At present, there are more than 20 known types of mercury minerals in nature, and the main ones with mining value as industrial raw materials are cinnabar and black cinnabar; Chensha rich ore can be directly smelted in the furnace, while lower grade ore needs to be enriched through beneficiation before entering the smelting process. At present, most ore dressing plants use single flotation and heavy flotation combined processes, and a few individual mines still use manual selection.

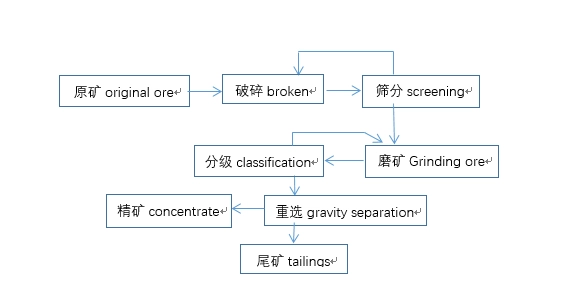

Gravity beneficiation process

Cinnabar has a high density, making it easy to use the re selection method for processing. However, in production practice, a single gravity separation process is generally not used to treat mercury ore. The reason for this is twofold: firstly, due to the fact that cinnabar is often imbued with uneven distribution of coarse and fine particles or fine particles, it is difficult to fully and effectively recover fine-grained cinnabar during the re selection process; Secondly, due to the brittleness of cinnabar and its good natural floatability, the fine-grained cinnabar produced during the grinding process is prone to floating on the water surface and being lost during re selection. Therefore, the re selected tailings are often subjected to flotation treatment after classification and re grinding.

Therefore, mercury ore beneficiation plants often use a combined heavy and floating process. Re selection is only used to recover a portion of coarse-grained cinnabar that has been dissociated from monomers, or to select a portion of cinnabar products from it. Shakers and jigs are the most commonly used methods for the re selection of mercury ore. The shaking table can obtain high-quality concentrate for the production of cinnabar products. Jigs are mostly used to process the undersized particle size of ore pre screened before entering the mill, or set in the grinding and classification circuit to timely recover the dissociated cinnabar to avoid over crushing. At the same time, a portion of coarser cinnabar products can also be recovered from the jigging concentrate. In recent years, some beneficiation plants have been using jigs to replace rough selection shakers.

Process characteristics

Short process, simple operation, and no need for chemicals.

- Random article

- Popular articles

- Popular comments

- Iron ore reverse flotation process

- Iron Ore Roasting and Magnetic Separation Process

- Sand gold beneficiation process

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Flotation Methods

- Effective Gravity Beneficiation for Chromium Ore

Leave a message with your needs or comments

Add comment: