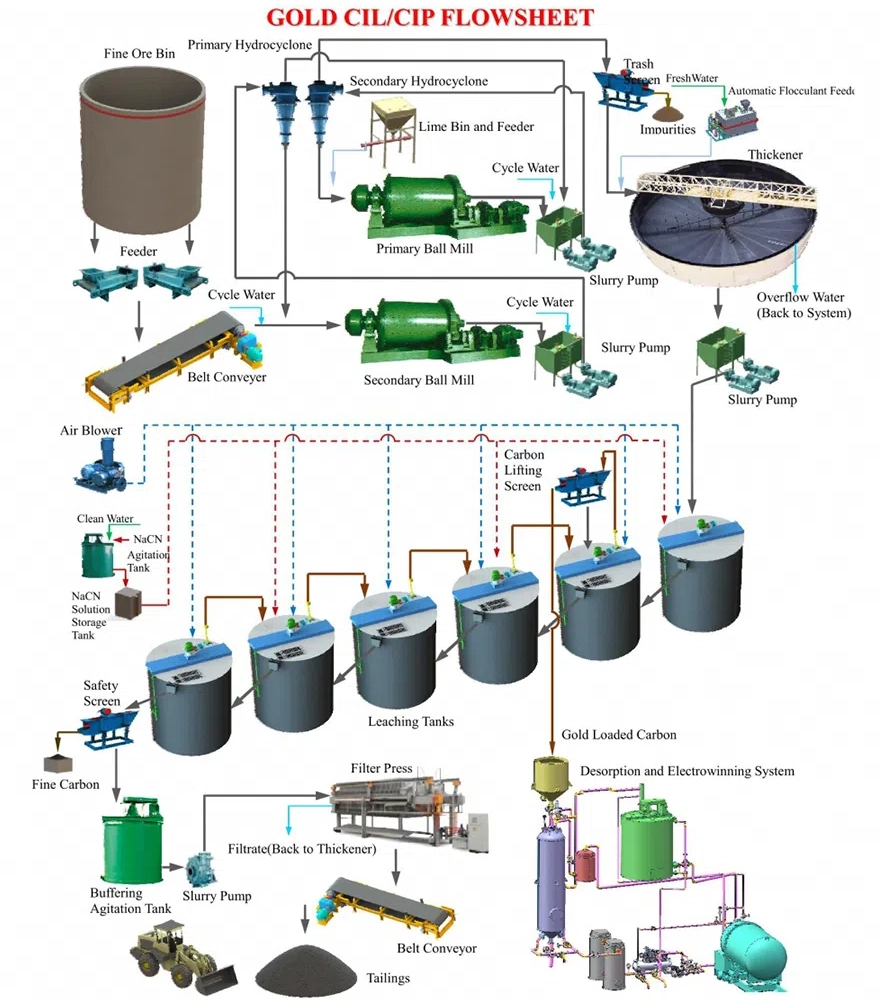

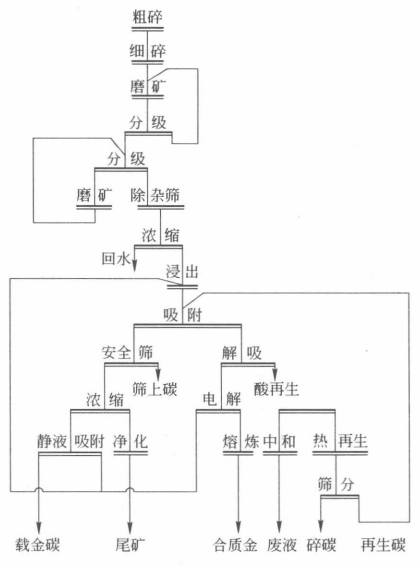

Carbon slurry gold extraction process flow

1.Cyanide leaching:The ore is first crushed and ground for chemical treatment. The ground ore is mixed with cyanide agents (such as sodium cyanide or potassium cyanide) and placed in a cyanide tank for leaching. Cyanides can dissolve gold and other metals in ores

2.activated carbon adsorption :After cyanide leaching, the slurry will contain dissolved gold ions. When a certain amount of activated carbon is added to the slurry, gold ions will preferentially adsorb on the surface of the activated carbon. The adsorbed slurry undergoes a washing process to remove unadsorbed cyanide and other impurities.

3.Extracting gold loaded charcoal:After adsorption and elution, the activated carbon (i.e. gold loaded carbon) is extracted and prepared for the next step of treatment.

4.Desorption:The gold loaded carbon releases the adsorbed gold ions back into the solution through the desorption process. This step typically involves heating and/or using desorption agents.

5.Electrowinning method for recovering gold:The gold containing solution obtained after desorption is introduced into the electrowinning equipment. During the electrodeposition process, gold ions deposit at the cathode, forming pure gold. The gold after electrowinning can be further purified to obtain high-purity gold products.

Characteristics of Carbon Slurry Gold Extraction Process

Good adaptability:The coal slurry method can process various types of gold mines, including oxidized ores, sulfide ores, and mixed ores. The recovery rate of soluble gold is high, and through the efficient adsorption of activated carbon, the recovery rate of soluble gold can reach over 90%.

Good economic efficiency:Compared with other gold extraction methods, the coal slurry method has better economic benefits in processing low-grade and complex ores.

Environmentally friendly:Although the cyanide process may generate harmful waste, through reasonable treatment and control, the impact on the environment can be minimized to the greatest extent possible.

Carbon slurry method, as an effective gold extraction technology, has been widely used in the gold mining and processing industry due to its high gold recovery rate and good economy. However, this process requires high levels of cyanide treatment and wastewater management to ensure environmental safety and meet the requirements of sustainable development.

Typical beneficiation plant

Linghu Gold Mine Dressing Plant: There are few metal minerals in the ore, with gangue minerals accounting for more than 90%. The main gold bearing minerals are natural gold, and the metal minerals are mainly limonite, magnetite, hematite, and a small amount of pyrite. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Roasting and Magnetic Separation Process

- Iron Ore Combined Beneficiation Process

- Sand gold beneficiation process

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Gravity combined beneficiation process for black and white tungsten ore

- Effective antimony ore gravity separation method

Leave a message with your needs or comments

Add comment: