The copper mine adopts a combination of flotation, magnetic separation, or gravity separation treatment method, mainly to comprehensively recover the associated magnetic minerals or high-density minerals in the ore. This method can improve the utilization rate of ore while recovering valuable metal minerals.

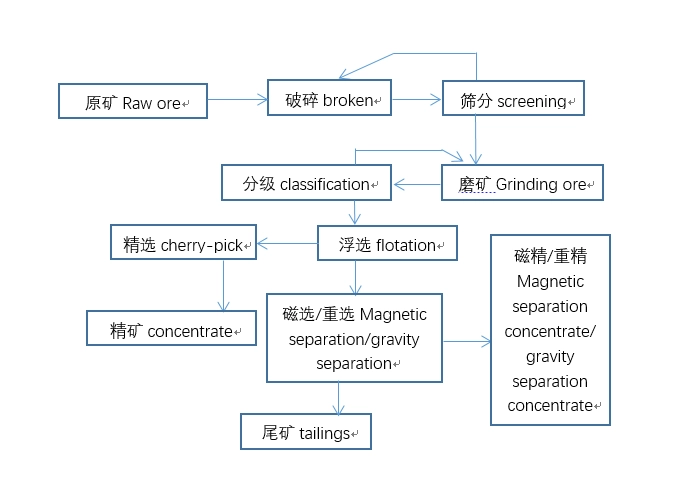

Copper ore flotation+magnetic (gravity) separation combined process flow

1.Ore crushing:Firstly, the ore is subjected to coarse and fine crushing to a certain particle size for subsequent mineral processing.

2.Magnetic or gravity separation:The crushed ore can be pretreated using magnetic or gravity separation methods. Magnetic separation is the process of separating magnetic minerals from non-magnetic minerals through a magnetic separator, utilizing the magnetic differences of magnetic minerals in ores. Re selection is the process of utilizing the density differences of different minerals in the ore to separate high-density minerals from low-density minerals through gravity beneficiation equipment such as heavy medium beneficiation machines or jigs.

3.flotation:The ore that has undergone magnetic or gravity separation pretreatment is then subjected to flotation treatment. Flotation is the process of separating useful minerals from gangue minerals by utilizing the differences in interaction between different minerals and flotation agents in the ore. In the flotation process, flotation agents such as collectors, foaming agents, and adjusters are added to promote the flotation of useful minerals.

4.Concentrate separation:The different mineral concentrates obtained from flotation can be further separated and processed, such as concentration and filtration, to obtain the final concentrate product.

5.Tailings treatment:The tailings generated during flotation, magnetic separation, or gravity separation processes need to be treated, including tailings storage, backfilling, or other treatment methods, to reduce their impact on the environment.

Characteristics of Copper Mine Flotation+Magnetic (Gravity) Separation Combined Process

1.comprehensive utilization:This method can comprehensively recover various valuable metals from ores, especially for copper mines containing magnetic or high-density minerals, which can effectively improve resource utilization.

2.Stage processing:Firstly, magnetic minerals or high-density minerals are separated by magnetic or gravity separation methods, and then flotation treatment is carried out to recover copper minerals. This phased processing method can improve the efficiency of mineral processing.

3.Selective flotation:In the flotation stage, by adjusting flotation conditions such as pH value, type and concentration of reagents, temperature, etc., high selectivity flotation of copper minerals and other minerals can be achieved, thereby improving the recovery rate of copper.

4.flexibility:This process method has high flexibility and can adjust the flotation conditions and sequence according to the specific properties of the ore and the flotation properties of various metals to adapt to different types of ore and metal compositions.

5.Efficient and energy-saving:Compared with single flotation, magnetic separation, or gravity separation processes, this combined process can more efficiently recover valuable metals while reducing energy consumption.

6.environment protection:Although the flotation process may produce some tailings and waste liquid, reasonable design and treatment can minimize the impact on the environment.

7.Economy:Through this method, the processing cost of ore can be reduced and economic benefits can be improved.

The copper mine adopts a combination of flotation, magnetic separation, or gravity separation treatment method, which can comprehensively recover the associated magnetic minerals or high-density minerals in the copper mine, improve the comprehensive resource recovery level, increase economic benefits, simplify the production process, and improve the grade of copper concentrate. This method has multiple advantages and is conducive to improving the economic benefits and sustainable development level of mines.

Typical beneficiation plant

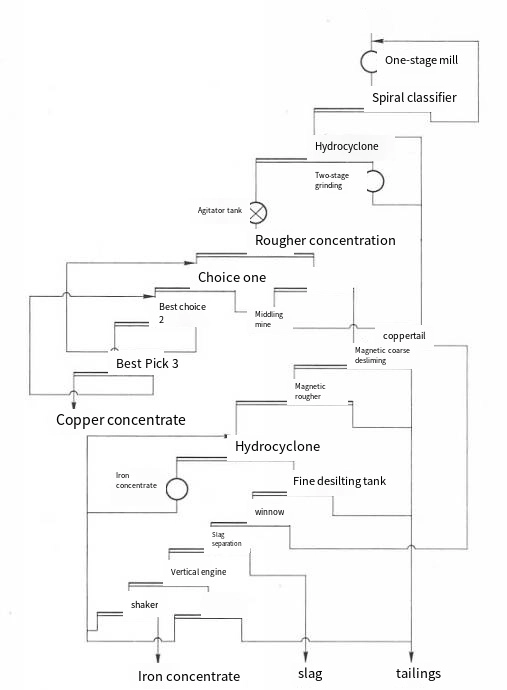

Yunnan Dahongshan Copper Mine Beneficiation Plant: The mine is composed of a large rich iron ore and a large iron copper ore. The beneficiation plant uses a combination of flotation and magnetic separation processes to obtain copper concentrate and iron concentrate, respectively. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Tin ore flotation processing technology

- How to Extract Gold Using Mercury

- Lead zinc ore mixing+separation flotation process

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Lithium ore positive flotation process

- Lithium ore reverse flotation process

Leave a message with your needs or comments

Add comment: