Black and white tungsten mixed ore is a difficult to select ore, with generally low grade, fine embedded particle size, and complex gangue minerals. Therefore, complex process flow is usually required for processing. The process characteristic of processing black and white tungsten mixed ore is to comprehensively recover co occurring minerals on the basis of fully recovering black tungsten ore and white tungsten ore separately.

Gravity combined beneficiation process for black and white tungsten ore

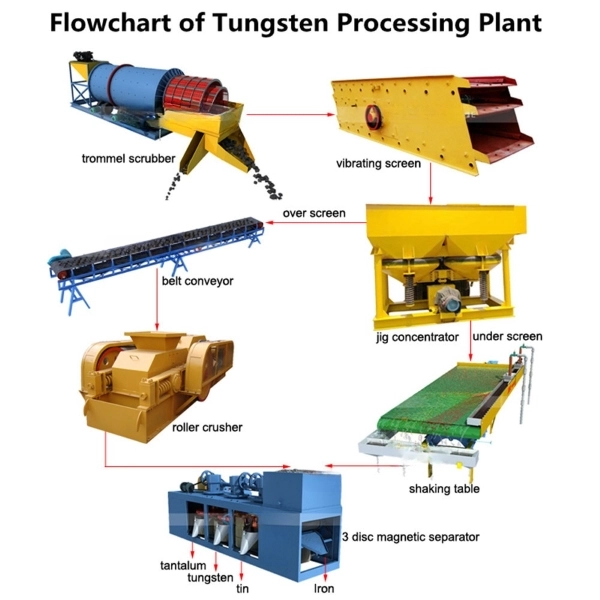

1.Preprocessing:The pre-treatment stage includes steps such as crushing and grinding, breaking the ore into smaller particle sizes for subsequent beneficiation operations.

2.Gravity beneficiation:Re selection is one of the main methods for beneficiation of black and white tungsten mixed ores. By using reselection methods such as jigging and shaking, wolframite and scheelite can be preliminarily separated based on differences in mineral density.

3.flotation:Flotation is one of the commonly used methods in the beneficiation of black and white tungsten mixed ores. Through flotation, wolframite and scheelite can be further separated based on the surface properties of minerals and the selection of flotation reagents. The commonly used flotation reagents include collectors and adjusters.

4.Selected:Selection is the further treatment of minerals after flotation to improve the grade and recovery rate of the concentrate. The selected methods include heated flotation, room temperature flotation, etc.

5.Comprehensive recycling:In the beneficiation process of black and white tungsten mixed ore, in addition to recovering wolframite and scheelite, it is also necessary to comprehensively recover coexisting minerals. This can be achieved by adjusting the selection of flotation reagents and process parameters.

When dealing with mixed black and white tungsten ore, it is necessary to comprehensively consider factors such as the properties of the ore, the embedded particle size of minerals, and the complexity of gangue minerals, and choose appropriate beneficiation methods and process flows. At the same time, it is necessary to strictly control the beneficiation process to ensure the stability and reliability of the beneficiation effect.

Typical beneficiation plant

Shizhuyuan Nonferrous Metal Polymetallic Mineral Processing Plant: The plant mainly produces tungsten, molybdenum, bismuth, iron, and pyrite, etc; Tungsten minerals include scheelite, scheelite, wolframite, etc. The specific process is as follows:

For more professional suggestions? Contact us!

Warm Tips:If you want to know more information, like quotation, products, solutions, etc.,

Contact: Pingheng

Tuxing Sun Mineral Processing Expert

Wechat/whatapp:+86 18092529083

Email:[email protected]

- Random article

- Popular articles

- Popular comments

- Tin ore gravity+flotation process

- Prioritized Flotation Process for Lead-zinc Ore

- Nickel ore priority flotation process(Sulfide ore)

- Lithium ore combined beneficiation process

- Zirconium Ore Processing: Gravity, Magnetic, and Electric Separation

- Chromite Gravity, Magnetic, and Electric Separation Process

- Complete Manganese Ore Gravity Separation Process

Leave a message with your needs or comments

Add comment: