Electric separation is mainly used as an auxiliary method in tin ore beneficiation to further improve the concentrate grade, and its application is relatively limited.

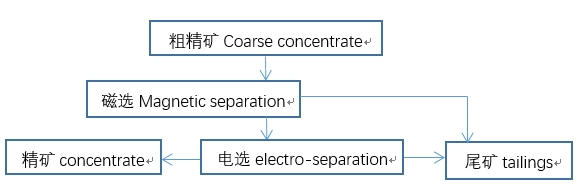

Tin ore magnetic separation+electric separation process flow

1. Raw ore crushing:Crush the tin ore raw ore to a certain particle size to prepare for subsequent grinding and beneficiation.

2.Grinding:Grinding the crushed raw ore to achieve appropriate fineness, providing conditions for magnetic and electrical separation.

3.Magnetic Separation:Magnetic separation is performed on the ground slurry, using a magnetic separator to separate magnetic minerals from non-magnetic minerals. Magnetic separation is a commonly used method in tin ore beneficiation, which can effectively improve the purity of cassiterite.

4.Electric selection:Perform electrical separation on the concentrate after magnetic separation. Electric separation is a method of separating mineral particles according to their electrical properties using electric field forces. In tin ore beneficiation, electric separation is mainly used to further purify cassiterite and improve the concentrate grade.

5.Concentrate Treatment :The concentrate obtained from electrical separation is processed through concentration, drying, and other processes to obtain the final tin concentrate product.

Technological advantages

1.High grade purification:As an auxiliary method, electric separation can further improve the grade of tin concentrate on the basis of magnetic separation.

2.Resource Recycling:This process can efficiently recover cassiterite resources and improve resource utilization through a combination of magnetic and electric separation.

3. Improve product quality :By combining magnetic and electric separation, high-quality concentrate products can be obtained, which is beneficial for subsequent smelting and processing processes.

4.Flexible Adaptation:According to the different properties of the ore and the target product, the process flow can be flexibly adjusted to achieve the best beneficiation effect.

5.Energy saving and environmental protection:Magnetic and electric separation processes have relatively low energy consumption, and at the same time, this process reduces the production of tailings, which is beneficial for environmental protection.

The tin ore magnetic separation+electric separation process is an effective beneficiation method for improving the grade of tin concentrate. Although it is less commonly used in tin ore beneficiation, it has important significance in specific situations.

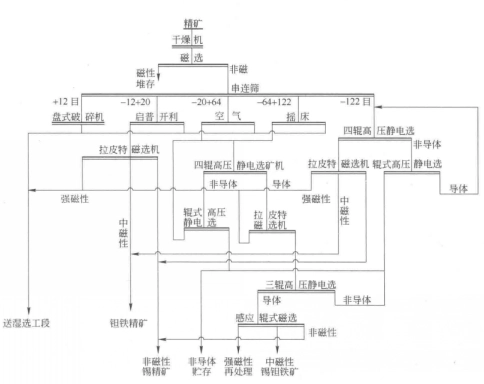

Typical beneficiation plant

Greenwich tin tantalum beneficiation plant: After the raw ore is re selected to obtain coarse concentrate, it enters the concentrate dry separation workshop and uses the magnetic separation electric separation process to obtain tin concentrate and tantalum iron ore concentrate, respectively.

- Random article

- Popular articles

- Popular comments

- Hg-ore Gravity selection+flotation process

- Iron ore positive flotation process

- Processing Lithium Ore: Artificial Selection, Gravity Separation, Flotation

- Zirconium Ore Separation: Gravity and Magnetic Methods

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Combined Process for Manganese Ore Magnetic Separation and Flotation

- Copper-Molybdenum Ore Separation & Flotation Process

Leave a message with your needs or comments

Add comment: