Tungsten is a rare metal that is widely distributed and almost exists in various types of rocks. Due to its low content, it can only be enriched through relevant geological processes to form mineral deposits for mining. At present, more than 20 types of tungsten ores have been discovered in nature, among which the mining value of scheelite and wolframite is higher, and they are also the main sources of tungsten resources

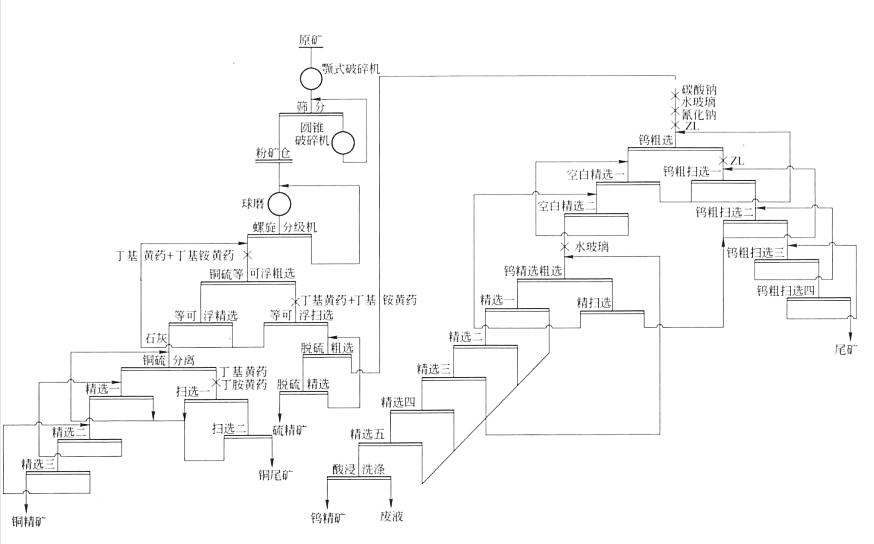

Scheelite flotation is a commonly used beneficiation method, generally used to treat ores containing scheelite. The flotation process of scheelite is generally divided into three stages: sulfide ore flotation, tungsten rough selection, and selection.

Flotation process of scheelite

Scheelite has good natural floatability, and its flotation process can be roughly divided into two parts: rough selection and selection. Rough selection mainly aims to maximize the recovery rate of scheelite, while selection is to obtain qualified tungsten concentrate. In order to obtain qualified tungsten concentrate, multiple selections are often required to achieve the expected effect.

1.Rough selection of scheelite:Rough selection of scheelite: The commonly used method is the lime method, which uses the adsorption of calcium ions on the surface of gangue minerals to change the surface potential of the gangue minerals. Then, sodium carbonate is added to precipitate the calcium on the surface of the gangue minerals. The surface of scheelite also adsorbs calcium, but its surface charge remains negative and does not produce calcium carbonate precipitation. Therefore, adding inhibitors such as water glass only suppresses the gangue minerals and has no effect on scheelite, Thus achieving the separation of tungsten ore and gangue minerals.

2.Selection of scheelite ore:The key is to separate calcium containing gangue minerals from scheelite. The commonly used processes are room temperature method and heating method. The room temperature method has weak adaptability to ores, and the selection index fluctuates greatly. The grade of flotation scheelite concentrate is generally 55%~60%, with high impurities. Usually, the method of leaching with hydrochloric acid is used to recover more than 65% of tungsten concentrate.

Characteristics of scheelite flotation process

Taking into account the comprehensive recovery of scheelite and sulfide ore in the ore, while ensuring the grade of the concentrate and considering the recovery rate. In the flotation process, it is necessary to select appropriate collectors and adjusters based on the properties of the ore and the type of scheelite to achieve the best flotation effect. At the same time, strict control of the flotation process is also necessary to ensure the stability and reliability of the flotation process.

Typical beneficiation plant

Xianglushan Tungsten Industry scheelite beneficiation plant: The deposit is a skarn type scheelite polymetallic deposit, with scheelite as the main metal mineral and associated minerals including chalcopyrite, magnetite, pyrite, sphalerite, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Gold selection process using resin slurry method

- Gold Ore Carbon Slurry Beneficiation Process

- Lithium ore positive flotation process

- Antimony Ore Hand Picking Process for Color Sorting

- Manganese Ore Separation: Gravity and Magnetic Methods

- Rutile Gravity Separation, Magnetic Separation, and Flotation Process

- Barite Combined Beneficiation: Key Process Insights

Leave a message with your needs or comments

Add comment: