At present, industrial production mainly includes rutile, ilmenite, rutile, and perovskite; Most natural rutile is used for the production of titanium dioxide and metallic titanium, while ilmenite is generally processed and processed into synthetic rutile to produce titanium dioxide and metallic titanium. The beneficiation methods can be divided into two categories: ilmenite beneficiation and rutile beneficiation.

The beneficiation process of ilmenite mainly depends on the deposit and ore properties. The primary ilmenite beneficiation process is mainly divided into two parts: iron beneficiation and titanium beneficiation. Iron beneficiation is mainly carried out through magnetic separation, and the titanium beneficiation process includes magnetic separation, flotation, gravity separation electric separation, gravity separation magnetic separation flotation processes, etc; The beneficiation process of placer ilmenite is divided into two parts: rough selection and selection. Rough selection generally uses ore washing or gravity selection, while selection often uses methods such as magnetic separation and electric separation.

Due to low grade, fine particle size, and high impurities, primary rutile ore is often treated using methods such as gravity magnetic separation, gravity magnetic separation electrical separation, gravity magnetic separation flotation, flotation magnetic separation, as well as roasting and acid washing; Placer rutile is generally progressiveness ore washing or gravity separation, and coarse concentrate is further separated and enriched by magnetic separation, electric separation, gravity separation and other methods.

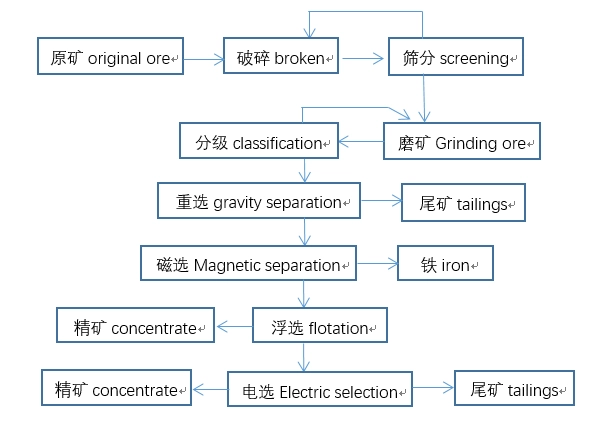

Gravity separation+magnetic separation+flotation+electric separation process

After crushing and grinding the raw ore, it undergoes gravity separation for tailings, magnetic separation for iron removal, flotation for sulfur removal, and electric separation to ultimately obtain qualified titanium concentrate products.

Process characteristics

Multiple product types and high grade.

Typical beneficiation plant

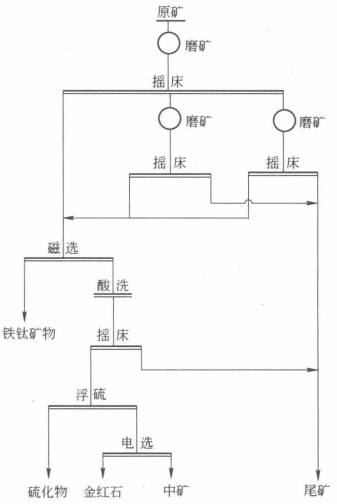

Shanxi Shangnan Rutile Mine, the main metal minerals in the ore include rutile, ilmenite, ilmenite, galena, pyrite, etc; Gangue minerals mainly include hornblende, biotite, feldspar, calcite, etc. The principle and process of mineral processing are as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Stepwise priority flotation process for copper ore

- Copper Ore Partial Mixed Flotation Process

- Iron Ore Weak Magnetic Beneficiation Process

- Cyanide Gold Preparation

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Sulfide Ore Nickel Ore Mixed Flotation Process

- Zirconium Ore Separation: Gravity and Magnetic Methods

Leave a message with your needs or comments

Add comment: