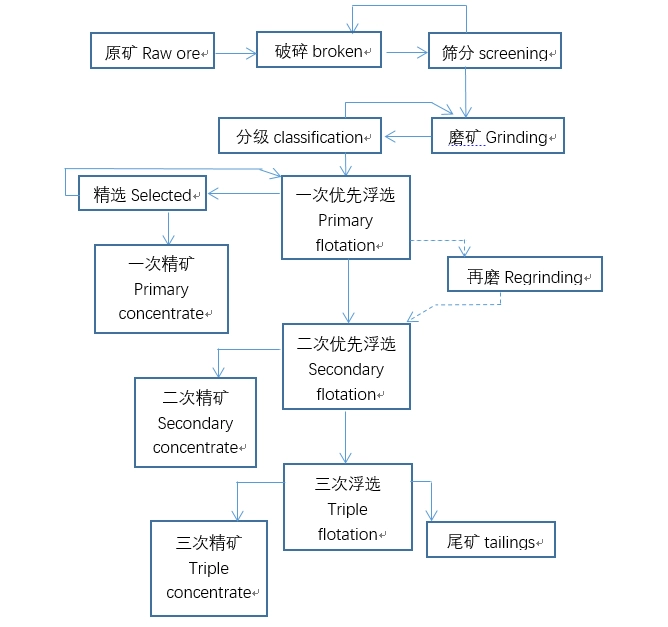

The step-by-step priority flotation method for copper ore is a flotation process that uses multiple floatations based on the properties of the ore to enrich useful minerals with coarser or more easily floatable embedded particles into a product. Then, the tailings from the first flotation stage are re ground or other chemical processes are used to sequentially select the remaining useful minerals.

The step-by-step priority flotation process for copper ore

1..Ore crushing:Crush the copper ore to an appropriate particle size for subsequent flotation operations.

2.Priority flotation:Based on the characteristics of the ore, select appropriate flotation reagents and conditions to enrich some useful minerals with coarser or more easily floatable embedded particles into a product.

3.Tailings regrinding:Re grind the tailings from the first flotation stage to achieve finer particle size for subsequent flotation operations.

4.Multi-stage flotation:Perform multiple floatations on the regrinding tailings sequentially, and select the remaining useful minerals separately.

5.Concentrate separation:Separate the concentrates obtained from different flotation stages to obtain concentrate products of different grades.

Characteristics of step-by-step priority flotation process for copper ore

1.It can effectively improve the grade of copper concentrate, which is beneficial for subsequent smelting and processing

2.Taking into account the characteristics of ores with different properties, the flotation process is stable and easy to operate, which is beneficial for improving flotation efficiency and reducing production costs.

3.Through multi-stage flotation, different grades of concentrates can be effectively separated, improving the economic benefits of the mine.

The step-by-step priority flotation method for copper ore is an effective flotation process for processing copper ore. It can use multiple flotation methods based on the properties of the ore to enrich useful minerals with coarser particle size or easier to float into a single product. Then, the tailings from the first flotation stage are re ground or other chemical processes are used to select the remaining useful minerals in order to obtain multi stage concentrate products. This method is beneficial for improving the grade of copper concentrate, reducing production costs, and improving the economic benefits of the mine.

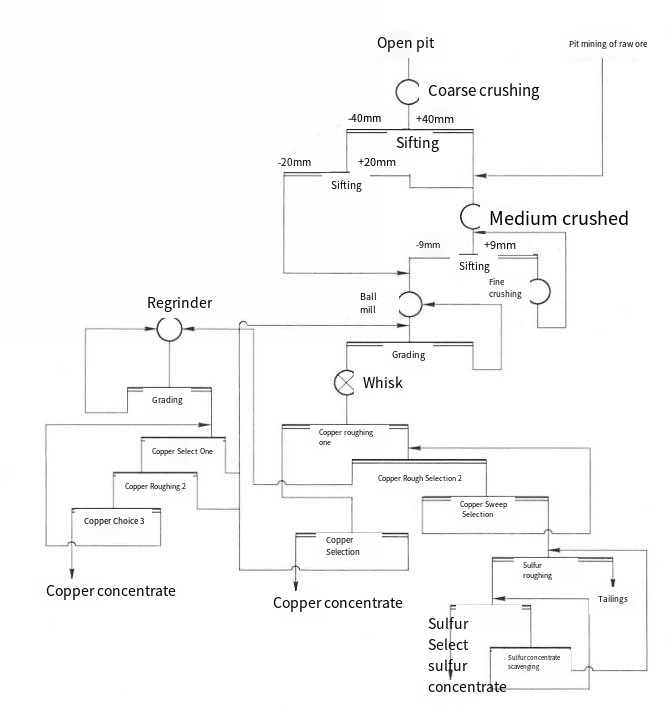

Typical beneficiation plant

Jiangxi Yongping Copper Mine Dressing Plant: The mine is a large open-pit deposit mainly composed of copper and sulfur, accompanied by various metals such as lead, zinc, silver, gold, etc. It adopts a step-by-step priority flotation process to first obtain some high-grade copper concentrate, then sweep and select the copper concentrate, grind and re select it, select copper tailings for sulfur, and obtain copper concentrate products and sulfur concentrate products respectively. The specific process is as follows

- Random article

- Popular articles

- Popular comments

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Nickel ore priority flotation process(Sulfide ore)

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- Chromite Gravity and Magnetic Separation Process

- Effective antimony ore gravity separation method

- Titanium Ore Processing: Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: