Copper ore priority flotation is a method of processing polymetallic ores, which first recovers one useful mineral through priority flotation, then recovers another useful mineral, and so on, until all useful minerals are recovered.

The commonly used flotation collectors include xanthates, black drugs, sulfur nitrogen compounds, lipids, and combination agents; Adjusting agents include sodium sulfide, lime, water glass, sodium sulfite, carboxymethyl cellulose, sodium humate, etc.

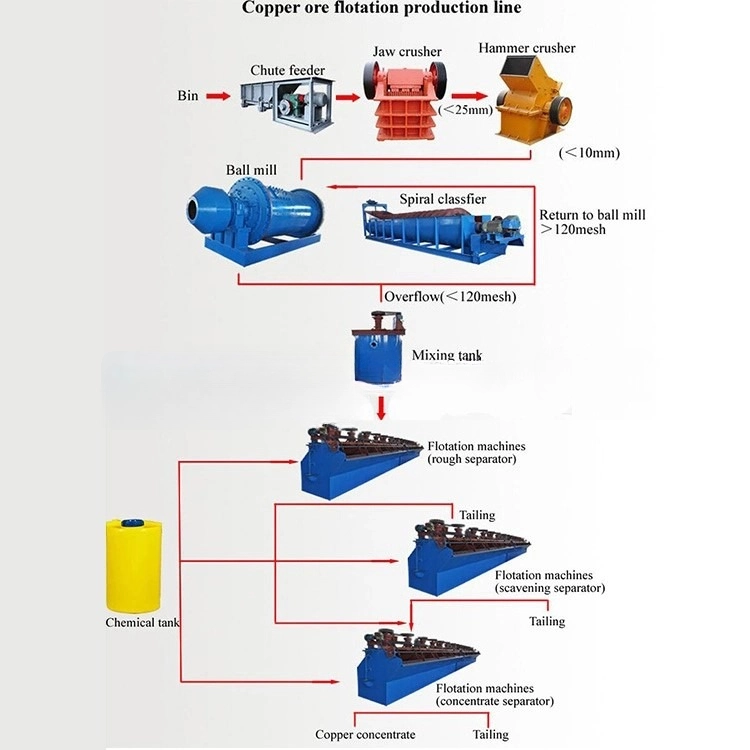

Process flow of copper ore priority flotation method

1.Ore crushing:Crush the extracted ore for subsequent flotation operations

2.Flotation machine flotation:Send the crushed ore into a flotation machine, and based on the physical properties of the minerals and the selection of flotation reagents, prioritize the flotation of one useful mineral.

3.Concentrate collection:Collect the flotation concentrate for subsequent processing.

4.Tailings treatment:Process the flotation tailings to recover other useful minerals that may exist within them.

5.Concentrate smelting:Smelt the collected concentrate to extract copper metal from it.

Typical beneficiation plant

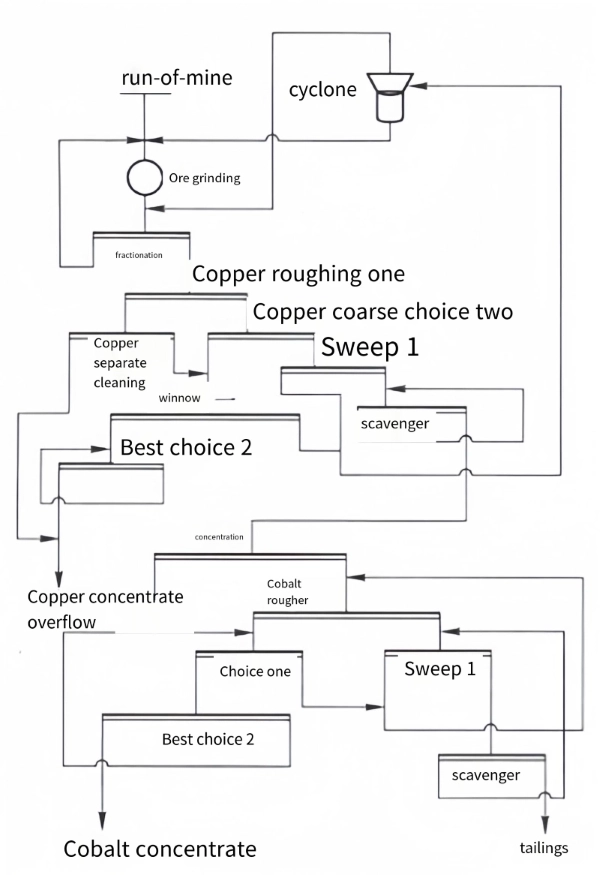

Shanxi Hujiayu Copper Mine Dressing Plant: The ore is a low sulfur and easy to select sulfide copper mine, with the main useful minerals being copper and cobalt minerals. Priority flotation method is used to recover copper and cobalt separately. The specific process is as follows:

Characteristics of copper ore priority flotation process

Selective separation:The priority flotation process can effectively separate copper minerals from other minerals and improve the recovery rate of copper. By using specific flotation agents, copper minerals can be selectively floated while other minerals remain in the slurry.

Efficient and energy-saving:Priority flotation usually needs to be carried out under milder conditions, such as lower temperatures and lower grinding fineness, which helps to reduce energy consumption and production costs.

Simplify the process:Compared with traditional flotation processes, priority flotation processes can simplify the process, reduce the number of equipment and maintenance costs.

Improve quality:Priority flotation process can obtain high-quality copper concentrate with high copper content and low impurities, which is beneficial for the subsequent smelting process

Strong adaptability:The priority flotation process is suitable for processing various types of copper ores, whether it is chalcopyrite, chalcopyrite, or other copper containing minerals, and can achieve good separation results by adjusting flotation conditions

environment protection:The priority flotation process uses relatively fewer flotation agents, which is beneficial for reducing the impact on the environment. Meanwhile, by effectively separating copper minerals, the processing capacity of tailings and environmental pollution can be reduced.

The advantages of copper ore priority flotation method are simple process, easy control of reagent conditions, stable indicators, and the ability to directly obtain a single mineral concentrate product. In addition, as it is a flotation method that first recovers one of the useful minerals, it can effectively avoid interference between useful minerals, improve flotation efficiency and concentrate purity.

- Random article

- Popular articles

- Popular comments

- Tin ore gravity+flotation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Chromium Ore Gravity Separation and Flotation Process

- Manganese Ore Reduction Roasting and Magnetic Separation Process

- Tantalum-Niobium Ore Gravity Separation Methods

Leave a message with your needs or comments

Add comment: