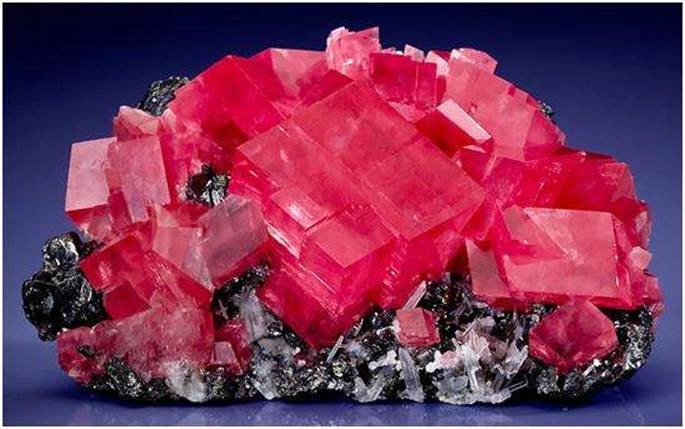

At present, more than 150 types of manganese minerals and manganese containing minerals have been discovered, with more than 20 commonly found, mainly including soft manganese ore, hard manganese ore, water manganese ore, black manganese ore, rhodochrosite, etc; The commonly used manganese ore beneficiation methods include washing, gravity separation, strong magnetic separation, flotation, pyrometallurgical enrichment, and hydrometallurgy.

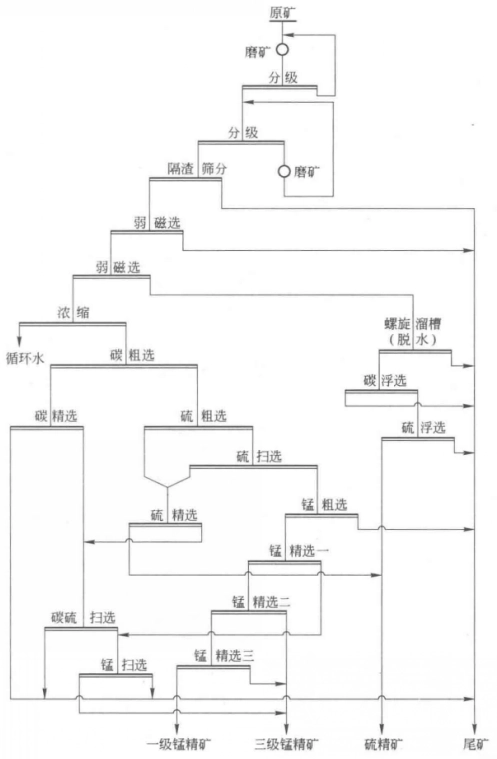

Magnetic separation has two different purposes: one is to separate iron and manganese through weak magnetic separation, and the other is to obtain high-grade manganese concentrate products through strong magnetic separation; Afterwards, flotation will be used for the next step of treatment on the manganese containing crude products.

The strong magnetic separation flotation method has good adaptability. The strong magnetic separator not only effectively removes the ore slurry, but also improves the selection grade of flotation. The use of strong magnetic flotation desulfurization can directly obtain comprehensive manganese concentrate products; By using sodium petroleum sulfonate instead of oxidized paraffin soap as a collector, the slurry can be sorted at neutral and room temperature, saving medication and energy consumption.

Typical beneficiation plant

The Zunyi manganese ore dressing plant has a manganese grade of 15% -25%, iron content of 9% -10%, an average phosphorus content of about 0.05%, and an average sulfur content of about 4.5%. It is a semi self melting manganese ore with low manganese, low phosphorus, high iron, and high sulfur; Manganese minerals mainly include calcium rhodochrosite, rhodochrosite, manganese calcite, manganese siderite, water manganese ore, etc. Gangue minerals mainly include mica, chlorite, kaolinite, quartz, etc. The specific process is as follows:

- Random article

- Popular articles

- Popular comments

- Selective flocculation beneficiation process for bauxite

- How to Extract Gold Using Mercury

- Arsenic Gold Ore Oxidation Roasting Pretreatment Process

- Combined process of laterite nickel ore selection and smelting(oxidized ore)

- Radioactive beneficiation and flotation process for uranium ore

- Complete Manganese Ore Gravity Separation Process

- Manganese Ore Reduction Roasting and Magnetic Separation Process

Leave a message with your needs or comments

Add comment: