Copper ore mixed flotation method is a method for treating copper ore containing multiple useful minerals. Its main purpose is to enrich various useful minerals into a concentrate, and then separate different minerals from this concentrate to obtain different types of concentrate products. This method is commonly used to process copper ores containing two or more useful minerals, such as chalcopyrite, bornite, and chalcopyrite.

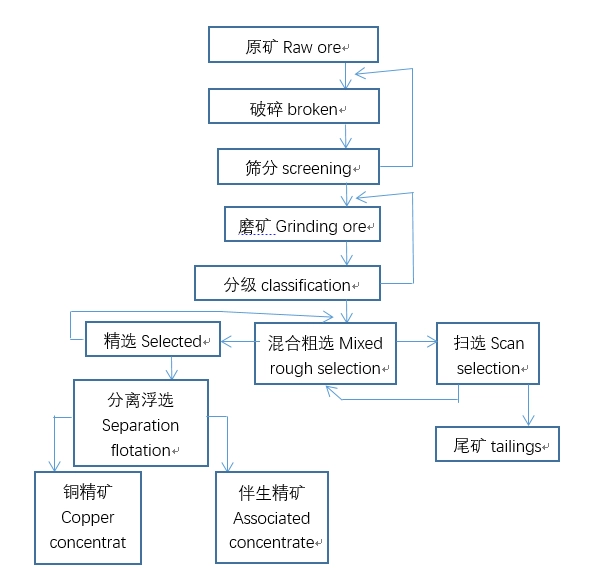

Copper ore mixed flotation process flow

1.Crushing and grinding:Firstly, the ore is preliminarily crushed by a crusher and then sent to a ball mill or rod mill for grinding, with the aim of grinding the ore into fine powder and fully dissociating useful minerals and gangue minerals.

2.Mixed flotation:The ground slurry is sent to the flotation machine for mixed flotation. In this process, various flotation agents such as collectors, foaming agents, and adjusters are added to promote the separation of useful minerals from gangue minerals. The goal of mixed flotation is to enrich two or more useful minerals together, forming an intermediate product containing multiple metals.

3.Mid stage product handling:The intermediate products obtained from mixed flotation usually require further treatment, such as concentration and dehydration, to reduce the volume of tailings and provide suitable materials for subsequent separation flotation.

4.Separation flotation:Separate and flotation the intermediate products to separate different metal components. This may require the use of different flotation agents and conditions to separate different minerals. The order and conditions of separation flotation depend on the flotation properties and priorities of various metals.

5.Concentrate products:By separating flotation, different types of concentrate products can be obtained, such as copper concentrate, lead concentrate, zinc concentrate, etc. These concentrates can be further processed and refined to obtain the final metal product.

6.Tailings treatment:The tailings generated during the flotation process need to be treated, including tailings storage, backfilling, or other treatment methods, to reduce their impact on the environment.

Typical beneficiation plant

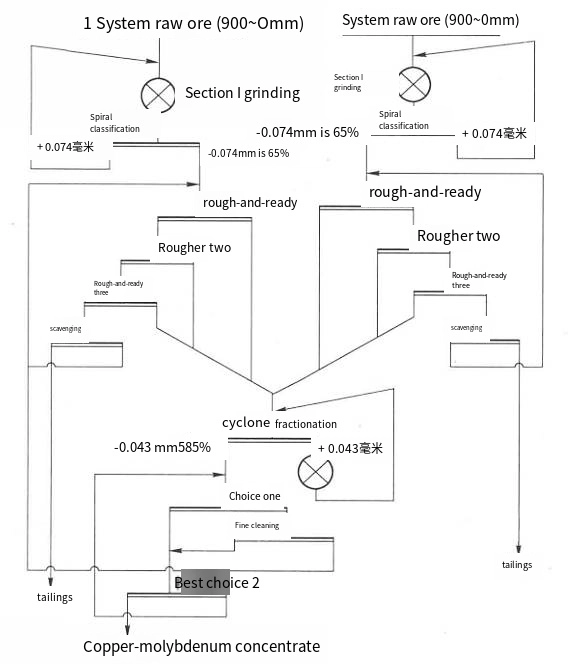

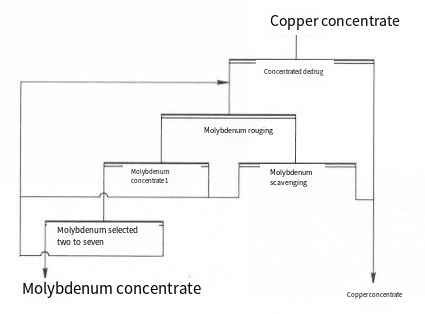

Hubei Daye Tongshankou Copper Mine Dressing Plant: The main useful minerals in the ore are copper molybdenum ore, single copper ore, and single molybdenum ore. The mixed flotation method is used to first obtain a copper molybdenum mixed concentrate, and then separate the mixed concentrate to obtain copper concentrate products and molybdenum concentrate products, respectively. The specific process is as follows

Characteristics of Copper Mine Mixed Flotation Process

Enrichment effect:The mixed flotation method first enriches various useful minerals in the ore into a single product, which helps to improve the efficiency and effectiveness of subsequent separation flotation.

flexibility:The mixed flotation method can flexibly adjust the flotation conditions and sequence according to the specific properties of the ore and the flotation properties of various metals, in order to adapt to different types of ores and metal compositions.

Efficiency:By concentrating multiple useful minerals together, the mixed flotation method can more efficiently carry out subsequent separation flotation, reduce losses in the flotation process, and improve metal recovery.

Economy:The mixed flotation method can reduce the use of flotation agents and the scale of flotation equipment, thereby reducing the cost of beneficiation and improving economic benefits.

environmental effect:Although the mixed flotation method has advantages in treating polymetallic ores, the tailings and waste liquid generated during the flotation process need to be properly treated to reduce their impact on the environment.

Copper mixed flotation method is an effective method for treating polymetallic ores, which has the characteristics of enrichment, flexibility, efficiency, and economy. However, this method also puts forward high requirements for the selection of flotation agents and the control of flotation conditions, which need to be optimized and adjusted according to specific ore properties.

- Random article

- Popular articles

- Popular comments

- Iron ore reverse flotation process

- Gold Ore Carbon Slurry Beneficiation Process

- Nickel ore priority flotation process(Sulfide ore)

- Lithium ore magnetic separation process

- Effective antimony ore gravity separation method

- Manganese Ore Reduction Roasting and Magnetic Separation Process

- Molybdenite Grinding and Separation Process

Leave a message with your needs or comments

Add comment: