At present, more than 50 types of chromium containing minerals have been discovered in nature, belonging to the categories of oxides, chromates, and silicates; Chromite is currently the only mineral in industrial production, mainly composed of iron magnesium chromite, magnesium iron chromite, aluminum iron magnesium chromite, etc. The selectivity of chromite mainly depends on its grade, embedded particle size, and gangue composition. Currently, mineral processing methods include gravity separation, magnetic separation, electrical separation, flotation, roasting magnetic separation, etc.

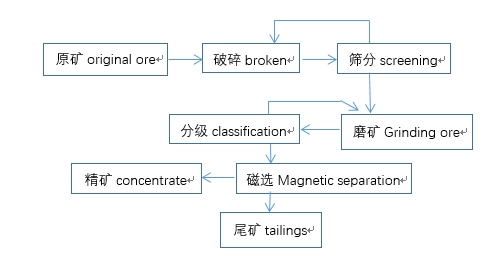

Magnetic separation process

Chromite has weak magnetism, so it can be separated through magnetic separation; Magnetic separation can be divided into two situations: one is to use weak magnetic separation to select strong magnetic minerals from chromite, and the other is to use strong magnetic separation to recover chromite.

Process characteristics

simple process, mature equipment, and low pollution.

Typical beneficiation plant

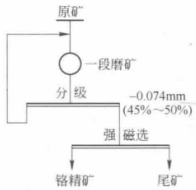

The Suolunshan Chromium Ore Dressing Plant in Inner Mongolia mainly produces chromium spinel and magnesite, followed by carbonate minerals and small amounts of quartz, serpentine, mica, zircon kaolin, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Gold Mine Combined Beneficiation Process

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Arsenic Gold Ore Bacterial Oxidation Pretreatment Process

- Zirconium Ore Processing: Gravity Separation and Flotation

- Manganese ore washing to achieve the best results

- Effective Flotation Processes for Copper-Molybdenum Ores

Leave a message with your needs or comments

Add comment: