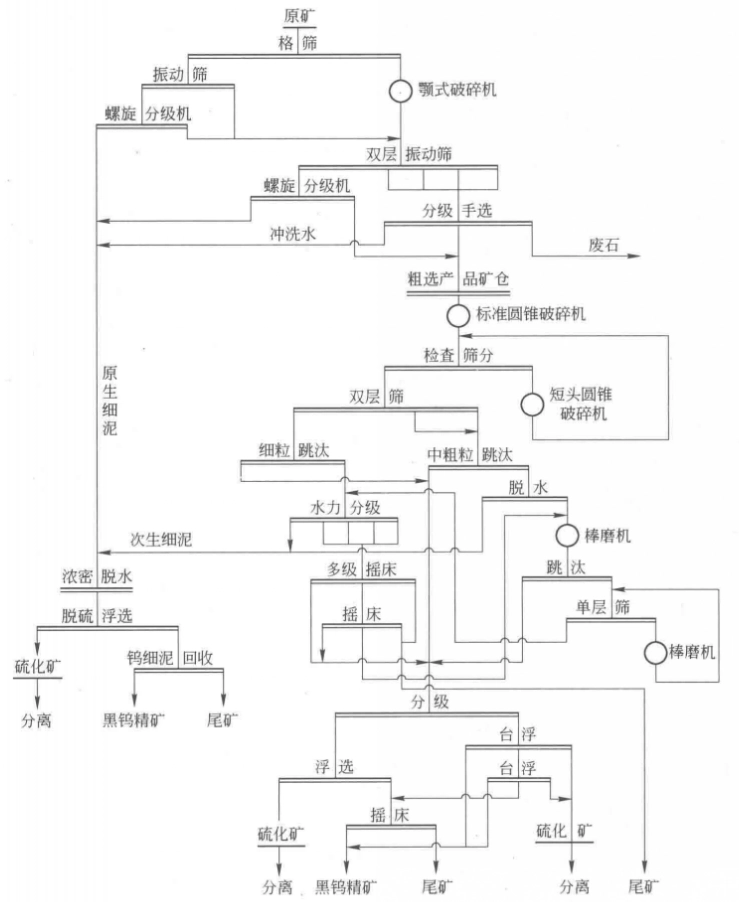

Black tungsten ore is generally a quartz vein type or fine vein type deposit. Black tungsten ore is often enriched in coarse plate-like or fine vein like crystals within quartz, with coarse embedded particle size and easy separation. For the coexisting gangue minerals, the density of scheelite is relatively high, and a combined beneficiation method mainly based on gravity separation is generally adopted. The process is divided into coarse selection, gravity separation, selection, and fine mud treatment.

Gravity combined beneficiation process for wolframite ore

1.Pre enrichment:In the beneficiation process, pre enrichment can improve the efficiency of subsequent operations and reduce processing capacity. The pre enrichment methods include gravity separation, magnetic separation, and flotation.

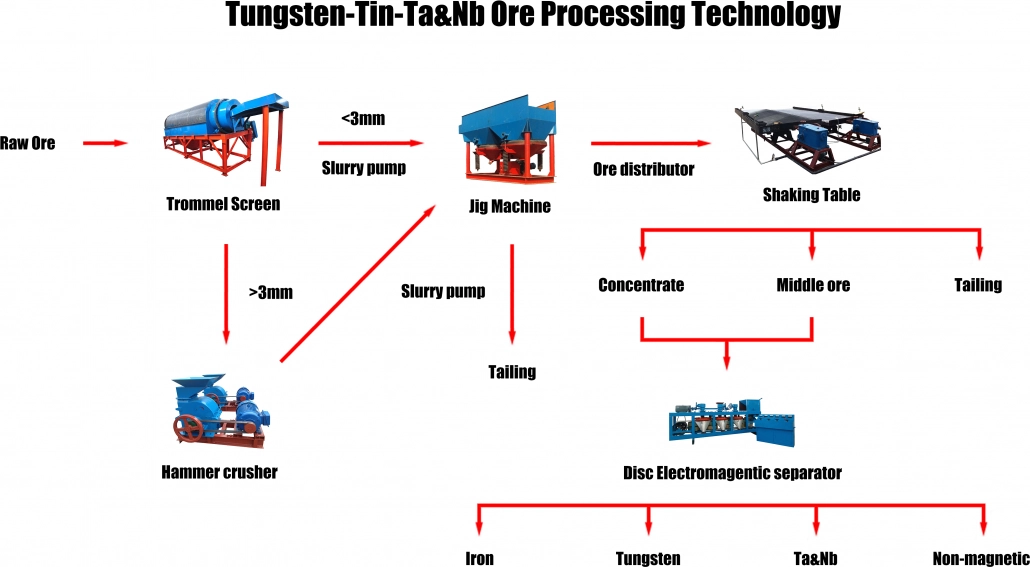

2.Gravity beneficiation process:Generally, a process of multi-stage jigging, multi-stage shaking table, and intermediate ore regrinding is adopted. After being finely crushed, the qualified ore is classified by a vibrating screen and subjected to multi-stage jigging to produce jigging and heavy selection coarse sand. Coarse sized jigging tailings are fed into a rod mill for re grinding, while fine sized jigging tailings are graded by a hydraulic classifier and enter a multi-stage shaking table for coarse and sweeping to produce shaking table heavy selection coarse sand. The shaking table tailings are discharged into the tailings pond, and the ore in the shaking table is returned for re grinding and re selection. The heavy selection coarse sand from jigging and shaking tables enters the selection operation.

3.Selection process:Generally, multiple separation processes such as floating heavy combination or floating heavy magnetic combination are used, and the associated elements are recovered in the selection stage. By using coarse and fine particle stage flotation and machine flotation to remove sulfide ore, the stage flotation and machine flotation sulfide ore are combined to enter the sulfide ore flotation separation. The stage flotation and machine flotation black tungsten ore are further produced through gravity separation to produce black tungsten concentrate. If the black tungsten concentrate contains scheelite or cassiterite, the black tungsten concentrate, white tungsten concentrate, and tin concentrate are selected through combined processes such as gravity flotation or gravity flotation magnetic separation (electric separation).

4.Fine mud treatment:Fine mud treatment is the treatment of fine-grained minerals to improve the purity and recovery rate of the concentrate. The methods for treating fine mud include flotation, magnetic separation, chemical separation, etc.

It is suggested that in the actual production process, the first step is to conduct beneficiation tests on the black tungsten ore. Based on various factors such as its own ore properties, beneficiation plant conditions, investment budget, etc., a suitable black tungsten ore beneficiation process flow should be determined, and the black tungsten ore beneficiation equipment should be customized to achieve ideal beneficiation indicators and economic benefits.

Technological advantages

Pre selection, enrichment, and pre tailings disposal can reduce the amount of ore in subsequent operations, separate flotation of fine mud can reduce the impact of fine mud, and multi-stage crushing and grading can reduce mud loss.

Typical beneficiation plant

Pangushan Tungsten Mineral Processing Plant

- Random article

- Popular articles

- Popular comments

- Copper Ore Partial Mixed Flotation Process

- Magnetic separation and beneficiation process for bauxite

- Floatability flotation process for lead-zinc ore

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Uranium Ore Radioactive Treatment Process

- Chromite Gravity and Magnetic Separation Process

- Combined Process for Manganese Ore Magnetic Separation and Flotation

Leave a message with your needs or comments

Add comment: