At present, there are more than 20 known types of mercury minerals in nature, and the main ones with mining value as industrial raw materials are cinnabar and black cinnabar; Chensha rich ore can be directly smelted in the furnace, while lower grade ore needs to be enriched through beneficiation before entering the smelting process. At present, most ore dressing plants use single flotation and heavy flotation combined processes, and a few individual mines still use manual selection.

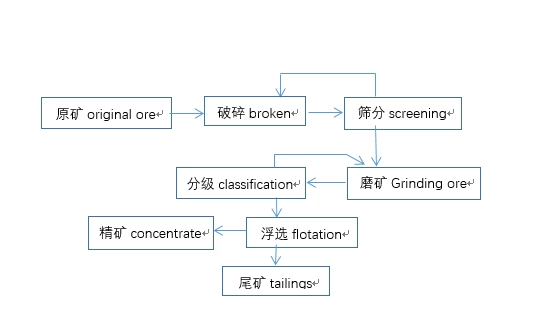

Flotation process

Flotation is the most commonly used and effective beneficiation method in mercury ore beneficiation. Flotation not only effectively recovers cinnabar from ores, but also effectively recovers various mercury minerals such as natural mercury and chloride sulfide mercury ore. Flotation is also used to treat polymetallic ores containing mercury. The main target mineral in the vast majority of mercury ores is cinnabar. Cinnabar has good natural floatability, therefore, the flotation process and reagent system for a single type of cinnabar ore are relatively simple. The commonly used process is one or two stages of grinding, with a graded overflow particle size of -0.074mm accounting for 85%, and some flotation plants have coarser flotation particle sizes. The flotation process often uses primary roughing, primary to secondary selection, and secondary to tertiary sweeping; Flotation reagents often use heavy metal salts as activators for cinnabar, such as copper sulfate, lead nitrate, lead acetate, mercury chloride, etc. Copper sulfate is most widely used, with a general dosage of 100-300g/t, and some beneficiation plants do not use activators. The collector of cinnabar is a type of yellow medicine. Ethyl yellow medicine is commonly used in domestic factories, with a dosage of 80-240g/t. Some selection factories have used a mixture of yellow medicine and black medicine, and their selection indicators are almost the same as when using yellow medicine alone.

Process characteristics

high comprehensive recovery rate and high concentrate grade.

Typical beneficiation plant

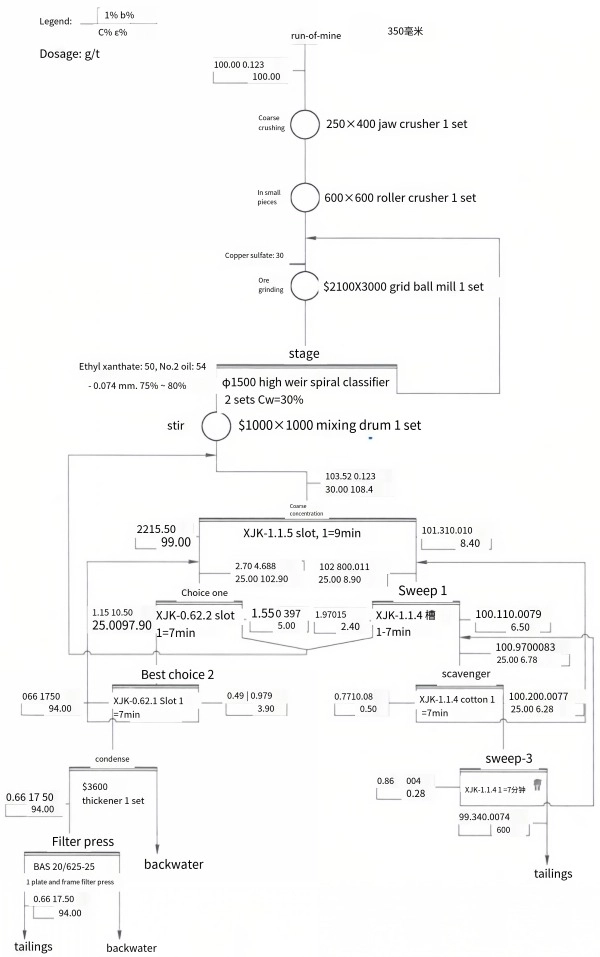

The Wuchuan Mercury Mine beneficiation plant eats ore with a grade of 0.1-0.2%. The ore is almost entirely carbonate, and the mercury mineral is mainly cinnabar, with very little content of other minerals; The main gangue minerals are calcite and dolomite. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Reverse flotation beneficiation process for bauxite

- Prioritized Flotation Process for Lead-zinc Ore

- Lead-zinc Ore Asynchronous Flotation Process

- Lithium ore heavy medium beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- chrome ore processing:Advanced Magnetic Separation Processing Technology

- Chromium Ore Gravity Separation and Flotation Process

Leave a message with your needs or comments

Add comment: