The carbon leaching process is one of the main methods of gold extraction from gold ores, which involves adding activated carbon to the pulp while simultaneously carrying out leaching and gold adsorption. Developed from the carbon-in-pulp method, the carbon leaching process integrates the cyanide leaching pulp and activated carbon adsorption into a single step. This effectively reduces the number of leaching tanks, shortens the process flow, and lowers the capital investment costs for infrastructure. Therefore, the carbon leaching process for gold extraction has been widely adopted.

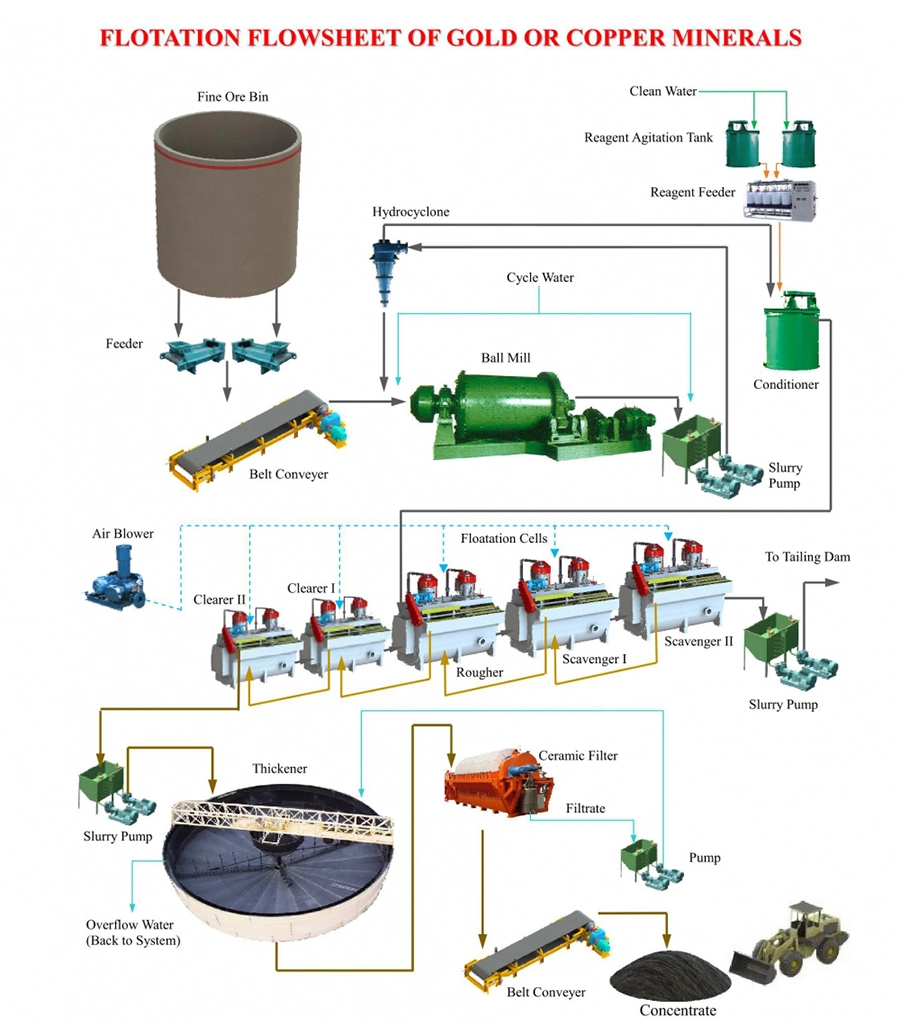

Carbon leaching process flow

1.Crushing and grinding:The mined gold ore is crushed and ground to achieve appropriate fineness, which facilitates better contact and reaction between the cyanide agent and the gold ore.

2.Cyanide leaching:Mix the crushed ore with cyanide agents (such as sodium cyanide or potassium cyanide) and place it in a charcoal leaching tank. Cyanides can dissolve gold and other metals in ores.

3.activated carbon adsorption :During the cyanide leaching process, activated carbon powder is added to the slurry. The surface of activated carbon has strong adsorption capacity, and gold ions will preferentially adsorb on the surface of activated carbon. adsorption

4.Continuous mixing and spraying:In the charcoal leaching tank, a mixture of slurry and activated carbon is continuously stirred or sprayed to ensure that the cyanide agent fully reacts with the ore, while activated carbon can effectively adsorb gold ions.

5.Treatment after adsorption:After a certain period of adsorption, the slurry will be filtered to separate activated carbon containing gold ions. Then, wash the activated carbon to remove adsorbed impurities.

6.Gold recovery:The washed activated carbon is sent to the desorption device, where gold is desorbed from the activated carbon through heating and chemical treatment, forming a gold containing solution.

7.Electrodeposition or Permutation:Gold containing solutions can be further processed by electroplating or displacement methods to obtain pure gold.

Characteristics of Charcoal Immersion Process

Efficient and continuous:The carbon leaching method combines cyanide leaching and activated carbon adsorption, achieving an efficient and continuous production process.

Low investment cost:Due to the lack of additional activated carbon adsorption equipment, the investment cost of carbon leaching method is relatively low.

Energy conservation and environmental protection:The carbon leaching method reduces energy consumption, while also reducing the use of cyanide and the generation of wastewater.

High recovery rate:The carbon leaching method can improve the recovery rate of gold, especially for low-grade ores.

Carbon leaching, as an efficient, economical, and environmentally friendly gold extraction process, has been widely used in the gold mining and processing industry. However, this process has strict requirements for the treatment of cyanide and the management of wastewater to ensure environmental safety and compliance with environmental standards.

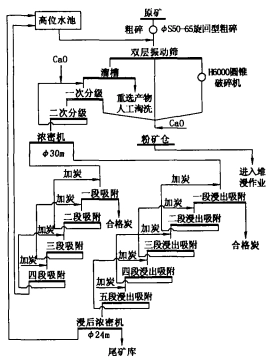

Typical beneficiation plant

Zijinshan low-grade gold deposit: Gold in the ore mainly exists in the form of natural gold, with a small amount in microscopic form. Natural gold is mainly dissociated gold, and a small amount is associated with copper minerals in iron ore. The specific process is as follows

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Scheelite Flotation Method

- Lead zinc ore mixing+separation flotation process

- Nickel ore priority flotation process(Sulfide ore)

- Zirconium Ore Processing: Gravity Separation and Flotation

- Efficient purification of manganese ore by magnetic separation process

- Molybdenite Grinding and Separation Process

Leave a message with your needs or comments

Add comment: