Single lead ore or zinc ore is very rare, commonly including lead zinc ore, lead zinc sulfide ore, lead zinc fluorite ore, etc; The commonly used beneficiation processes for lead-zinc mines can be divided into direct priority flotation, mixed separation flotation, equal floatability process, asynchronous flotation, and heavy flotation combined process.

The commonly used flotation collectors include xanthate, black medicine, sulfur nitrogen, fatty acids, amines, and chelating collectors; Adjusting agents include sodium sulfide, lime, copper sulfate, zinc sulfate, water glass, sodium sulfite, sodium thiosulfate, sulfuric acid, carboxymethyl cellulose, etc.

Priority flotation process flow of lead zinc ore

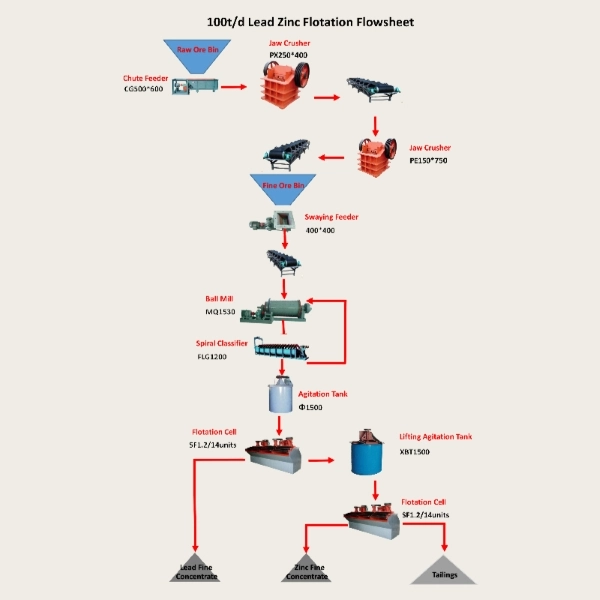

1.Ore preparation: Crushing and grinding the ore to achieve a certain fineness, which is beneficial for the subsequent beneficiation process.

2.Zinc suppression and floating lead:Adding zinc suppressants such as sodium cyanide and zinc sulfate to the slurry can generate insoluble substances on the surface of zinc minerals, thereby inhibiting their flotation. Then add activators such as copper sulfate, ammonium sulfate, etc. to activate the surface of lead minerals and facilitate flotation. Obtain lead concentrate with high lead content through one or more floatations.

3.Activated zinc selection:Adding activators such as copper sulfate and ammonium sulfate to the slurry can activate the surface of zinc minerals and facilitate flotation. Then, through one or more floatations, a zinc concentrate with high zinc content is obtained.

Characteristics of preferential flotation process for lead-zinc ore

1.Selective separation:Priority flotation technology can effectively separate lead and zinc metals. By adjusting flotation conditions such as reagent type and concentration, pH value, temperature, etc., selective flotation of lead and zinc minerals can be achieved.

2.Efficient and energy-saving:Compared with a single flotation process, priority flotation process can more efficiently recover valuable metals while reducing energy consumption.

3.Improve recovery rate:Priority flotation process can improve the recovery rate of lead and zinc, thereby increasing the utilization rate of the entire ore

4.flexibility:This process has high flexibility and can adjust the flotation conditions and sequence based on the specific properties of the ore and the flotation properties of lead and zinc metals to adapt to different ore types and metal compositions.

The advantages of the lead zinc priority flotation process are that the process is simple, the reagent conditions are easy to control, the indicators are stable, and a single mineral concentrate product can be directly obtained. This process is conducive to the separation of useful minerals and between useful minerals and gangue minerals, generally resulting in high-quality concentrate. For ore dressing plants with small production capacity, the direct priority flotation process is more suitable.

Typical beneficiation plant

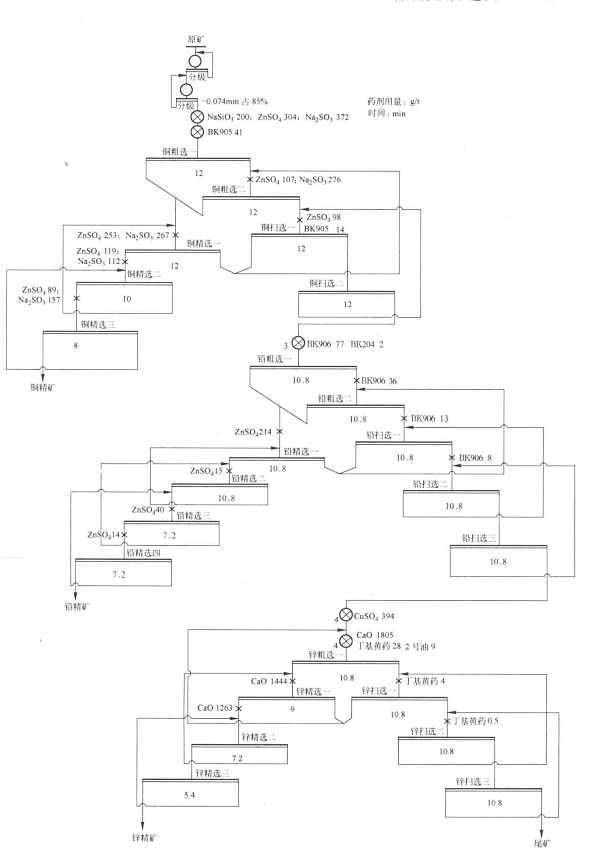

Sichuan Gacun Silver Polymetallic Mine Dressing Plant: The Gacun Silver Polymetallic Mine is located in the Garze Tibetan Autonomous Prefecture of Sichuan Province and belongs to a jet sedimentary deposit. The main useful minerals in the ore are sphalerite, pyrite, and galena. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity separation+flotation+gravity separation process

- Iron ore reverse flotation process

- Gold Mine Heap Leaching: Optimal Process

- Arsenic Gold Ore Wet Chemical Pretreatment Process

- Scheelite Flotation Method

- Lead zinc ore mixing+separation flotation process

- Lithium Ore Processing: Gravity Separation and Flotation

Leave a message with your needs or comments

Add comment: