At present, there are only about 10 types of zirconium minerals with industrial value, mainly including zircon, hafnium containing zircon, and anisotropic minerals. The commonly used beneficiation methods include gravity separation, magnetic separation, electric separation, and flotation.

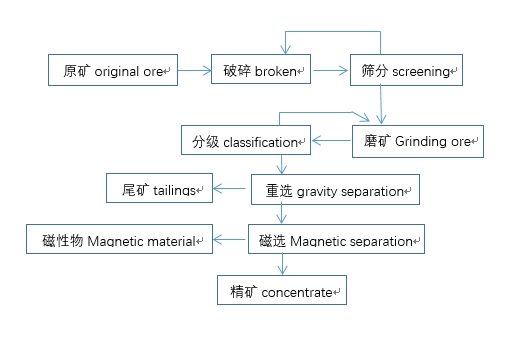

Gravity separation+magnetic separation process

Generally, the raw ore of sand ore is first screened to remove coarse sand without ore such as shells and gravel, and then a large amount of tailings are discarded through gravity separation. The coarse concentrate is separated by magnetic separation to obtain zircon concentrate and magnetic products.

Process characteristics

simple process and mature equipment.

Typical beneficiation plant

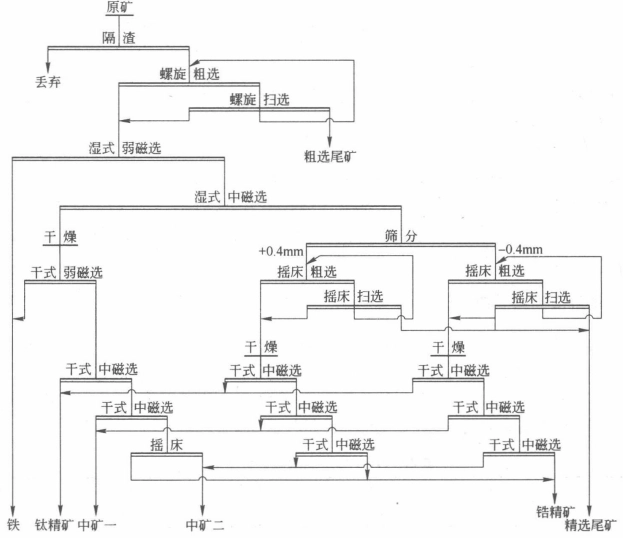

The Haizhou Zirconia Mineral Processing Plant in North Korea is a typical coastal placer mine, with raw ore containing magnetite, ilmenite, zircon, and a small amount of monazite. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Gravity combined beneficiation process for black and white tungsten ore

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Manganese Ore Separation: Gravity and Magnetic Methods

- Efficient Tantalum-Niobium Ore Separation: Gravity vs. Flotation

- Fluorite Ore Flotation Process for Quartz Type

- Barite Fluorite Ore Flotation Process for Efficient Separation

Leave a message with your needs or comments

Add comment: