Separation flotation method is a combination of pyrochemical treatment and flotation. For example, the separation flotation of difficult to select oxidized copper ore involves crushing the ore to a certain particle size, mixing a small amount of table salt (0.1-1.0%) and coal powder (0.5-2.0%), heating it to around 900 degrees Celsius through oxygen isolation, and the copper in the ore precipitates in a metallic state on the surface of carbon particles. The roasted sand is cooled through oxygen isolation and then ground for flotation to obtain copper concentrate.

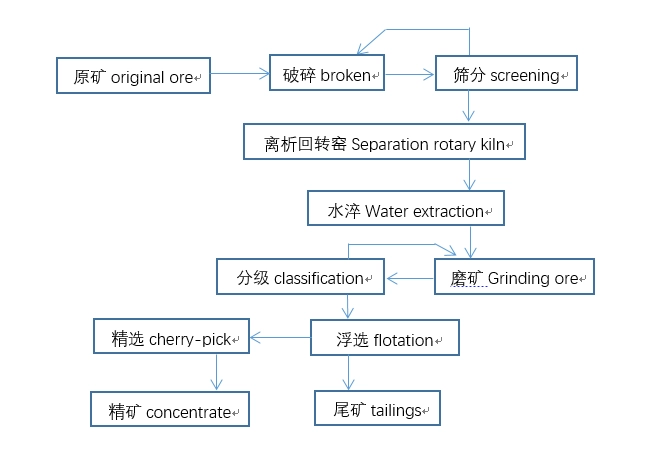

Copper ore oxidation-reduction separation+flotation process flow

1.Ore pretreatment:Crushing and grinding the ore to achieve a certain fineness is beneficial for subsequent pyrochemical treatment.

2.Pyrochemical treatment:Perform high-temperature sintering on the preprocessed ore to separate useful metals from gangue minerals. The commonly used pyrochemical treatment methods include reduction smelting, oxidation smelting, etc.

3.flotation:Flotation of ore after pyrochemical treatment, utilizing the density and surface properties differences between different minerals to separate useful metal minerals from gangue minerals. Common flotation methods include foam flotation, agglomeration flotation, jet flotation, etc.

Advantage

The biggest advantage of the separation flotation method is that it can solve the problems of ores that cannot be processed by conventional beneficiation methods. It can comprehensively recover useful metals from ores. For example, in copper ore, when the ore contains a large amount of silicon malachite, chalcopyrite, and bound copper, or when there is a large amount of ore mud, the flotation method often has low indicators, while the separation method is more effective. The segregation method can also process mixed ores of oxidized copper ore and sulfide copper ore, and can comprehensively recover useful metals such as gold, silver, and iron. In addition, compounds of several metals such as gold, silver, nickel, aluminum, cobalt, antimony, palladium, bismuth, tin, etc. are easy to reduce and generate volatile chlorides, which are also suitable for separation treatment.

Disadvantages

The disadvantages of the segregation method are high cost, large infrastructure investment, and high production costs. It is estimated that the infrastructure investment for the separation method is about twice that of a flotation plant with the same capacity, and the production cost is also 2-3 times higher. Therefore, when using the separation method to treat difficult to select oxidized copper ore, it is believed that the copper grade in the raw ore should be greater than 2% in order to achieve better economic results. So the segregation method is only used to solve ores that cannot be processed by other methods. Therefore, before adopting this method, a comprehensive study should be conducted on the processed ore. If other methods can be used for processing, the segregation method should not be used.

Typical beneficiation plant

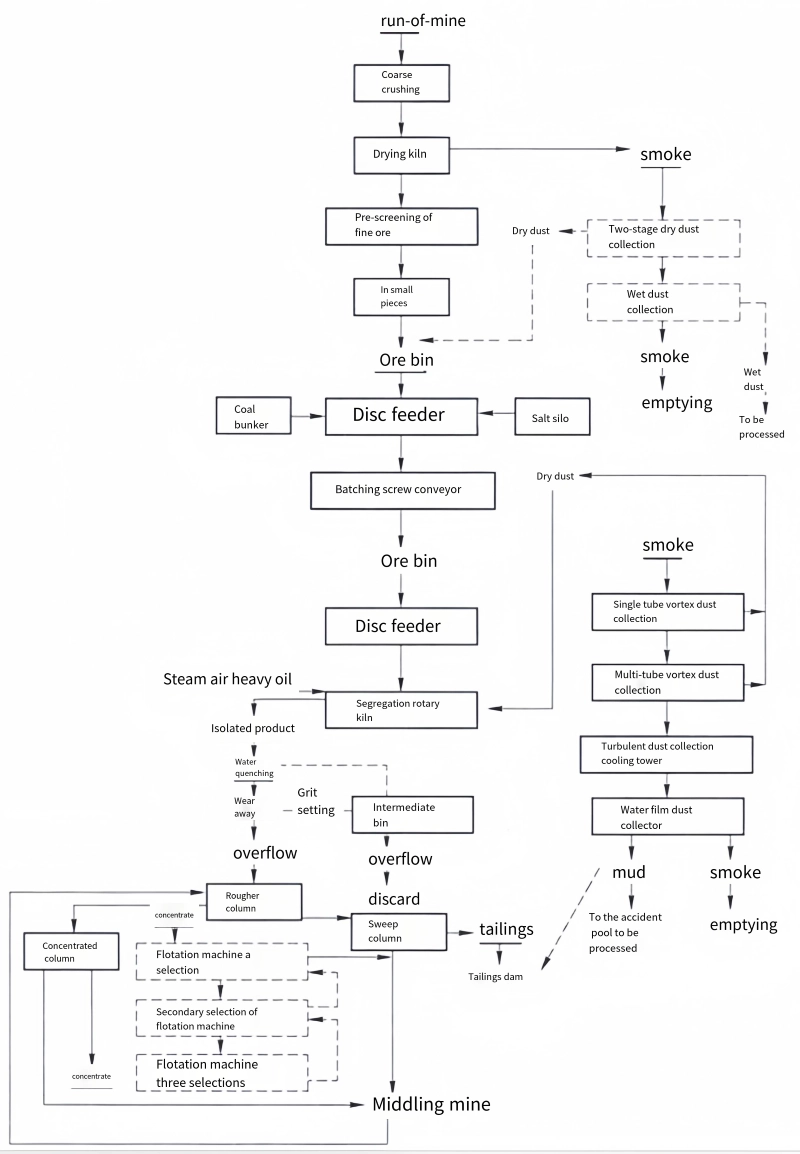

Guangdong Shilu Copper Mine Separation Flotation Plant: The ore belongs to the quartz diorite porphyry and limestone contact metasomatic skarn copper deposit, which is deeply difficult to select oxidized copper ore. The copper bearing minerals are mainly malachite, with a small amount of blue copper ore and silicon malachite. The plant adopts the separation flotation treatment process. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Bauxite Gravity and Flotation Process

- Iron Ore Combined Beneficiation Process

- Lithium ore reverse flotation process

- Lithium Ore Processing: Gravity Separation and Flotation

- Radioactive beneficiation and flotation process for uranium ore

- Zirconium Ore Processing: Gravity Separation and Flotation

- Chromium Ore Gravity Separation and Flotation Process

Leave a message with your needs or comments

Add comment: