At present, there are only about 10 types of zirconium minerals with industrial value, mainly including zircon, hafnium containing zircon, and anisotropic minerals. The commonly used beneficiation methods include gravity separation, magnetic separation, electric separation, and flotation.

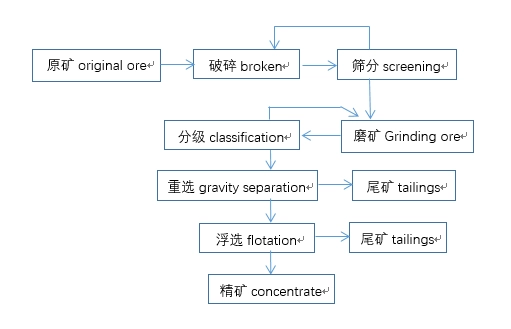

Gravity separation+flotation process

After crushing and grinding, some tailings are discarded through gravity separation, and the concentrate is re selected for flotation enrichment.

Process characteristics

High grade concentrate and low dosage of reagents.

Typical beneficiation plant

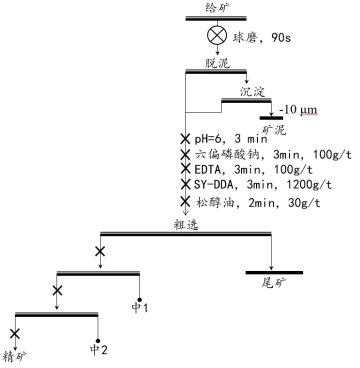

Inner Mongolia zircon ore, the main components of the ore include zircon, feldspar, quartz, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Carbon leaching beneficiation process for gold mines

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Lead zinc ore mixing+separation flotation process

- Manganese ore washing to achieve the best results

- Complete Manganese Ore Gravity Separation Process

- Efficient purification of manganese ore by magnetic separation process

- Understanding the Manganese Ore Flotation Process

Leave a message with your needs or comments

Add comment: