Flotation method is a widely used beneficiation method in gold ore beneficiation plants, commonly used to treat highly floatable sulfide minerals containing gold ore. Gold is flotation into copper and lead concentrates, and then gold is extracted from these concentrates. Therefore, it is a more economical and reasonable process flow for gold ore containing non-ferrous metals in the original ore. It can achieve comprehensive utilization of multiple metals and enrich gold as much as possible into sulfide minerals.

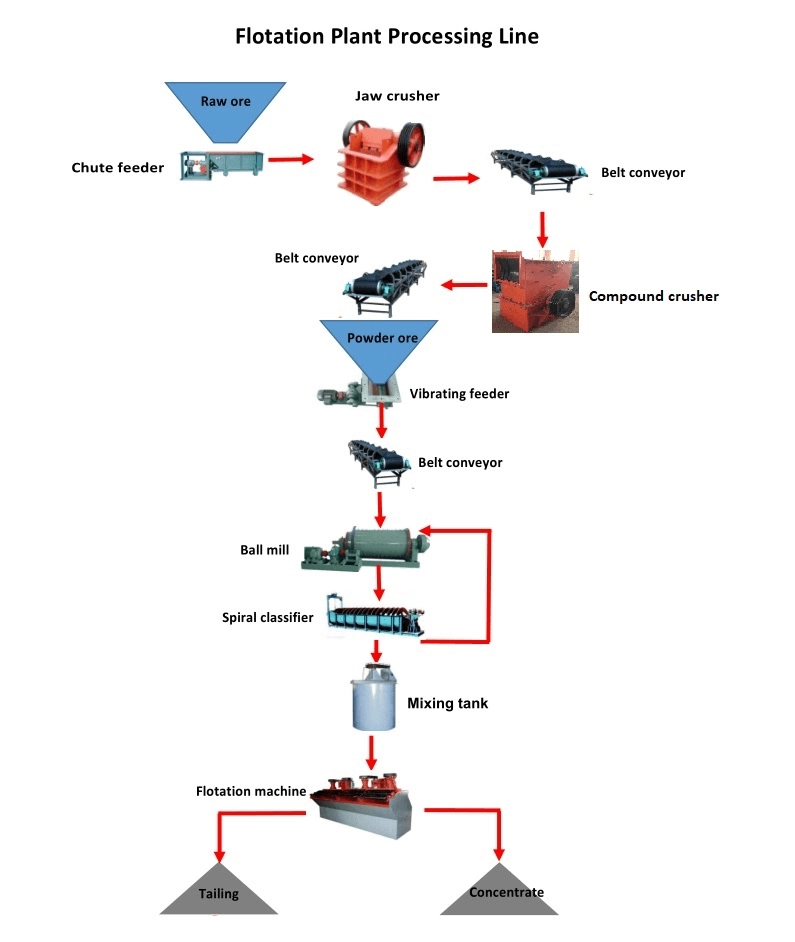

The gold ore flotation process is a crucial step in the extraction of gold from its ore. This process involves the use of a flotation machine, which utilizes the principle of hydrophobicity to separate valuable minerals from gangue minerals. The process begins with the crushing, grinding, and screening of the gold ore to prepare it for the flotation process. Once the ore is finely ground, a mineral processing agent is added to create a froth that carries the valuable minerals to the surface for further refinement. The process also involves the classification of the ore particles and the management of mine tailings to ensure environmental sustainability.

The first step in the gold ore flotation process is the preparation of the ore for flotation. This involves the crushing of the ore into smaller particles, followed by grinding to further reduce the size of the particles. The ground ore is then screened to separate the finer particles from the coarser ones. This preparation is essential to ensure that the ore is in an optimal state for the flotation process, as it increases the surface area for the interaction between the ore and the flotation reagents.

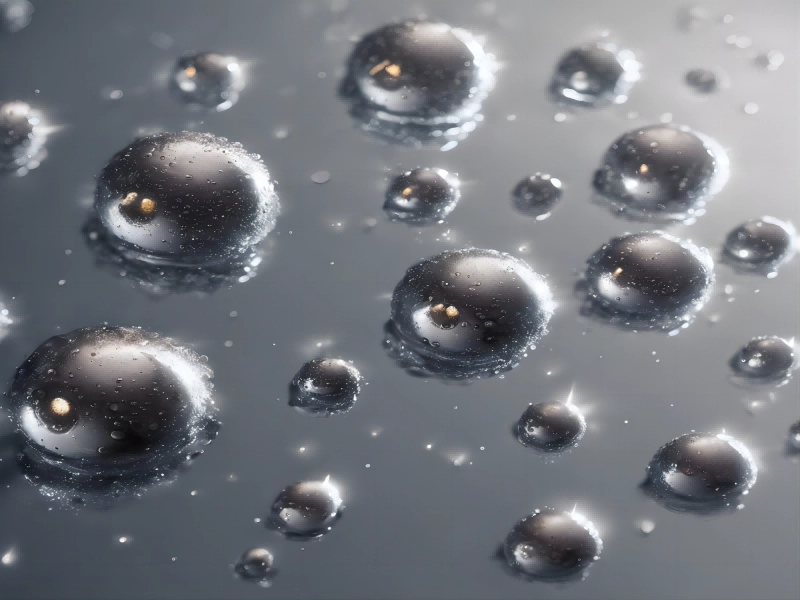

Once the ore is prepared, it is subjected to the flotation process using a flotation machine. This machine utilizes the principle of hydrophobicity, where air bubbles are introduced into the slurry to selectively adhere to the valuable minerals, causing them to float to the surface as a froth. A mineral processing agent, such as a collector or frother, is added to the slurry to facilitate the attachment of the air bubbles to the valuable minerals. This froth is then skimmed off to separate the valuable minerals from the gangue minerals, resulting in a concentrate that undergoes further refinement.

In addition to the flotation process, the classification of the ore particles is crucial in ensuring the efficiency of the process. This involves separating the particles based on their size and density, as well as their mineral composition. Proper classification ensures that the flotation machine can effectively separate the valuable minerals from the gangue minerals, leading to a higher recovery of gold from the ore. Furthermore, the management of mine tailings is an integral part of the gold ore flotation process. Tailings are the by-products of the flotation process and must be carefully managed to minimize their environmental impact. This includes the proper disposal and containment of tailings to prevent the release of harmful substances into the environment, as well as the potential reprocessing of tailings to recover any remaining valuable minerals.

the gold ore flotation process is a complex and essential step in the extraction of gold from its ore. It involves the use of a flotation machine, the addition of mineral processing agents, and the careful management of mine tailings. The process begins with the crushing, grinding, and screening of the ore, followed by the flotation process to separate the valuable minerals from the gangue minerals. Proper classification of the ore particles and the responsible management of mine tailings are crucial for the efficiency and environmental sustainability of the gold ore flotation process.

Combination of flotation and other processes

Flotation concentrate cyanide leaching:This gold ore beneficiation method is commonly used to treat gold deposits containing gold quartz veins and gold pyrite quartz veins. Generally, yellow medicine is used as a collector, pine alcohol oil is used as a foaming agent, and weakly alkaline slurry is used to flotation gold concentrate in a flotation machine. Then the flotation concentrate is subjected to cyanide leaching, where the gold is dissolved by cyanide and the complex enters the solution. The gold mud is then replaced with zinc powder to obtain pure gold. Finally, the gold mud is pyrometallurgical refined to obtain pure gold.

Flotation concentrate thiourea leaching:For vein gold ores with high arsenic and sulfur content or high carbon and mud content, flotation can be used to obtain gold sulfide concentrate, and then the flotation concentrate is leached with thiourea to recover gold.Thiourea method for gold extraction is a new and increasingly sophisticated low toxicity gold extraction process. Thiourea acidic solution has a high dissolution rate of gold and silver, low toxicity, and is easy to regenerate. Antimony, arsenic, copper, sulfur and other mineral components are not sensitive to thiourea for gold extraction, but can affect cyanide extraction of gold. Therefore, thiourea leaching can extract gold and silver from gold bearing mineral ores that are difficult to process by cyanide method. Meanwhile, the leaching time of thiourea for gold is generally much shorter than that of cyanide leaching.

Flotation concentrate roasting high acid washing cyanide leaching:For flotation concentrates with high arsenic and sulfur content, after flotation, impurities such as sulfur, iron, and arsenic are enriched in the cyanide tailings to become difficult to select high sulfur and high arsenic concentrates. When cyanide leaching is not possible, the flotation gold concentrate can be first oxidized and roasted to remove arsenic and sulfur. This way, the roasted sand structure is loose, which is more conducive to the leaching of gold and silver. Subsequently, high acid pretreatment was used for washing, and most of the impurities were dissolved by acid. After washing, they were removed, ensuring the cyanide leaching rate and effectively enriching the grade of gold.

Gold ore resources are extremely precious, and in order to select ores more reasonably, the gold ore beneficiation process is crucial. To select gold from gold ore in a more economical and environmentally friendly way, it is necessary to first conduct beneficiation tests, comprehensively analyze the properties of the ore, and obtain a scientific beneficiation test report to determine which gold ore beneficiation process to use. After considering the actual situation of the gold ore beneficiation plant, investment and other factors, the beneficiation plan should be determined to achieve the ideal investment return rate.

Typical beneficiation plant

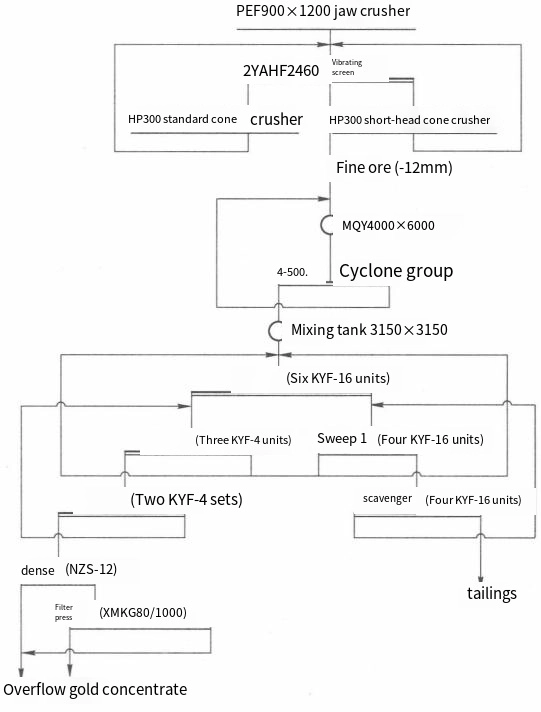

Shandong Dayin Gezhuang Gold Mine Dressing Plant: This mine is a low sulfur gold ore, with the main metal minerals being pyrite and silver gold. Silver gold is mostly produced in the form of fissure gold, and natural gold is mainly composed of interstitial gold and encapsulated gold; Adopting a full flotation process, the concentrate grade is around 55g/t.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Roasting and Magnetic Separation Process

- Iron Ore Combined Beneficiation Process

- Gold Mine Combined Beneficiation Process

- Carbon leaching beneficiation process for gold mines

- Cyanide Gold Preparation

- Gravity combined beneficiation process for wolframite ore

- Nickel ore priority flotation process(Sulfide ore)

Leave a message with your needs or comments

Add comment: