Molybdenum is rarely distributed and relatively concentrated in nature. Currently, there are more than 20 known molybdenum minerals, including molybdenite, molybdenite, molybdenite, and calcium molybdate. These four types of molybdenum minerals are currently of industrial value; Molybdenite accounts for more than 98% of the world’s mining output, and the other three are secondary oxidation minerals of molybdenite. Molybdenum ore beneficiation should prevent over grinding, and the process generally adopts a multi-stage grinding and selection process. The conventional process is: rough grinding produces coarse concentrate, sweeping tailings to recover other metals, and the coarse concentrate is further ground in 2-3 stages and selected multiple times to obtain molybdenum concentrate.

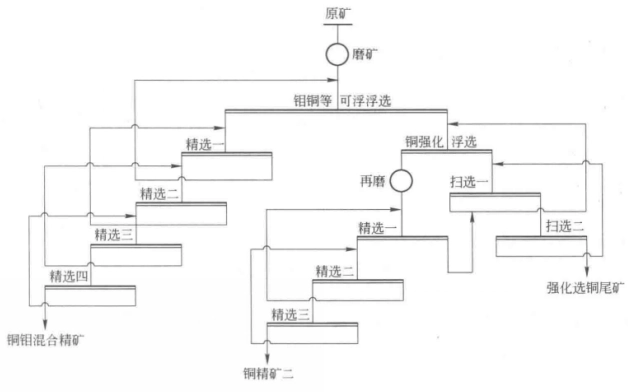

When processing copper molybdenum mixed ore in some beneficiation plants, copper minerals with similar floatability and molybdenite are first enriched in the same product, and then the remaining copper minerals are separately recovered. The copper molybdenum mixed concentrate is further processed.

Typical beneficiation plant

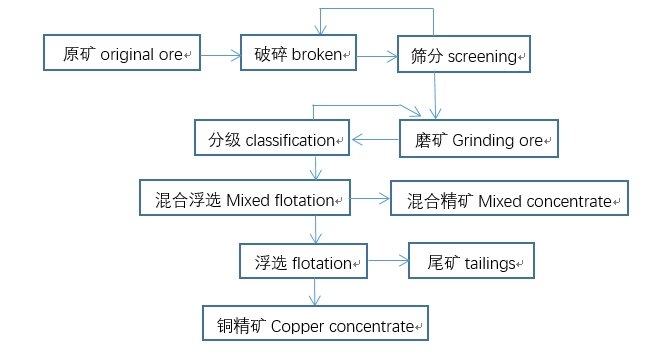

The Duobaoshan Copper Molybdenum Mineral Processing Plant is a typical porphyry type copper molybdenum deposit in China. The main metal minerals in the ore are pyrite, chalcopyrite, molybdenite, etc; Non metallic minerals mainly include quartz, plagioclase, sericite, chlorite, etc. The principle process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity separation+roasting+magnetic separation+gravity beneficiation process

- Laterite Nickel Ore: Pyrometallurgical Treatment

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Chromite Gravity and Magnetic Separation Process

- Titanium Ore Processing: Gravity, Magnetic, Flotation, Electric Separation

- Rutile Electric Separation, Magnetic Separation, and Gravity Selection Process

- Tantalum-Niobium Ore Gravity Separation Methods

Leave a message with your needs or comments

Add comment: