At present, uranium is mainly extracted from uranium ores, and uranium containing phosphate ores, uranium containing copper mines, and uranium containing gold mines are also used as objects for uranium extraction; Most uranium ore in mines is directly subjected to chemical leaching after crushing and grinding. The beneficiation process of uranium ore is not a necessary part of uranium extraction. Only when the beneficiation operation can reduce production costs, will the beneficiation process be added to the uranium ore development process. Ordinary gravity separation, magnetic separation, and flotation methods are less commonly used in uranium ore beneficiation, while radioactive beneficiation is more commonly used.

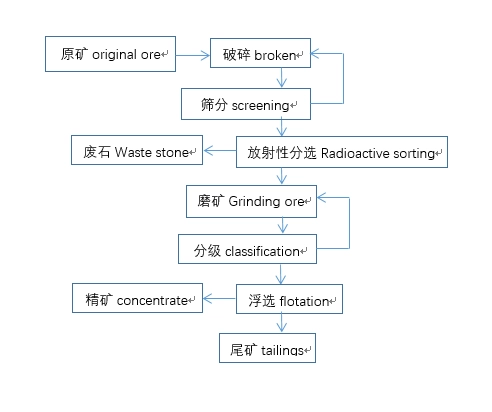

Radioactive beneficiation flotation process

After crushing and grading, part of the waste rock is first discarded through radioactive sorting, and the coarse concentrate enters the flotation process through grinding and grading.

Process features

High product grade.

Typical beneficiation plant

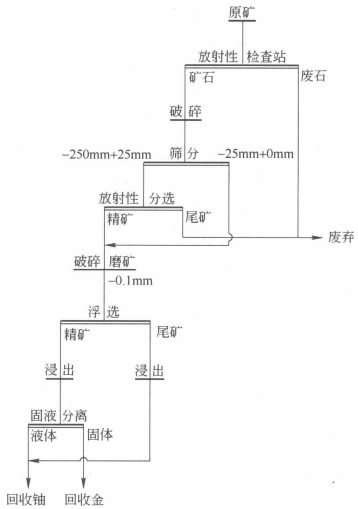

The Alikang uranium ore dressing plant in Russia is a vein type uranium deposit with aluminosilicate type ore. The uranium minerals are mainly titanium uranium ore, and the gold, silver, and other elements contained in the deposit need to be comprehensively recovered. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Gold Ore Thiourea Beneficiation

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Lithium Ore Processing: Gravity Separation and Flotation

- Radioactive beneficiation and flotation process for uranium ore

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Chromite Gravity and Magnetic Separation Process

Leave a message with your needs or comments

Add comment: