Resin slurry method for gold selection is a process that uses ion exchange resin instead of activated carbon to adsorb gold ions in the slurry. This method has many advantages in the cyanide leaching process

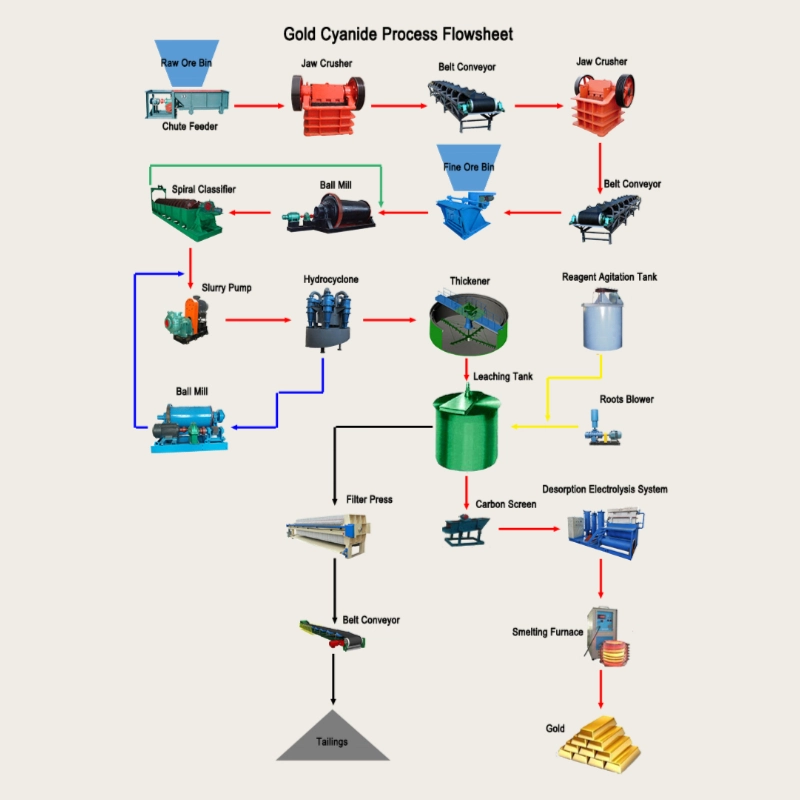

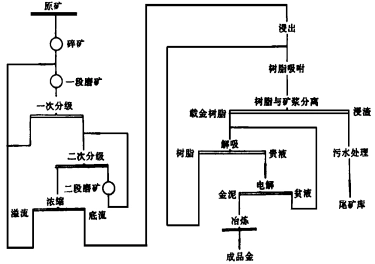

The process steps of gold selection using resin slurry method

1.Crushing and grinding:Similar to the coal leaching method, the mined gold ore is first crushed and ground to achieve appropriate fineness, facilitating contact and reaction between the cyanide agent and the gold ore.

2.Cyanide leaching:Mix the crushed ore with cyanide agents (such as sodium cyanide or potassium cyanide) and place it in a cyanide tank for leaching. Cyanides can dissolve gold and other metals in ores.

3.Resin adsorption:In the cyanide leaching process, specific ion exchange resins (usually strong acidic cation exchange resins) are used instead of activated carbon. Resin has strong adsorption capacity and can quickly adsorb gold ions in the slurry.

4.Continuous mixing and spraying:In the cyanide tank, the mixture of slurry and resin is continuously stirred or sprayed to ensure that the cyanide agent fully reacts with the ore, while the resin can effectively adsorb gold ions.

5.Resin regeneration:After a certain period of adsorption, the resin will saturate and require regeneration. The regeneration process usually involves using solvents such as dilute sulfuric acid or hydrochloric acid to wash off the gold ions adsorbed on the resin.

6.Gold recovery:The washed resin is washed to remove adsorbed impurities, and then sent to a desorption device. Through heating and chemical treatment, gold is desorbed from the resin to form a gold containing solution.

7.Electrodeposition or Permutation:Gold containing solutions can be further processed by electroplating or displacement methods to obtain pure gold.

Characteristics of gold selection process using resin slurry method

Fast resin adsorption speed:The adsorption rate of ion exchange resin for gold ions is usually faster than that of activated carbon, which improves production efficiency.

Large adsorption capacity:Resin can adsorb high concentrations of gold ions, improving the recovery rate of gold.

Small gold loss:The resin exhibits good selective adsorption of gold ions, reducing the loss of gold during the adsorption process.

Operational flexibility:Resin can be easily regenerated, restoring adsorption capacity and improving equipment utilization.

Environmentally friendly:The use of resin reduces the contact of cyanide and the generation of wastewater, with minimal environmental impact.

Resin slurry method for gold extraction is an efficient, fast, and environmentally friendly gold extraction process. It utilizes the high adsorption performance of ion exchange resin to achieve efficient recovery of gold. However, this process has high requirements for resin selection and regeneration treatment to ensure the extraction efficiency of gold and environmental protection.

Typical beneficiation plant

Anhui Guankou Iron Hat Gold Mine: The ore has a high degree of oxidation, high mud content, and high viscosity. The metal minerals in the ore are mainly limonite, with a small amount of hematite, magnetite, etc., and the non-metallic minerals are mainly quartz, feldspar, calcite, etc. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Bauxite Gravity and Flotation Process

- Understanding the Gold Mine Flotation Process

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Basic techniques for antimony ore flotation processing

- Understanding the Manganese Ore Flotation Process

- Combined Process for Quartz Sand Production

Leave a message with your needs or comments

Add comment: