Tantalum niobium ore beneficiation generally uses gravity separation to discard most of the gangue minerals and obtain low-grade mixed coarse concentrate. The coarse concentrate entering the beneficiation operation has a complex mineral composition and generally contains multiple useful minerals, making it difficult to separate. Multiple beneficiation methods such as gravity separation, flotation, electromagnetic separation, or combined beneficiation and metallurgy processes are usually used for separation of multiple useful minerals.

The gravity beneficiation process of tantalum niobium ore is a method of separation based on mineral gravity differences, which mainly utilizes the density differences between minerals to separate them.

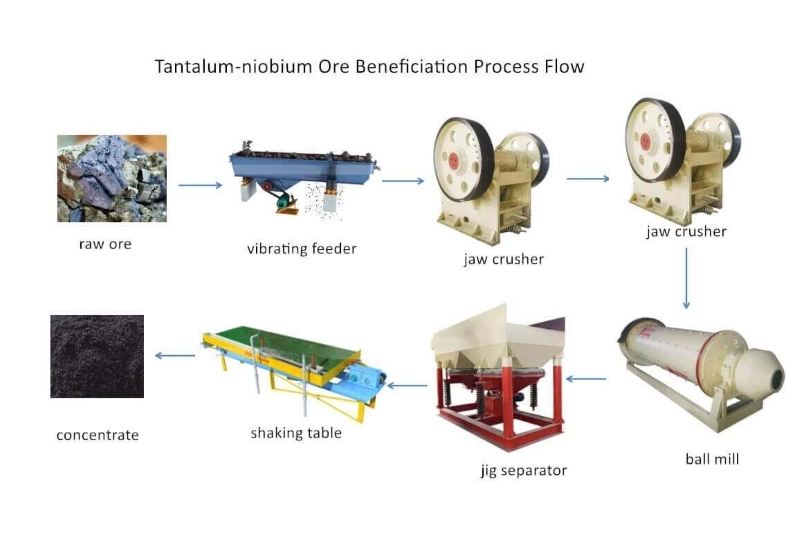

process flow

1.Crushing and screening:First, the raw ore is crushed into smaller particles, and then minerals of different particle sizes are separated through screening.

2.Density separation:Suspend minerals in water, and due to the different densities of minerals, their suspension positions in water will also vary. Heavier minerals will sink to the bottom, while lighter minerals will float to the top. By adjusting the flow rate and density of water, effective separation of minerals can be achieved.

3.Collection and concentration:Collect the separated minerals and increase their concentration through the concentration process.

Technological advantages

1.Efficient and energy-saving:The gravity beneficiation process utilizes the natural gravity of minerals for separation, without the need for additional energy input, thus having high energy utilization efficiency.

2.Environmentally friendly and pollution-free:Gravity beneficiation process does not involve the use of chemical agents and will not cause pollution to the environment. It is a green and environmentally friendly beneficiation method.

3.Strong adaptability:Gravity beneficiation technology is suitable for the separation of various minerals, especially for minerals with significant density differences, and has good separation effects.

4.Low cost:The gravity beneficiation process equipment is simple, easy to maintain, and has lower operating costs, which is beneficial for reducing beneficiation costs.

Gravity beneficiation technology has important application value in tantalum niobium ore beneficiation. It can effectively improve the separation efficiency of minerals, reduce beneficiation costs, and has the advantage of environmental protection and pollution-free.

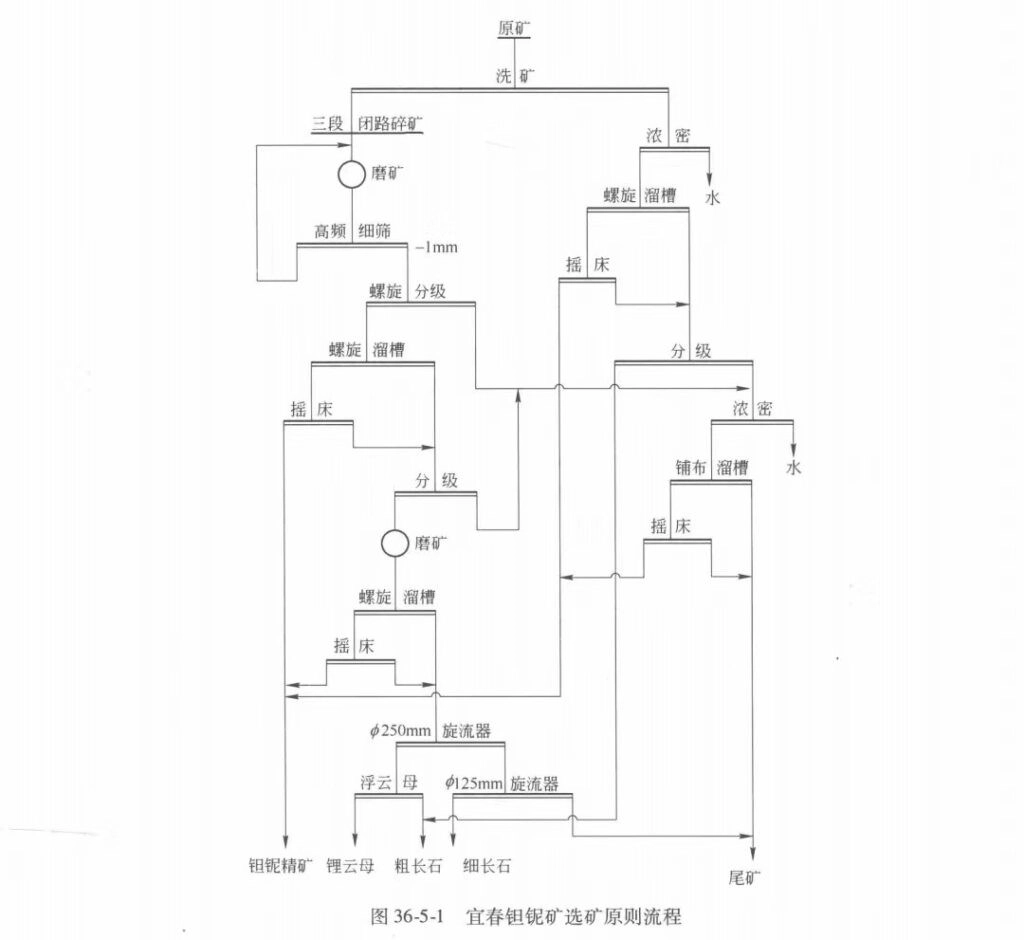

Typical beneficiation plant

Yichun Tantalum and Niobium Ore Dressing Plant: The main useful minerals in the ore are rich manganese niobium tantalum iron ore, fine-grained ore, tantalum cassiterite, lithium mica, etc.

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Iron Ore Weak Magnetic Beneficiation Process

- Gold Mine Gravity Beneficiation Process

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Effective Gravity Beneficiation for Chromium Ore

- Chromite Processing: Gravity, Magnetic, and Flotation Separation

- Effective antimony ore gravity separation method

Leave a message with your needs or comments

Add comment: