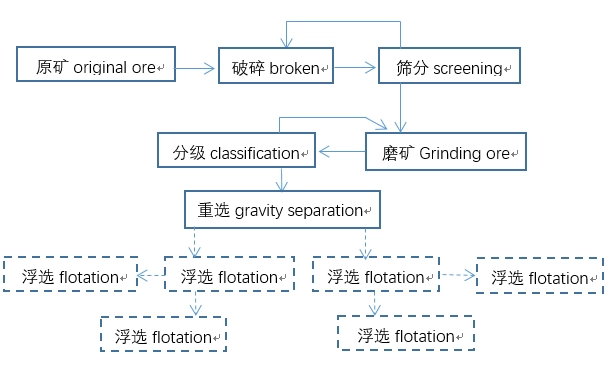

Gravity separation obtains crude concentrate products and fine mud products, and then partially or completely floats them separately to separate sulfides from cassiterite in the crude concentrate. Fine tin minerals in the fine mud are recovered through flotation enrichment.

Tin ore gravity+flotation process flow

1.Raw ore crushing:Crush the tin ore raw to a certain particle size to prepare for subsequent grinding and gravity beneficiation.

2.Grinding:Grinding the crushed raw ore to achieve appropriate fineness, providing conditions for gravity beneficiation.

3.Gravity beneficiation:

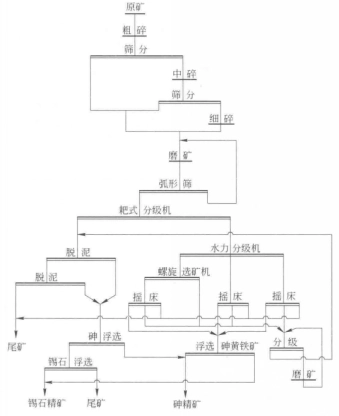

Classification:Use a hydraulic classifier to classify the slurry and separate different particle sizes of ore.

Jig Sorting:Coarse grade ore is sorted by gravity using a jigger to obtain coarse concentrate products.

Shaker sorting:Fine grained mineral sand is subjected to finer gravity sorting through a shaker to obtain fine mud products.

4.Flotation:

Coarse concentrate flotation:The coarse concentrate obtained from the jigging machine is subjected to flotation, and appropriate reagents (such as yellow medicine, black medicine, etc.) are used to separate sulfides and cassiterite.

Fine mud flotation:The fine mud obtained from the shaking table is subjected to flotation, and fine tin minerals are enriched and recovered by adjusting the reagents and process conditions.

5.Concentrate Treatment:The flotation concentrate is processed through concentration, drying, and other processes to obtain the final tin concentrate product.

Technological advantages

1Efficient Separation :Gravity beneficiation can effectively separate cassiterite from other minerals, especially for coarse-grained minerals. The flotation process can further enrich fine-grained tin minerals, and the combination of the two processes achieves efficient separation.

2.Resource recovery:Through gravity beneficiation, a large amount of cassiterite resources can be recovered, while flotation technology can recover fine-grained tin minerals, improving resource utilization efficiency.

3.Energy saving and environmental protection :The gravity beneficiation process has relatively low energy consumption, and the flotation process can also achieve energy-saving goals. Meanwhile, the combination of the two processes reduces the generation of tailings, which is beneficial for environmental protection.

4.Flexible Adaptation:Gravity beneficiation and flotation processes can be flexibly adjusted according to different ore properties and target products to achieve the best beneficiation effect.

5.Improve product quality:By combining gravity beneficiation and flotation processes, high-quality concentrate products can be obtained, which is beneficial for subsequent smelting and processing processes.

The combination of gravity beneficiation and flotation technology for tin ore is an efficient, energy-saving, and environmentally friendly beneficiation method that can achieve high recovery rates of tin ore resources and the production of high-quality products.

Typical beneficiation plant

Adentenberg beneficiation plant: The ore mainly consists of two types: biotite granite and quartz mica biotite. The main tin bearing mineral is cassiterite, while the vein minerals are mainly quartz, potassium feldspar, mica, and topaz.

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Gold Mine Combined Beneficiation Process

- Gold Ore Carbon Slurry Beneficiation Process

- Carbon leaching beneficiation process for gold mines

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Nickel Ore Mixing and Separation Flotation Process

- Efficient purification of manganese ore by magnetic separation process

Leave a message with your needs or comments

Add comment: